SAF™ Technology

Selective Absorption Fusion

The world is changing fast. Manufacturing is evolving - to be more resilient, more agile, and more adaptable. The H Series Production Platform from Stratasys gives you the additive production capabilities to emerge ahead.

The H Series Production Platform with SAF technology provides the accuracy, repeatability, and process control essential for consistent production and competitive part costs. Read our Solution Guide to go more in-depth about how the H Series platform with SAF technology is the optimal choice for producing additive-manufactured parts at scale.

What is SAF?

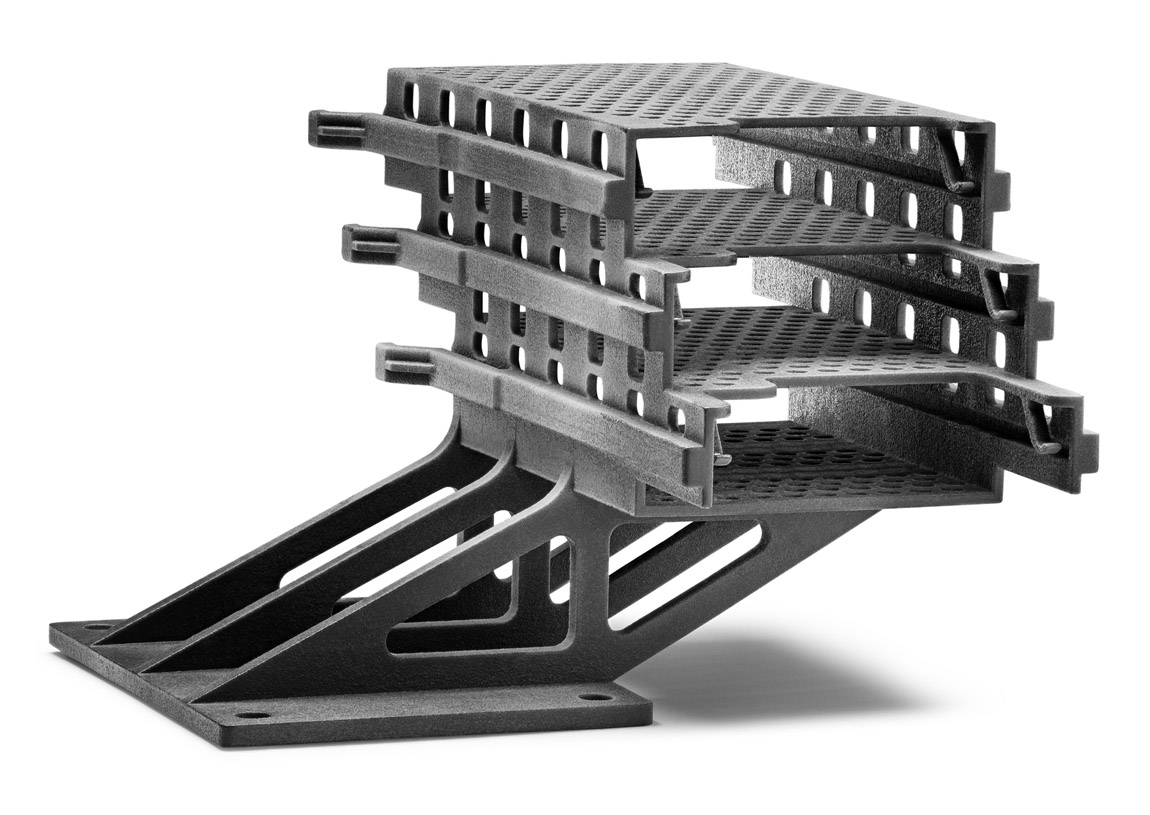

SAF technology empowers a powder-based additive manufacturing process that employs industrial-grade technology to achieve higher levels of production of end-use parts. SAF is the technology behind the upcoming H Series™ Production Platform that provides broad capability to control the print process to achieve accurate, consistent production at competitive part costs.

How it works:

SAF technology uses an infrared-sensitive HAF (High Absorbing Fluid) to fuse particles of polymer powder together in discreet layers to build parts. It uses Big Wave™ powder management, a proprietary technology that includes powder distribution across a bed, where industrial-grade Piezo-electric print heads jet the fluid in prescribed areas to create each layer of the part. This is followed by exposure to infrared energy, which causes the areas with HAF to melt and fuse together. The sequence is repeated until the parts are completed.

See also:

PolyJet Technology & Materials