Advanced Manufacturing CERT M20 Cell

Introducing, the AM-CERT, a FANUC CERT Cell specifically built for Advanced Manufacturing.

FANUC America and APT Manufacturing Solutions partnered to develop educational “cells” for Advanced Manufacturing CERT training.

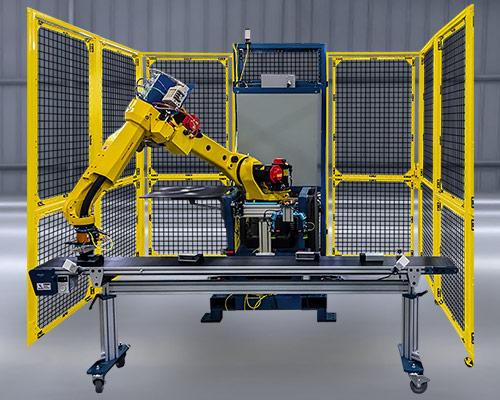

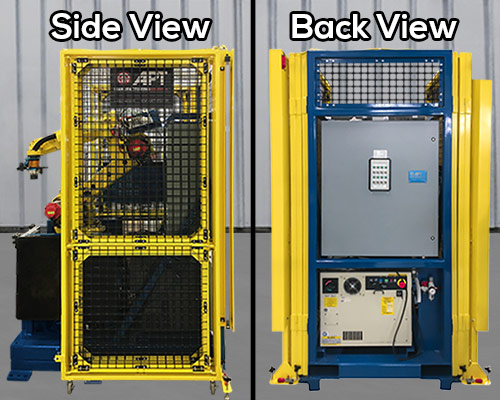

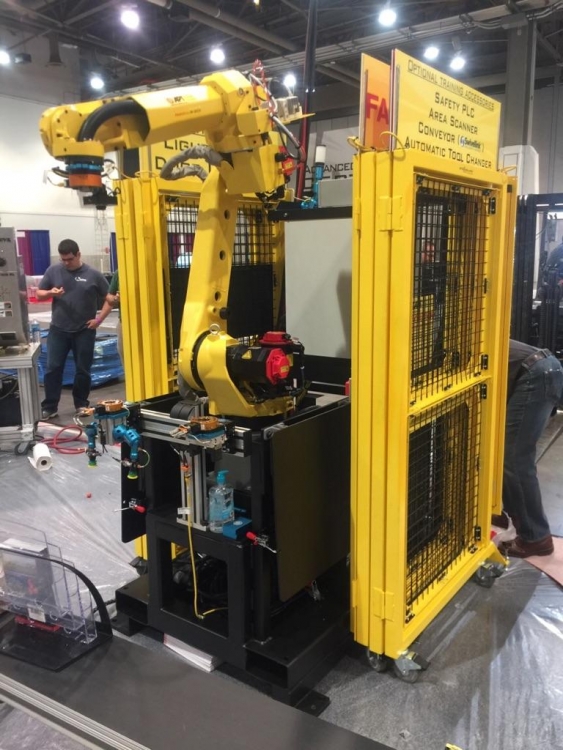

The APT AM-CERT Cell utilizes a FANUC M10 or M20 robot with communication to a PLC, multiple End of Arm Tooling options, custom folding fencing, and safety training features built into a single system that is portable using a pallet jack or forklift. To accommodate the limited space in education environments, this cell is designed to expand to a 10’ x 10’ work cell giving adequate area for conveyors, palletizing, or pick and place, and when you are done just fold up the guarding to have a cell that is now only 54” wide by 72” deep.

The APT AM-CERT is a full-featured large robot cell using the full-sized FANUC R30iB robot controller platform, fully integrated to Rockwell Automation CompactLogix PLC using Studio 5000 based programming and a Rockwell PanelView Plus 10” interface touch screen. This cell can teach PLC programming and advanced robot material handling in one self-contained, transportable cell. Advanced safety can be explained by use of safety interlock switches and light curtain or area scanner fully integrated into the robot and P

LC safety circuit. The cell is ready for the optional conveyor to supply parts to the robot or away from the robot to outside the safety fencing.Students will gain hands-on experience with standard industrial components they are most likely to see in real manufacturing environments. Learn robot program calls from a PLC based on decisions. Test I/O, motor operation, safety inputs, and vision-guided robotics.

