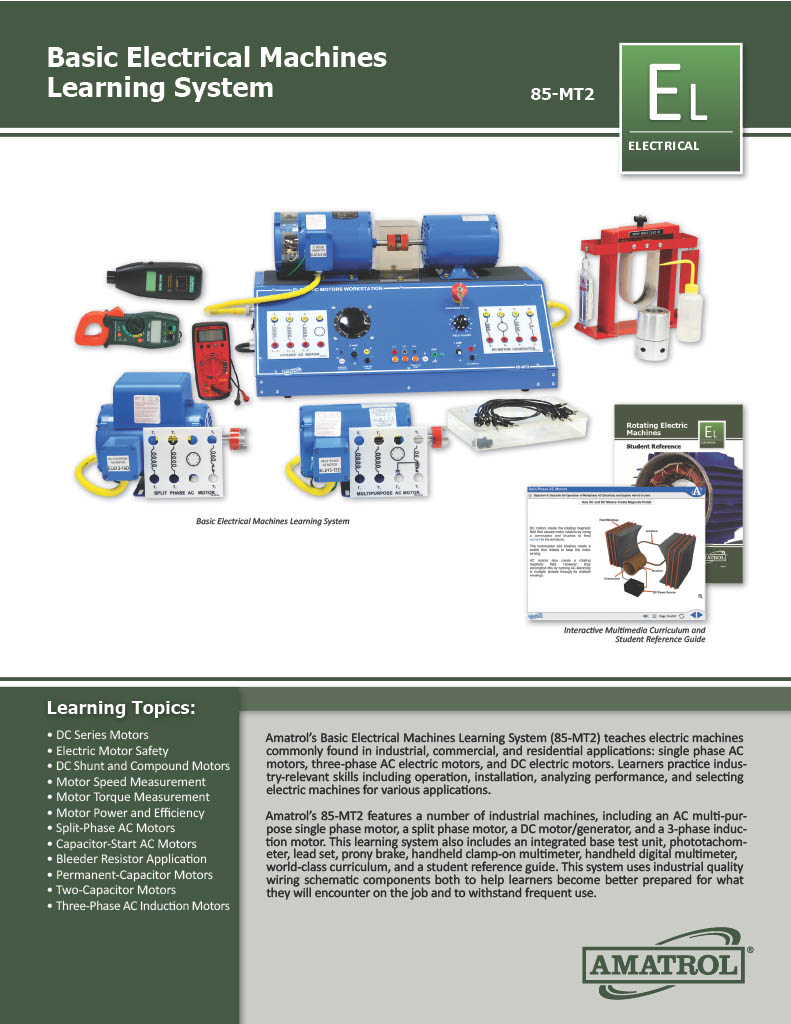

Amatrol’s Basic Electrical Machines Learning System (85-MT2) teaches electric machines commonly found in industrial, commercial, and residential applications: single phase AC motors, three-phase AC electric motors, and DC electric motors. Learners practice industry-relevant skills including operation, installation, analyzing performance, industrial motor wiring, and selecting electric machines for various applications.

The 85-MT2 features a number of industrial machines, including an AC multi-purpose single phase motor, a split phase motor, a DC motor/generator, and a 3-phase induction motor. This learning system also includes an integrated base test unit, lead set, prony brake, handheld clamp-on multimeter, handheld digital multimeter, world-class curriculum, and a student reference guide. This system uses industrial quality wiring schematic components both to help learners become better prepared for what they will encounter on the job and to withstand frequent use.

Amatrol’s DC Generators Learning System (85-MT2B) teaches industry-relevant DC generator skills, including how to operate, install, analyze performance, and select generators for various applications. A generator is a device that creates DC electricity and can be found in diesel locomotives, as well as aircraft and marine systems. The DC generators training system requires the Basic Electrical Machines Learning System (85-MT2), as well as 208 VAC/60 Hz/3 phase power.

This industrial motor training system includes resistive load and inductive load units that connect to the DC generator supplied with the 85-MT2 to provide operation under various types of loads. Learners will use these components to study topics such as DC series generators, DC shunt generators, and DC compound generators. Amatrol learning systems feature a perfect combination of theoretical knowledge and hands-on skill building to reinforce each in a learner’s mind and strengthen comprehension for more advanced skills.

Amatrol’s Alternator/Synchronous Motor Learning System (85-MT2C) adds to the Basic Electrical Machines Learning System (85-MT2) to teach skills related to alternators and synchronous motors commonly found in industrial applications. Alternators provide a mobile source of AC electrical power while synchronous motors reduce power costs by correcting the overall power factor in a plant. Learners will study industry-relevant skills in industrial motor training, including how to operate, install, and analyze the performance of alternators and synchronous motors.

