Amatrol

Global Leader in CTE Courses

With a passion for excellence, Amatrol is helping build a culture that embraces change by doing the right thing, respecting others, being responsible, improving growth, and creating lasting partnerships.

Amatrol’s training solutions are used in all fifty states and over fifty countries. Their courses are not only engaging, but also customizable to allow programmers a one-of-a-kind interactive learning experience.

e-Learning Course ListAdvanced Manufacturing Skills ChartVisit Amatrol's Site

-

Item Number:950-GEO1Amatrol’s 950-GEO1 Geothermal Energy Training System enables learners to understand and apply their newly obtained technician skills in the ever-growing area of geothermal energy.

-

Item Number:950-GEO1DAmatrol’s 950-GEO1 Geothermal Energy Training System enables learners to understand and apply their newly obtained technician skills in the ever-growing area of geothermal energy.

-

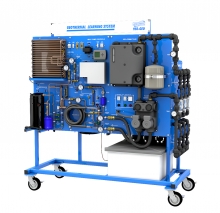

Item Number:950-GEO2DAmatrol’s 950-GEO2D Geothermal Troubleshooting Learning System with Desuperheater uses an exposed component layout so that learners can see each component’s role in a geothermal system.

-

Item Number:T7031With Amatrol’s Refrigerant Recovery and Charging Learning System for R-134a, you can train future HVAC/R technicians hands-on the critical technical skills required for a successful career. Students will work with real equipment, including a recovery machine, manifold gauges, submersible cooler, temperature probe, filter dryer, low side liquid charger, vacuum pump, and micron vacuum gauge.

-

Item Number:T7032Teach aspiring HVAC/R technicians the critical technical skills needed to succeed on the job with Amatrol’s Refrigerant Recovery and Charging Learning System for R-410a (T7032). Students will work with real equipment, including a recovery machine, manifold gauges, submersible cooler, temperature probe, filter dryer, liquid vaporizer, low side liquid charger, vacuum pump, and micron vacuum gauge.

-

Item Number:T7100Amatrol’s Residential Heat Pump Troubleshooting Learning System (T7100) is used to teach hands-on the critical skills HVAC/R technicians need to succeed when working with residential HVAC systems that use a heat pump and traditional ducting. Students will work with real equipment, including a heat pump condenser, heat pump air handler, Wi-Fi-enabled thermostat, fuse box, ducting, and manifold.

-

Item Number:T7130With Amatrol’s Residential Mini-Split Heat Pump Learning System (T7130) you can teach the critical hands-on technical skills HVAC/R technicians need when working with residential ductless (“mini-split”) HVAC systems. Students will work with real equipment, including a heat pump condenser, evaporator unit, thermostat, panel-mounted gauges, and condensate pump.

-

Item Number:950-SH1Amatrol’s Steam System Training System (950-SH1) introduces learners to the operation, installation, maintenance, and repair of steam systems and their application in paper mills, commercial and residential settings, power companies, and even nuclear submarines.

-

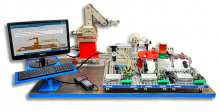

Item Number:T7081Understanding HVAC/R, geothermal, refrigeration, and steam systems requires a good hold on the basics. With Amatrol's T7081 Applied Thermal Science Trainer, you can provide the hands-on training your students or employees need.

-

High school students are destined to become knowledge workers, regardless of whatever specific career choice they make. Engineering and technology offer some of the most rewarding career opportunities possible! Amatrol’s high school programs are designed to engage students who demand a high degree of interactivity and challenge to keep them interested and learning. All of our high school programs articulate to colleges for up to 18 credit hours.