Curriculum

FANUC Robotics Courses:

- Handling Tool Operation and Programming

- Handling PRO

- iR Vision 2D

- Advanced TPP

- DCS

Rockwell Automation Courses:

- CCP 183: Ethernet / IP Configuration and Troubleshooting

- CCP 146: Logix 5000 System Fundamentals

- CCP153: Maintenance and Troubleshooting

- CCP 151: Basic Ladder Logic Programming

- CCP 143: Ladder Logic Project Development

- CCV 204-A: FactoryTalk View ME & PanelView Plus Programming

- INA 201: Industrial Network Architecture Foundation

- INA 202: Industrial Network Architecture Intermediate

- CCP 251: Advanced Logix 5000 Programmer

- CCP 154: Studio Logix Designer Level 4 ST & SFC

- SAF LOG 104: Guard Logix (and Banner) application development

APT Integration Courses:

- Schematic Reading Fundamentals

- Introduction to Integration – Labs and Exercises

- Intermediate Concepts:

Maintenance and Troubleshooting of Industrial Equipment - Introduction to Industrial Automation and Integration

- Basic Integration Labs: PLC, HMI, Robot, Ancillary Components

- Introduction to Safety Systems

- Safety Systems, Standards Design, and Application

Career Paths and Certifications

Career Paths:

- FANUC Robot Operator – Material Handling

- PLC/Controls Operator

- FANUC Robot Technician

- Maintenance Technician

- PLC/Controls Technician

- Industrial Controls Integrator

NOCTI Certifications:

- FCR-01 (FANUC Certified Operator 1) – Written

- FCR-02 (FANUC Certified Operator 2) – Performance

- FCR-T1 (FANUC Certified Robot Technician 2)

Software

Material Handling (MH) CERT School Comprehensive Educational Package

- (25) online seat to take Robot Operations web course

- (25) online seat to take HandlingTool or ArcTool Operation and Programming web course

- (25) online seat to take HandlingPRO or WeldPRO web course

- (25) ROBOGUIDE Simulation Software license

Material Handling (MH) CERT Instructor Training and Tool Kit

- (1) online seat to take CERT Cart Safety Features web course

- (1) online seat to take Robot Operations web course

- (1) online seat to take HandlingTool or ArcTool Operation and Programming web course

- (1) online seat to take HandlingPRO or WeldPRO web course

- (1) seat to take a live HandlingTool or ArcTool Operation and Programming class at a FANUC facility

- (1) ROBOGUIDE Simulation Software license

- (1) FANUC Robot Operations Manual

- (1) FANUC HandlingTool or ArcTool Operations and Programming Manual

- (1) FANUC HandlingPRO (ROBOGUIDE Simulation) Manual

*FANUC Education Grant available for new Educational Institutes. Work with reseller to confirm details.

Rockwell Software Package

- (1) EDU Toolkit Bundle with

- (1) 1-year subscription

- (1) Studio 5000 Logix Designer

- (1) Studio 5000 View Designer

Plus over 100 more!

Rockwell e-Learning Package

- CompactLogix 5000 System Fundamentals

- Basic Ladder Logic Project Development

- Plus many more

| Product # | Description |

| AM CERT-10 | Material Handling CERT Cell with M10 Robot |

| AMCERT-20 | Material Handling CERT Cell with M20 Robot |

| Option 1 | Swivellink Conveyor |

| Option 2 | Area Scanner 270 degree protection |

| Option 3 | Automatic Tool Change |

| Option 4 | Safety PLC Option |

| Option 5 | Transformer 208, 220, or 240V 3 Phase power |