The alternator and synchronous motor training system includes capacitive load, combination synchronous motor/alternator, and synchronizing lights/switch units. The capacitive load unit combines with the 85-MT2 to provide operation under various types of loads. In addition to industrial components, this training system includes in-depth curriculum, an instructor’s guide, and a student reference guide. The highly-interactive, multimedia curriculum covers major topical areas such as alternator output voltage and frequency, three dark synchronization method, and reversing a synchronous motor.

Amatrol’s Wound Rotor Motor Learning System (85-MT2D) covers the function, operation, and performance characteristics of wound rotor motors. While variable frequency drives (VFDs) and standard induction motors have replaced wound rotor motors in many applications, these motors are still used for heavy-duty, high torque applications such as industrial cranes and hoists. Amatrol’s wound rotor motor training system requires the Basic Electrical Machines Learning System (85-MT2) for use.

Wound rotor motor training includes a wound rotor speed controller, a wound rotor motor, banana leads, in-depth multimedia curriculum, an installation guide, and a student reference guide. These components will be used to study topics such as wound rotor speed control, performance characteristics, and motor reversing. Amatrol systems feature real-world, industrial-grade components for both durability and to facilitate learners in gaining hands-on practice with actual equipment that they’ll find in the field.

Amatrol’s Electric Motor Troubleshooting Learning System (85-MT2E), used in conjunction with the required Basic Electrical Machines Learning System (85-MT2), covers AC and DC motors troubleshooting and testing using a multimeter and a megger meter. The skills and knowledge covered by this system will prove invaluable for industrial maintenance technicians or anyone working in a field that uses AC and/or DC motors. This system covers major topics like AC and DC motor failures, common methods of diagnosing these failures by using a multimeter and megger meter, and troubleshooting these failures.

The 85-MT2E includes a motor connection box to practice hands-on skills, such as troubleshooting faults in a DC motor and AC single-phase and three-phase motors, evaluating DC electric motor commutator and brush health, and using a multimeter to test an AC motor start/run capacitor. Amatrol’s industrial training systems feature real-world, industry-grade components for durability that will stand up to frequent use and to allow learners to gain real-world competencies.

The AC Elector Motor Control Systems Trainer will give your students hands-on learning with motors found in industrial, commercial, and residential applications. It's versatile, comprehensive, and has eLearning built around it. Watch for a quick overview of the system.

