Stratasys F900

Industrial Strength, Durability and Scale

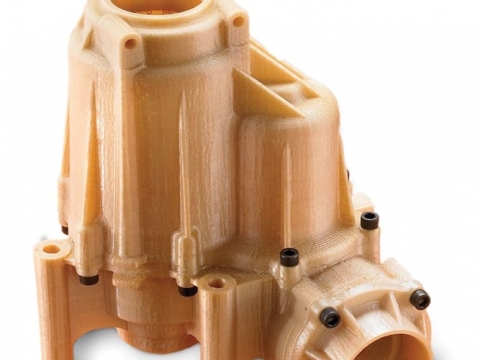

The F900 gives you the ability to create large parts or multiple smaller parts in the broadest array of FDM materials. With the largest build chamber available among FDM printers, the F900 enables additive manufacturing at scale while delivering consistent, accurate results.