Pignat is a global leader in hands-on training systems for chemical and process engineering, offering robust, transparent units designed to enhance understanding of real-world industrial operations. With a focus on glass-based construction, Pignat’s systems allow learners to observe processes directly—bringing theory to life in both academic and industrial training environments. Trusted by universities, technical institutes, and research centers worldwide, Pignat products support education and experimentation across core disciplines like distillation, absorption, reaction kinetics, heat exchange, filtration, and more.

Pignat’s product range is thoughtfully organized to serve learners from introductory to advanced levels. Mini Units introduce essential principles on a lab scale, ideal for high schools, technical colleges, and undergraduate programs. Larger pilot and industrial-scale units replicate commercial conditions for advanced research and skill development, supporting graduate programs and workforce training initiatives. With transparent operation, integrated instrumentation, and options for manual or automated SCADA control, Pignat systems make it easy to visualize, analyze, and optimize chemical processes.

Explore individual process techniques—like distillation, crystallization, or extraction—or investigate full system behavior through multi-stage continuous plants and reactors. Every Pignat system is engineered for education, research, and innovation in the chemical sciences.

Virtual & Augmented Reality Simulation & Training

FreeRange XR has developed the first fully immersive extended reality (XR) simulation modules to supplement standard training. Learners get to put their training into practice immediately while getting feedback on performance.

Users can take advantage of specialized software packages that bundle vital training modules for specific topic areas. Software and VR headsets are used to deliver the extended reality experience for the learner – these make a great addition to your safety training program! FreeRange XR has developed specialized packages that deliver multiple modules of vital training.

Why is Workplace Safety Training Important?

According to the United States Bureau of Labor Statistics, an employer-reported nonfatal injury or illness occurred at 2.8 cases per 100 workers in 2018. However, it was reported to the Occupational Safety and Health Administration (OSHA) that 5,147 workers died on the job in 2017. In order to protect future workers from serious injury or death, companies have turned to Workplace Safety Training courses to keep their employees safe.

How We Can Help

We work with both educational and industrial partners to provide the training tools for their programs. Career & Technical Education and company training programs use our virtual reality and hands-on systems to allow learners to review safety concepts in a safe environment.

Amatrol’s FaultPro computer-based fault insertion software is the industry’s only electronic troubleshooting training system. FaultPro allows instructors to instantly set and tailor faults to test a student’s weaknesses and turn them into strengths. The troubleshooting skills taught by FaultPro allow students to solve real-world problems they’ll encounter on the job. FaultPro inserts electronic faults safely, protecting both students and equipment from incurring any damage.

FaultPro comes standard with more than two dozen Amatrol training systems spanning seven different technologies.

First Responder Trainees Get State-of-the-Art Training

High schools and colleges with emergency responder simulators can prepare students for careers in the emergency medical field by using industry-leading equipment. From TacMed’s real-life body cast simulators, to Lucas-Nuelle’s HEV/EV first responder trainers, to L3Harris’ fire truck driving simulators students and faculty will be training on some of the most cutting-edge industry equipment.

Dedicated to Serve and Protect

TacMed Solutions is dedicated to improving survivability in crises. They equip, train, and protect all who answer the call - from professionals to active bystanders - with world-class innovative solutions designed to help save lives.

From point of injury throughout the continuum of clinical care; Warfighters, First Responders, and citizens alike, all rely on their extensive tactical field experience and product knowledge to supply intuitive solutions. They develop and manufacture customized emergency response technology, advanced simulation and training aids, and personal protective gear to effectively manage a spectrum of hostile environments and injuries.

HVAC/R Skills are Vital for Industrial and Residential Applications

Heating, ventilation, air conditioning, and refrigeration (HVAC/R) skills, including thermal, geothermal, and steam power, are a unique skill set that demands a firm understanding of the principles involved. Amatrol's HVAC/R learning systems start with the basics, such as phase change, and continue into more advanced concepts, such as enthalpy and the laws of thermodynamics. These systems teach hands-on skills related to pressure measurements, preventative maintenance, and troubleshooting.

Amatrol’s HVAC Training Program combines world-class simulators featuring industry-standard components with an unrivaled online eLearning HVAC curriculum in areas such as electrical, fluid power, mechanical, electronics and many more!

