Machine Tending Education Cell

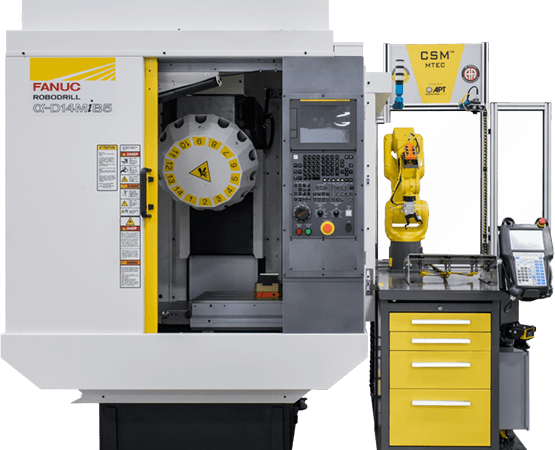

The MTEC is an advanced manufacturing, CNC Load/Unload system; complete with curriculum and training for your students to integrate and program a CNC and Robot.

The Machine Tending Education Cell is designed to showcase real-world applications of robot tended CNC machinery. A machine tender is designed to take away the mundane load/unload tasks of an operator in a normal CNC machine shop. It has been designed to easily integrate with small to medium-sized CNC machinery. Students will teach the robot pick and place locations and the air blowoff path. All communication input/output is pre-configured and ready for integration to the CNC machine using M codes in the CNC program. Note that the CNC machine may require upgrades for the communication to the robot.

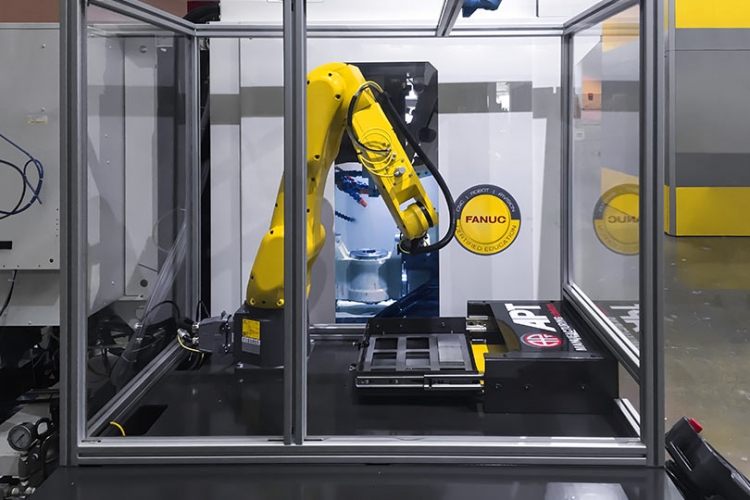

Part blank location is done with a template-based part locator. The system above includes a template with cutouts for the standard NIMS mill block and included aluminum parts blanks. The template is made from 12 ga 304 stainless steel for low profile part locating and long life. New templates are easy to machine the appropriate part locating shapes into for future project-based machining operations. The robot is set up for the template by row count, column count, row pitch, and column pitch. The first pick and place point is the only position that the robot needs to be taught, all other positions are driven from the row and column count and pitch in a standard grid-type pattern. Dimensional drawing is also provided of the template blank for creating more custom templates as the end-user sees fit.

Although this equipment is considered level 3 advanced manufacturing, it can still be used to teach level 1 and level 2 concepts, making it a versatile and budget-friendly purchase for any school looking to extend the depth of their FANUC training.

Our education equipment is not a “trainer”, it is the same advanced machinery a student would encounter upon graduation. The MTEC can be used to teach CNC programming concepts, integration of a robot and CNC, robot programming and tool handling, and maintenance troubleshooting. Our Project-Based Curriculum will also teach students vital post-graduation skills like problem-solving, reasoning, and critical thinking.

MTEC Features

- Qualifies for FANUC educational CERT program (LR Mate only)

- Integrated with FANUC Robot and ROBODRILL

- FANUC ROBODRILL or Levil CNC options

- Optional iRVision

Training Areas: Robot, iRVision 2D

Training Levels: I, II

Give your students the opportunity to learn real world advanced automation integration with the Machine Tending Education Cell.

What can I do with an MTEC-SIM?

