3D Printer Materials and Filament

To ensure ultimate performance and quality, we provide a robust range of advanced 3D printing materials and filaments in the below three distinctive tiers:

Stratasys Preferred

Preferred by Stratasys for its customers for the highest performance applications. These materials are engineered to provide the best combination of material and printer performance and are developed by Stratasys or third-party material partners.

Stratasys Validated

Materials validated by Stratasys with basic reliability testing to accelerate the expansion of material options available in the marketplace. These materials may or may not be exclusive to Stratasys.

Open License

Unvalidated materials accessed via an Open Material License (OML). These materials may offer unique attributes and the potential to address new applications. Still, they have not received validation testing or optimization relative to performance and functionality on a Stratasys printer.

Specifically created for tooling, functional prototyping, jigs & fixtures and end-use production parts, the Stratasys materials & filaments meet the most demanding industry standards.

-

With Stratasys FDM technology, making complex geometries and parts with internal cavities becomes possible. FDM thermoplastics deliver precise tolerances, durability, and stability in different environments.

-

Stratasys offers PolyJet technology 3D prints in the widest variety of materials, so you can create ergonomic tooling, bio-compatible surgical guides or realistic prototypes that closely resemble finished products.

-

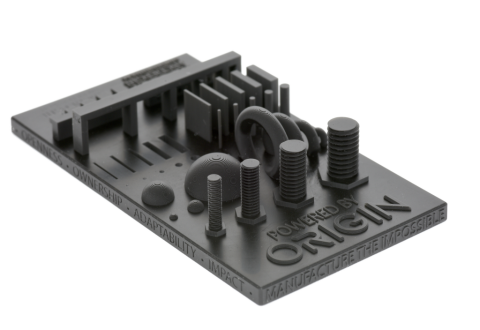

P3 General Purpose Photopolymers are fast printing materials for end-use applications requiring cosmetic surfaces, fine features, and high accuracy.

-

SAF™ Selective Absorption Fusion™ technology is the power behind the H Series™ Production Platform, designed for production-level throughput of end-use parts.

-

Stereolithography is an additive manufacturing process that uses a vat of liquid UV-curable photopolymer resin and a UV laser to build parts one layer at a time.