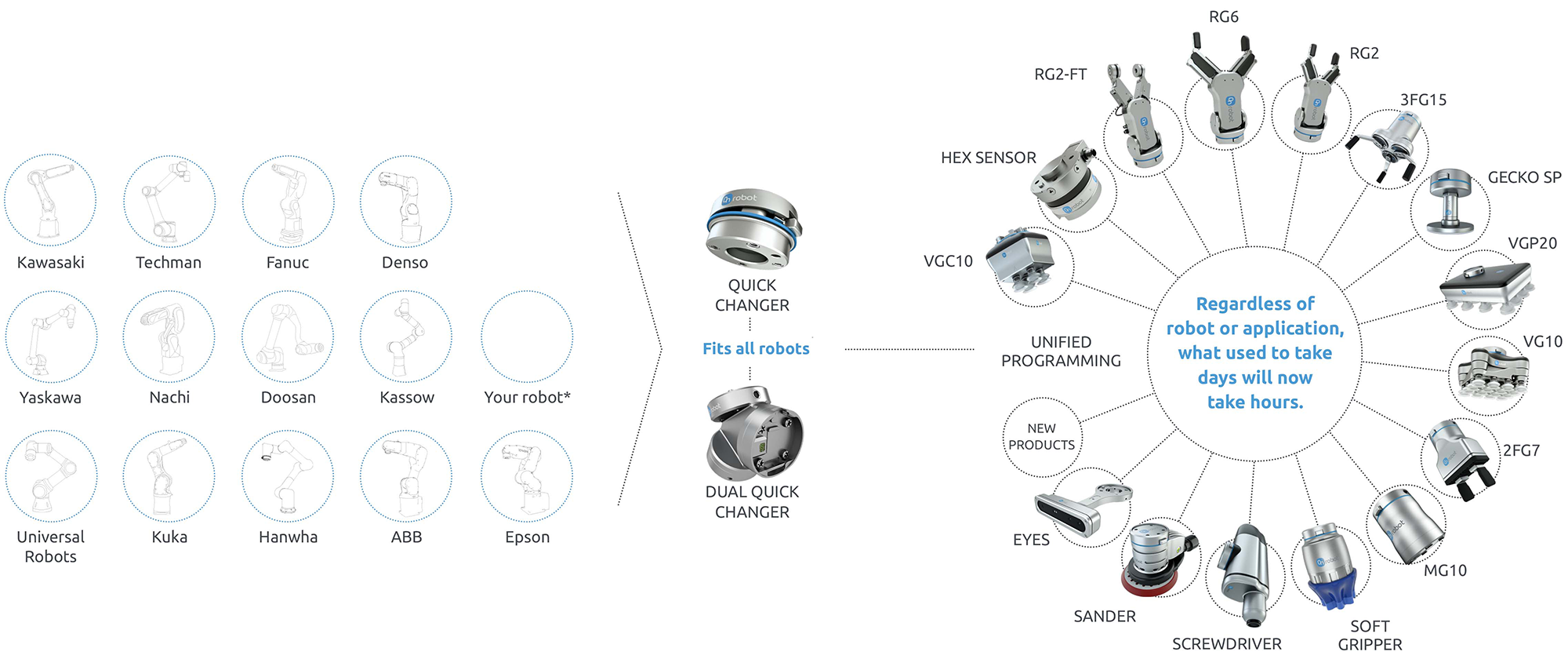

OnRobot offers the industry’s broadest range of end-of-arm tooling and software solutions for collaborative applications. Automate your processes quickly and efficiently with OnRobot’s Plug-and-Produce grippers, sensors, vision and the software that drives them.

Collaborative Application

Collaborative robots have leveled the playing field for small and medium-sized enterprises (SMEs), and as robots become easier to buy and implement, the tooling has become the vital element in adapting collaborative and light industrial robots for an extensive range of applications.

Now you can equip your robots with a wide variety of “Plug-and-Produce” End-Effectors for your collaborative and light Industrial robot applications. Choose between various combinations from OnRobot, making it quick and easy to customize your robot to ever-changing applications in your lab.

You can also add the OnRobot Compute Box and I/O tester demo board to your end-effectors for lab simulation, allowing students to carry out proof of concept exercises without needing to take the robot off-task or tie up a workstation being used!

One-Stop Shop

Get started maximizing the utilization of your robots with OnRobot’s grippers, sensors, and tool changers. These flexible automation tools are compatible with most major robot brands, saving you time and money with the easy and fast deployment of collaborative applications.

OnRobot’s smart solutions enable robots to handle adaptive, high-precision applications such as:

- Machine Tending – CNC, IMM, Press

- Material Handling – Transferring, Sorting, Packaging, Palletizing

- Material Removal – Deburring, Sanding, Polishing, Buffing, Drilling, and Milling

- Quality – Measuring, Testing, and Inspecting

- Assembly – Inserting, Mounting, Positioning, Screwdriving, and Nutdriving

Plus whatever else you can imagine!

One Stop Shop for Collaborative Applications

OnRobot products open new possibilities for automating tasks that you never thought possible. Our cutting-edge gripping and sensing systems for industrial automation let you easily design truly collaborative applications that enable your workforce to work side-by-side with collaborative robots on assembly, surface finishing, pick and place, machine tending or testing.

OnRobot products open new possibilities for automating tasks that you never thought possible. Our cutting-edge gripping and sensing systems for industrial automation let you easily design truly collaborative applications that enable your workforce to work side-by-side with collaborative robots on assembly, surface finishing, pick and place, machine tending or testing.

Any robot you choose. One OnRobot system.

Save integration time and simplify deployment with our complete solution.

*If your robot arm is not represented above, contact us for more information on compatibility on other robot brands.

All products listed were developed in partnership with the FANUC America Education Group and are sold exclusively through the FANUC Education Reseller Network . They carry the industry training curriculum of key manufacturers like FANUC America , Rockwell Automation , and Miller Welding .

High School Training: Years ago, we founded a state-of-the-art high school training center where we opened our doors to high school students from surrounding schools to learn the nuts and bolts of manufacturing. We lead them through coursework and hands-on learning designed to open their eyes to the opportunities they have in industry after school.

Apprenticeship Program: Students who graduate from these programs must enroll in an apprenticeship program to continue employment, where they go through a two- or four-year program, fully paid, working during the day and continuing school at a community college at night. This has proven to be a phenomenal approach to education, developed over time based on the need for workforce development. The key to this is the partnership that has come between industry and education. We believe this partnership is vital to changing industry and solving the workforce development problem as America moves forward.

It was through this partnership with education, as well as our relationship with FANUC Education, that we realized the gap in the market for trainers and curriculum. Colleges are using equipment to teach industrial systems that doesn’t match what a student will see upon graduation. Students aren’t able to get exposed to real-world industrial equipment in school, because it doesn’t exist. What does exist is watered-down trainers with and curriculum. America needs an industry-level curriculum, taught on industry-level equipment so that students are prepared for the workforce when they leave the classroom.

Our trainers were developed in partnership with FANUC America education, and are sold exclusively through the FANUC Education Reseller Network. They carry the industry training curriculum of key manufacturers like FANUC America, Rockwell Automation, and Miller Welding. These partnerships are critical to maintaining high-caliber trainers that model industry standards.