Curriculum

FANUC Robotics Courses:

- Handling Tool Operation and Programming

- Handling PRO

- iR Vision 2D

- Advanced TPP

- DCS

- Robodrill Maintenance

CNC Concepts Courses:

- Machining, Programming, Setup, and Operation

- Turning, Programming, Setup, and Operation

APT Integration Courses:

- Intermediate Concepts: Maintenance and Troubleshooting of Industrial Equipment

- Introduction to Industrial Automation and Integration

- Basic Integration Labs: PLC, HMI, Robot, Ancillary Components

- Robot to CNC: Integration Fundamentals and Labs

- Safety Systems, Standard Design, and Application

Career Paths and Certifications

Career Paths:

- FANUC Robot Operator – Material Handling

- FANUC Robot Technician

- CNC Operator

- CNC Machine Technician

- Maintenance Technician

- PLC/Controls Technician

- Industrial Controls Integrator

- Robot Integrator

NOCTI Certifications:

- FCR-01 (FANUC Certified Operator 1) – Written

- FCR-02 (FANUC Certified Operator 2) – Performance

- FCR-T1 (FANUC Certified Robot Technician 2)

NIMS Certifications:

- CNC Mill Programming Setup and Operation

- CNC Mill Operations

Software

Material Handling (MH) CERT Instructor Training and Tool Kit

- (1) online seat to take CERT Cart Safety Features web course

- (1) online seat to take Robot Operations web course

- (1) online seat to take HandlingTool or ArcTool Operation and Programming web course

- (1) online seat to take HandlingPRO or WeldPRO web course

- (1) seat to take a live HandlingTool or ArcTool Operation and Programming class at a FANUC facility

- (1) ROBOGUIDE Simulation Software license

- (1) FANUC Robot Operations Manual

- (1) FANUC HandlingTool or ArcTool Operations and Programming Manual

- (1) FANUC HandlingPRO (ROBOGUIDE Simulation) Manual

Material Handling (MH) CERT School Comprehensive Educational Package

- (25) online seat to take Robot Operations web course

- (25) online seat to take HandlingTool or ArcTool Operation and Programming web course

- (25) online seat to take HandlingPRO or WeldPRO web course

- (25) ROBOGUIDE Simulation Software license

*FANUC Education Grant available for new Educational Institutes. Work with reseller to confirm details.

Features

- Communication between Robot and CNC

- Robot pick area guarded 3 sides on the cart

- Safety interlocked access door to robot work area

- Three color beacon operation indicator light

- “Safe Load” parts blank drawer with part locating template for NIMS block or dual conveyor in/out for parts blanks

- Single 2 jaw EOAT for NIMS mill block (3/4” x 2-1/2” x 3-1/2” aluminum, 50 pcs included)

Features

- Modular Robot Cart

- Welded Steel Construction

- Fits through standard doorway

- Fold up worktable for laptop, test book, etc.

- Swivel casters with brakes and rotation lock

- FANUC R30iB Plus Robot Controller

- FANUC LR Mate 200iD/7L Long Arm 6 axis robot

- 2D iRVision Optional

FANUC’s new R-30iB Plus Robot Controllers feature the new iPendant with enhanced screen resolution and processing capability. The new user interface, iHMI, can display guides for setup and programming, as well as tutorials from the main home page which has a design common to FANUC CNCs, enabling easier use of robots. Using the programming guide, even first-time robot users can create a program for a simple handling task and execute it in just 30 minutes! Easier usage also improves efficiency by facilitating system setup and maintenance.

FANUC’s CNC certification is an industry certification We offer many options for the student to obtain this certification. The FANUC Robodrill and simulators along with any CNC machine that has the FANUC controls. FANUC offers the school instructor FANUC training, they can also use the FANUC approved curriculum.

There is a letter issued to the student upon completion to say they are certified. For the instructor there is a certificate template that can use to issue the student certificates.

- Tabletop machine

- 120V power

- FANUC robot load/unload

- Qualifies for FANUC CNC Cert

- Qualifies for FANUC Robot Cert

Additional Items:

CNC Mill Work Holding Kit Includes:

- Pneumatic two jaw, self-centering, vise. Overall footprint of the vise is 6” X 6” and can be attached to the CNC mill table using T-Nuts.

- Set of vise jaws will be cut to hold the NIMS mill block blank included with the MTEC.

- Additional set of unmodified soft jaws that the end user can cut to suit their needs.

- The vise is activated by a standard 24 VDC pneumatic valve supplied with the vise kit.

- The kit will come with the required fittings for the vise and valve, and a length of ¼’ OD air tubing to be routed from the CNC to the activation valve.

Starter Kit for BT30 Robodrills Machines (Includes 1 each):

- BT30 taper shank holder with ER20 collet nut

- C Style BT30 Taper 45° Retention knob

- 3/8″ ER20 ER Collet

- ER20 Collet Nut Wrench

- BT30 Tightening Fixture

Options:

- iRVision, Fenced or Fenceless, Toolbox, Air compressor