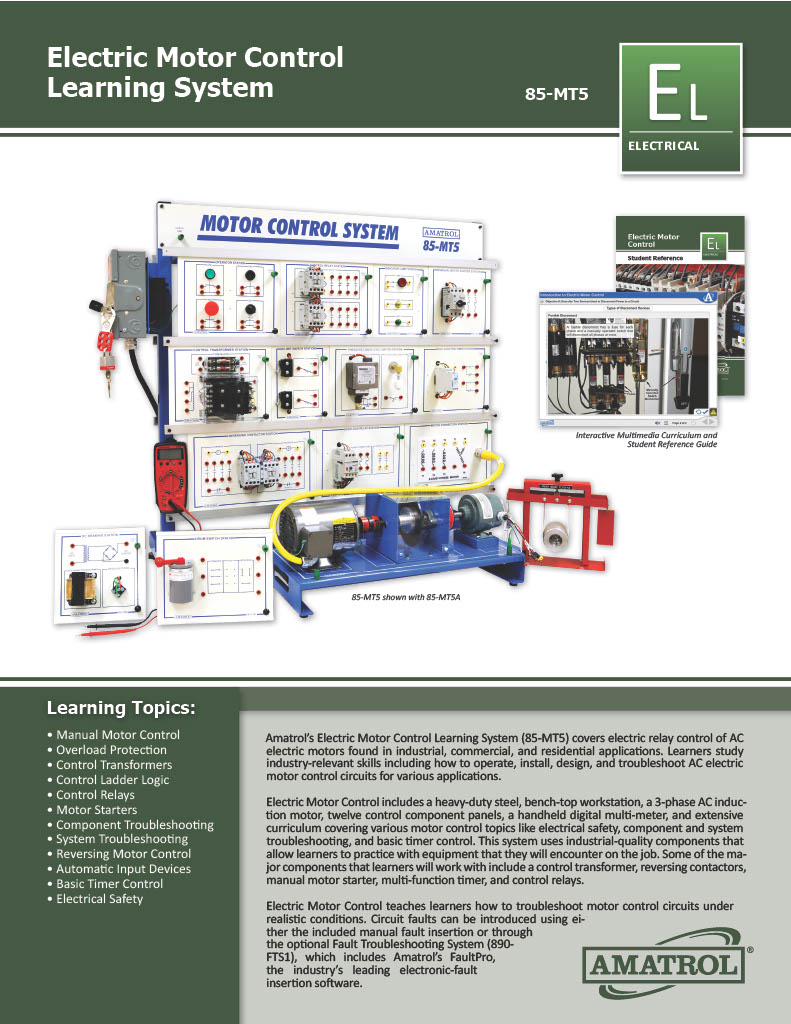

Amatrol’s Electric Motor Control Learning System (85-MT5) teaches electric relay control of AC electric motors found in industrial, commercial, and residential applications. Learners study industry-relevant skills including how to operate, install, design, and troubleshoot AC electric motor control circuits for various applications.

The 85-MT5 includes a bench top-mount control workstation, motor workstation, AC induction motor, control component panels, multimeter, lead set, and student curriculum that is unmatched within the industry. This system uses industrial-quality components to train learners to become better prepared for what they will encounter on the job. Some of the major components that learners will work with include a control transformer, reversing contactors, manual motor starter, multi-function timer, and control relays.

The 85-MT5 teaches learners how to troubleshoot motor control circuits under realistic conditions. Circuit faults can be introduced using either the included manual fault insertion system or through the optional Fault Troubleshooting System (890-FTS1), which includes Amatrol’s FaultPro, the industry’s only electronic-fault insertion software.

Amatrol’s Motor Braking Learning System (85-MT5A) adds to the Electric Motor Control Learning System (85-MT5) to expand a learner’s knowledge of the common electric motor braking methods found in industrial, commercial, and residential applications. Braking is essential to motor control when motors must be stopped and restarted multiple times. Common applications include rolling mills, conveyors, and power fans. Learners study industry-relevant skills for three of the most common braking methods: electromagnetic braking, plugging, and DC injection braking. Troubleshooting braking problems under realistic conditions allows learners to experience the challenge and reward that result from applied problem solving.

The motor braking training system includes a DC braking station with power supply, transformer and bridge rectifier mounted to a slide-in panel, inertial load module with flywheel, electromagnetic brake, plugging/anti-plugging switch, student curriculum, and instructor’s guide. This system uses industrial quality components that stand up to frequent use and enable learners to better prepare for what they will encounter on the job.

Amatrol’s Reduced Voltage Starting Learning System (85-MT5B) adds to the Electric Motor Control Learning System (85-MT5) to teach methods of starting electric motors under reduced voltage, 3-phase power distribution using Delta and Wye transformer wiring configurations, and troubleshooting. Reduced voltage starting is ideal for applications where full motor torque could tear or damage a product, such as paper or delicate fabric. Learners will study Wye-Delta power distribution, types of voltage circuits, and the operation of an autotransformer reduced voltage starter.

Reduced voltage starting includes a Dual Transformer Station, featuring two control transformers, and a Power Resistor Station, featuring three 25-ohm, 100-watt resistors. This industrial motor control training system uses industrial-quality components that stand up to frequent use and enables learners to practice with real-world components that they will encounter on the job.

