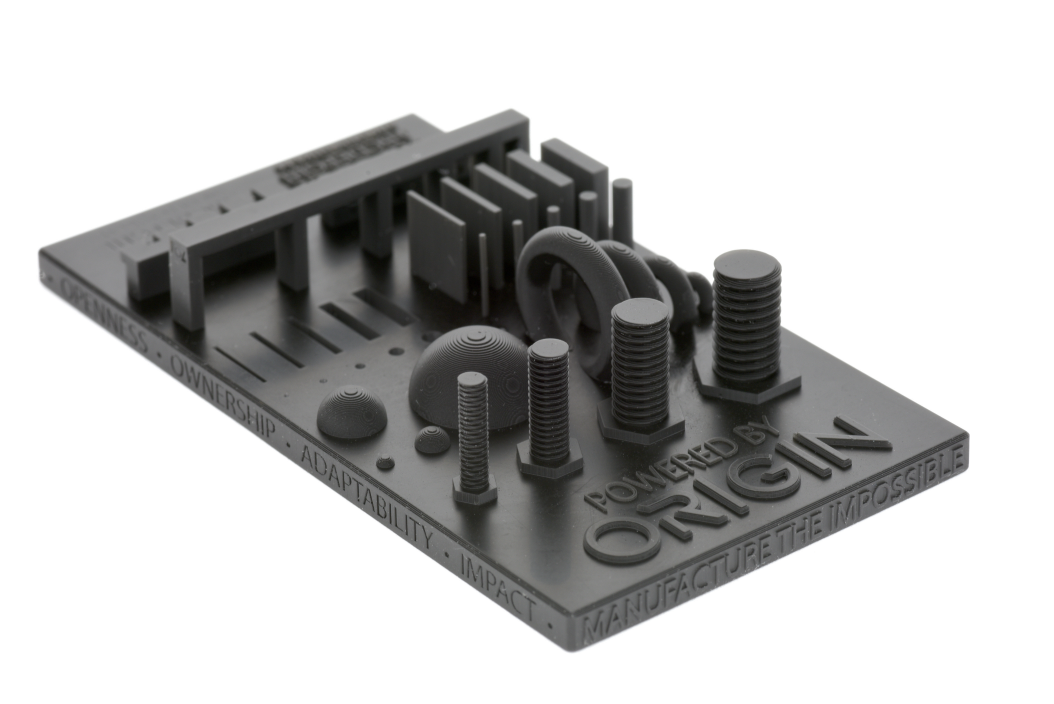

Production P3

Get ready for a new era of 3D printing.

Programmable PhotoPolymerization P3™ technology, an evolution of digital light processing (DLP) is ushering in a new era in 3D printing: the mass production of functional end-use parts.

P3 software precisely orchestrates light, temperature, pull forces and pneumatics to optimize prints for the best possible results. With P3, manufacturers can achieve injection molding part quality and surface finish with incredible accuracy, in a diverse and continuously growing range of high-performance materials.

What makes P3 unique?

P3 is a combination of several tightly controlled, programmable steps in the printing process. P3 extends DLP printing’s capabilities and supports the next generation of production applications made with photopolymers. This powerful combination of production-grade technology and performance materials unlocks functional end-use applications in 3D printing with competitive throughput and part cost.

How it works:

Four critical parts of the P3 process enable the unique combination of high throughput, production-grade part quality and materials.

- Light: Programmable light sets off an exothermic reaction that forms layers with outstanding resolution, accuracy and dosage control.

- Environmental stability: Temperature-controlled printing mitigates warping and shrinkage, while unlocking materials with advanced properties, like flame retardancy.

- Pneumatic separation: A perfectly timed separation procedure reduces pull forces, leading to a molded-like surface finish, high-throughput and ultra-fine features, such as textures or large surface areas like molds.

- Motion: Precise control over printer movements ensures a repeatable, fast and accurate workflow in a wide range of geometries and high-performance materials.

- Green Strength: The P3 process produces a high polymerization conversion, unlocking faster print times, extreme geometries, and build nesting.

Materials

-

This tough, high-temperature material is perfect for molds and end-use parts with up to 80°C operating temperature. Achieve outstanding surface finish and dimensional accuracy with ease. Whether for interior automotive components or high-modulus demanding applications, LOCTITE® 3D IND403 High Modulus by Henkel is your reliable solution for superior performance.

-

Somos® QuickGen 500 has unique flexibility; it is more flexible than other resins but stiffer than elastomers, offering both flexibility and spring back.

-

Durable, tough, and impact-resistant material, for functional applications that must perform under stress and high load conditions.

-

Single component elastomer with high resilience and rebound. Capable of maintaining excellent tensile strength and does not require thermal post-processing. It is comparable to commercial TPUs, with a Shore A hardness of 75.

-

LOCTITE 3D MED 412 by Henkel is a medical-grade resin designed as a strong, durable material with excellent elongation, impact, and compression strength, to enable manufacture medical parts that require moderate stiffness and wear resistance.

-

P3 Deflect 120, Evonik's groundbreaking photopolymer, offers exceptional strength and heat resistance, making it the perfect choice for applications demanding both high-temperature resilience and good elongation at break. With its low viscosity and impressive green strength, P3 Deflect 120 is ideal for complex parts like wiring housings, connectors, and mold tooling. Elevate your 3D printing projects with this innovative material.

-

Stratasys open specialty materials unlock various demanding applications, including molding, casting, high-temperature, ceramic, electrostatic discharge (ESD), and elastic applications.