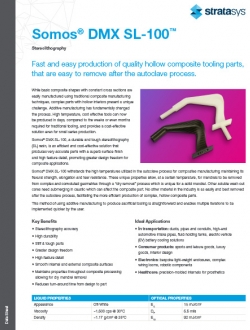

Somos® DMX SL™ 100

Breaking the mold in speed, efficiency, and design freedom.

Somos® DMX SL™-100 is a durable and tough stereolithography material that enables production of complex, hollow composite parts in days thanks to a unique and cost-effective ‘dry removal’ process - and all with no compromise on quality and aesthetics.

The ‘dry removal’ process enables mandrels to be removed from complex, convoluted geometries after the autoclave without the need for submersion in caustic (which can affect the composite part). Somos® DMX SL™-100 produces accurate parts with a superb surface finish and outstanding feature detail. Somos® DMX-SL-100 withstands the extreme temperatures of the autoclave process utilized in composites manufacturing, maintaining its flexural strength, elongation and tear resistance.

As a result, manufacturers have more design freedom to create high-temperature, cost-effective tools in days rather than weeks or sometimes even months.

Key Features

- Accuracy

- Extreme durability

- Greater design freedom

- High feature detail and smooth finish

- Faster part design

Applications

- Composite tooling

- Prototyping

- Tooling

- Healthcare: precision-molded internals for prosthetics

- Electronics: bespoke light-weight enclosures, complex wiring looms, robotic components Automotive & transportation: ducts, pipes and conduits, high-end automotive intake pipes, fluid-holding tanks, electric vehicle (EV) battery cooling solutions