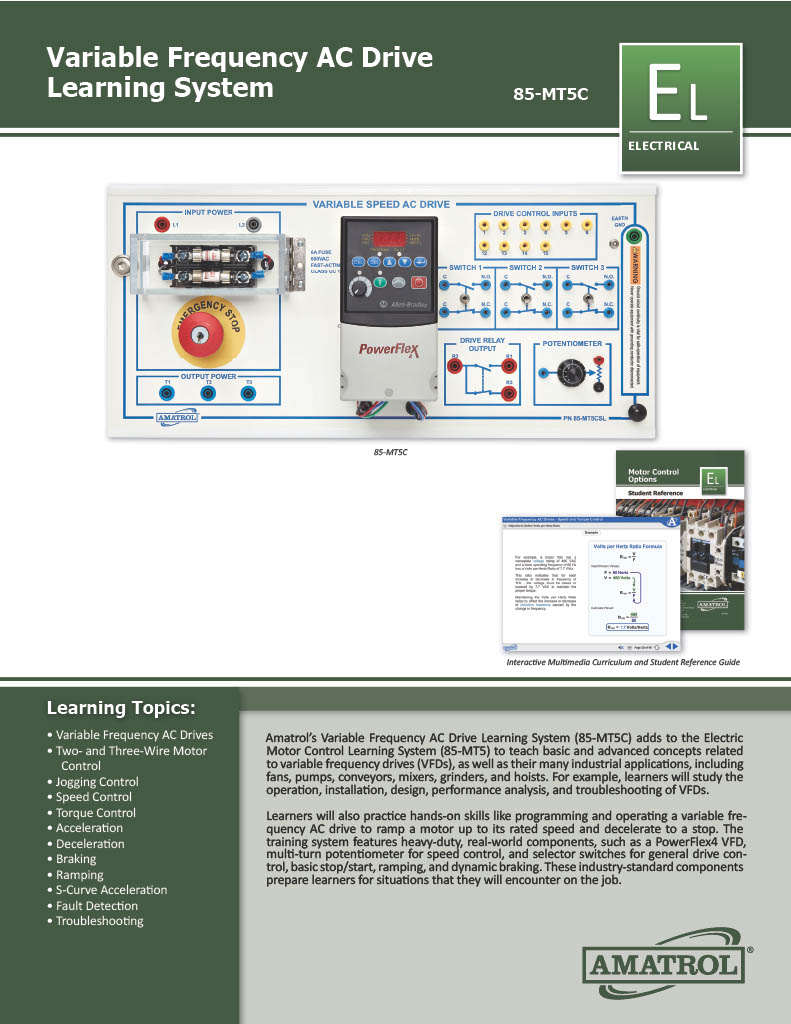

Amatrol’s Variable Frequency AC Drive Learning System, AB PowerFlex (85-MT5C) adds to the Electric Motor Control Learning System (85-MT5) to teach basic and advanced concepts related to variable frequency drives (VFDs), as well as their many industrial applications, including fans, pumps, conveyors, mixers, grinders, and hoists. For example, learners will study the operation, installation, design, performance analysis, and troubleshooting of VFDs.

Learners will also practice hands-on skills like programming and operating a variable frequency AC drive to ramp a motor up to its rated speed and decelerate to a stop. The training system features heavy-duty, real-world components, such as an Allen-Bradley PowerFlex4 VFD, multi-turn potentiometer for speed control, and selector switches for general drive control, basic stop/start, ramping, and dynamic braking. These industry-standard components prepare learners for situations that they will encounter on the job.

Pages

-

Item Number:TFX-CRU-R-1Experience unparalleled realism in medical training with the TacMed CRU-R, a high-fidelity trauma simulator offering lifelike features like active breathing, CPR, central line insertion, and remote-controlled operation. Discover its versatility and mix-and-match capability for comprehensive clinical simulations.

-

Item Number:295-714DAC Worldwide’s Clip Valve Cutaway (295-714) is a sectioned industrial valve sample that allows for valuable classroom training in the operation, construction, and maintenance of industrial clip gate valves.

-

Item Number:950-STCL1Amatrol’s Solar Thermal Troubleshooting – Closed-Loop Learning System (950-STCL1) trains students in solar system operation, programming, and troubleshooting with hands-on equipment and eLearning, covering both pressurized and drainback systems.

-

Item Number:A02B-0158-B110#USFANUC's CNC education simulator is tailor-made for learning, providing cost-effective entry to the cutting-edge FANUC 0i-MODEL F Plus CNC platform. It comes in a compact, portable package that seamlessly fits into any classroom setting. Additionally, with the screen display function software, you can conveniently assume partial control of the simulator via a PC connected through Ethernet.

-

Explore Lincoln Electric's Torchmate CNC plasma cutting tables for education, including the 4410, 4810, and 4510 models. Equip students with hands-on CAD/CAM skills using industry-leading tools and curriculum.

-

The NEW CRX educational package presents a new take on robot training. It features a FANUC CRX-10iA collaborative robot and all the functions required to teach core programming skills.

-

Item Number:T7200Amatrol’s T7200 Combined Refrigeration Installation Learning System teaches hands-on HVACR skills with real-world components and interactive multimedia.

-

Item Number:T7400Amatrol’s T7400 Commercial Refrigeration Learning System teaches students to operate, maintain, and troubleshoot refrigeration systems with real-world components, smart controllers, and FaultPro fault-insertion software.

-

Expand your program’s capabilities with the Compact 1000 and 1000 Pro, precision CNC routers ideal for technical education and light prototyping.

-

The Compact TranSim™ by Acron Aviation is a cost-effective, space-saving commercial truck driving simulator that delivers immersive, high-impact training without putting people or equipment at risk.