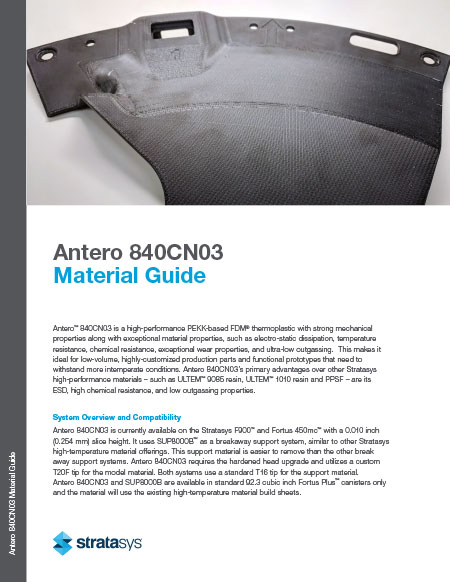

Antero™ 840CN03 is a high-performance PEKK-based FDM® thermoplastic with strong mechanical properties and exceptional material properties, such as electro-static dissipation, temperature resistance, chemical resistance, exceptional wear properties, and ultra-low outgassing. This makes it ideal for low-volume, highly-customized production parts and functional prototypes that must withstand more intemperate conditions. Antero 840CN03’s primary advantages over other Stratasys high-performance materials – such as ULTEM™ 9085 resin, ULTEM™ 1010 resin, and PPSF – are its ESD, high chemical resistance, and low outgassing properties.

System Overview and Compatibility

Antero 840CN03 is available on the Stratasys F900™ and Fortus 450mc™ with a 0.010 inch (0.254 mm) slice height. It uses SUP8000B™ as a breakaway support system, similar to other Stratasys high-temperature material offerings. This support material is easier to remove than the other breakaway support systems. Antero 840CN03 requires the hardened head upgrade and utilizes a custom T20F tip for the model material. Both systems use a standard T16 tip for the support material.

Antero 840CN03 and SUP8000B are available in standard 92.3 cubic inch Fortus Plus™ canisters only, and the material will use the existing high-temperature material build sheets.

Antero™ 800NA is a PEKK-based FDM® thermoplastic. It combines FDM’s design freedom and ease of use with the excellent strength, toughness, and wear-resistant properties of PEKK material.

Antero 800NA exhibits high heat resistance, chemical resistance, low outgassing, and dimensional stability, particularly in large parts.

Appropriate applications include aircraft components exposed to jet fuel, oil, and hydraulic fluid, spacecraft parts that demand low outgassing, and chemical-resistant industrial parts. Using Antero 800NA with FDM technology avoids the waste associated with subtractive manufacturing of high-cost bulk PEKK material.

Antero 800NA is available on Fortus 450mc™ and F900™ 3D Printers and is compatible with breakaway support material SUP8000B™.

ASA (acrylonitrile styrene acrylate) FDM® filament is a broad-use commodity thermoplastic. It is similar to ABS (acrylonitrile butadiene styrene) but exhibits better UV resistance, mechanical properties, and aesthetics than ABS.

ASA suits most general-purpose 3D printing applications involving prototyping, jigs and fixtures, and low-volume production parts. ASA filament is available in the most colors of any FDM material.

Offering a variety of production-grade thermoplastics, FDM® technology creates parts that are highly accurate, tough, and suitable for both functional prototyping and end-use parts. ABS is the most common material used as it boasts good mechanical properties and high name recognition. Compared with ASA, ABS may be more familiar because of its popularity in mass production.

ASA is another popular all-purpose material for jigs and fixtures, manufacturing aids, prototyping and limited-run end-use parts. ASA matches or exceeds the mechanical properties of standard ABS and has greater heat resistance. Moreover, ASA demonstrates exceptional UV stability and, with its matte finish, offers the best aesthetics of any FDM thermoplastic. It’s especially suited for end-use parts in outdoor commercial and infrastructure applications, and its wide array of color options surpasses that of ABS.

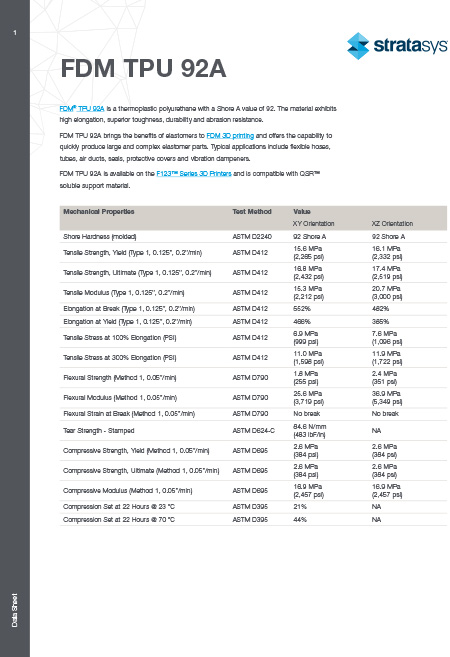

FDM® TPU 92A is a thermoplastic polyurethane with a Shore A value of 92. The material exhibits high elongation, superior toughness, durability, and abrasion resistance.

FDM TPU 92A brings the benefits of elastomers to FDM 3D printing and can quickly produce large and complex elastomer parts. Typical applications include flexible hoses, tubes, air ducts, seals, protective covers, and vibration dampeners.

FDM TPU 92A is available on the F123™ Series 3D Printers and is compatible with QSR™ soluble support material.

Produce Large and Complex Elastomer Parts

Create accurate elastomer parts quickly and efficiently with the ease and reliability of professional FDM 3D printing. The durable elasticity of FDM TPU 92A material makes it a good choice for a variety of applications, including flexible hoses, tubes, air ducts and vibration dampeners.

Kimya PC-FR is a polycarbonate (PC) based material with flame-retardant properties developed specifically for additive manufacturing. It retains the beneficial characteristics of standard polycarbonate such as dimensional stability, high glass transition temperature, and high impact resistance.

Key Attributes

- Flame-resistant material

- Electrical insulator

- Good dimensional stability

- Meets or exceeds the mechanical performance of Stratasys PC material

- Compatible with soluble support

- Meets EN 45545-2 and NFPA 130 standards

- Slice heights: 10

Nylon 12 is a semi-crystalline, FDM® thermoplastic. As with other semi-crystalline materials used in traditional manufacturing processes, special considerations should be implemented to ensure an optimal part is obtained. The information in this document illustrates the following considerations:

- Tip Selection

- Build Modes

- Porosity

- Sacrificial Tower Features

- Build Sheets

- Support Removal

- Annealing

Pages

-

This virtual reality course from Hard Hat VR aims to deliver thorough training on the secure and productive operation of forklifts. The primary objective of this course is to educate workers on the best practices and safety procedures associated with forklift operation.

-

Item Number:FWDSimply set up the simulator controls , install the simulation software (in English or French) on your desktop or laptop PC, and begin! The simulation software puts you at the controls of a typical forwarder equipped with an articulated boom, telescoping extension, and free-swinging grapple attachment. You can even change the viewpoint during the simulation at the touch of a button.

-

Future-proof your robotic welding training with the Fronius TPS/i MIG/MAG system. Modular, intelligent, and optimized for APT/FANUC robotic welding carts. Book a demo today.

-

Item Number:816-PACDAC Worldwide’s Fuse Sample Board (816-PAC) is an introductory hands-on teaching aid, designed to supplement courses in fuse selection and maintenance. It includes samples of twelve (12) industrial-quality fuses for users to learn to identify.

-

Item Number:295-301DAC Worldwide’s Gas Turbine Model (295-301) depicts a detailed to-scale model of a generic gas turbine.

-

Item Number:ABS/2000The trainer allows students to study the absorption of NH3 or CO2 in water, determine the material balance of the gaseous solute, influence of operational parameters on efficiency of the column, thermal balance, packing factor, and more. Educational handbook and technical manual included.

-

Item Number:251DAC Worldwide’s Gate Valve Cutaway (251) features an actual industrial gate valve with the complete internal configuration exposed and seal features and hardware locations retained to provide gate valve maintenance training, as well as show how the valve operates and how it is constructed.

-

Item Number:251KThis Dissectible allows students to disassemble and reassemble a gate valve in order to build competency in understanding how the valve works, the basic components, and routine maintenance.

-

Item Number:205-000DAC Worldwide’s Gear Maintenance Training System (205-000) features a diverse selection of industrial-quality gears, shafts, and bearings that can be used in a variety of configurations. Learners will benefit from convenient hands-on training in gear identification, installation, alignment, and troubleshooting.

-

Item Number:205-PACDAC Worldwide’s Gear Maintenance Training System Plus (205-PAC) features a diverse selection of industrial-quality gears, shafts, and bearings that can be used in a variety of configurations. Learners will benefit from convenient hands-on training in gear identification, installation, alignment, and troubleshooting.