Josh Evans, Applications Engineer and Head of Learning, goes back to basics to help us understand the value to manufacturers of investing in filtration and fume extraction.

In this episode, we're joined by Josh Evans, Applications Engineer at BOFA with specialist knowledge of laser-generated emissions. Josh helps to explain the vital role that fume extraction plays in keeping FMCG production lines moving.

In this episode, we're joined by Nigel Bedford, Technical Development Manager at BOFA. Nigel guides us through the evolving world of 3D printing and additive manufacturing and explains how BOFA keeps pace with the new materials being used.

In this episode, we're joined by Geoff Hamilton, International Sales Manager, and Dawn Hartung, Strategic Account Manager at BOFA. Throughout this episode, they explore the latest innovations in the print industry and the need for filtration to help maintain a healthy printing environment and product quality.

In this episode, we're speaking with Graham Mattok, UK and Ireland Sales Manager. Graham explores how automation in electronics manufacturing is helping to enable the era of Internet of Things connectivity, from consumable ‘wearables’ to autonomous driving.

The ‘best in class’ high-performance AD Oracle has now been further enhanced with BOFA’s Intelligent Operating System (iQ), combining a range of unique features into one compact unit.

The Intelligent Operating System (iQ) performs at two distinct levels. Operators benefit from the ease of operation and clarity of real-time information, the system also provides a cache of analytical data, enabling users to download performance and operating parameters for evaluation purposes.

The iQ system takes performance and safety parameters to a new level and helps keep maintenance downtime and ownership costs to a minimum.

In this episode, we're speaking with Geoff Sagar, Product Manager at BOFA with specialist knowledge of laser processes, particularly in packaging and traceability.

Geoff explains how lasers play an important role in creating the markings and batch codes we see on so many products and how filtration technology contributes to effective traceability.

In this episode, we're speaking with Shravya Nahar Product Manager at BOFA with specialist knowledge of additive manufacturing and extraction technology.

Shravya discusses the important interaction between temperature control and fume and particle extraction in additive manufacturing and how this need for extraction can be achieved while maintaining optimal chamber conditions.

Dawn Hartung, Strategic Account Manager at BOFA Americas, is joined by Jay Roberts, Product Manager for UV Printers at leading print technology company Roland to discuss some of the innovations that are helping to contribute to a more sustainable future in printing.

The refreshed BOFA 3D PrintPRO 4 provides a premium fume extraction solution for high-performing 3D printers. With a special blend of chemical adsorbents and high-efficiency particulate filter (HEPA), the extractor helps to filter emissions from 3D printing processes.

Pages

-

Item Number:T7082Amatrol’s Air Conditioning/Heat Pump Operations Learning System (T7082) features industry-standard heating and cooling components that form a working heat pump trainer, ac trainer and refrigeration system.

-

Item Number:T7082AAmatrol’s Air Conditioning / Heat Pump Troubleshooting Trainer (T7082A) teaches valuable HVAC troubleshooting skills on a hands-on learning system that performs heat pump, air conditioning and refrigeration operation.

-

Amatrol’s FaultPro computer-based fault insertion software is the industry’s only electronic troubleshooting training system. FaultPro allows instructors to instantly set and tailor faults to test a student’s weaknesses and turn them into strengths.

-

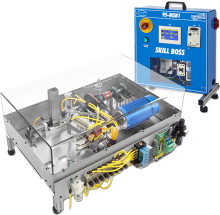

Item Number:95-MSB1Amatrol's Skill Boss Manufacturing is a hands-on training and assessment tool for CPT+ certification that meets MSSC standards easily integrates into manufacturing programs.

-

Train future technicians with Amatrol’s Tabletop Smart Factory and Cobot-Integrated Mechatronics systems—hands-on, compact training with real industrial components, Rockwell Automation integration, and FANUC CRX collaborative robotics.

-

Each Advanced Manufacturing topic incorporates the skill development needed for modern industry. From operation to complex troubleshooting, Amatrol’s learning systems deliver job-ready skills.

-

Item Number:T7045Amatrol’s Basic Refrigeration training system (T7045) offers hands-on learning of a working refrigeration system in a compact tabletop unit.

-

Item Number:T7200Amatrol’s Combined Refrigeration Installation Learning System (T7200), an ideal training tool for HVAC/R technicians, offers a comprehensive hands-on workstation and interactive multimedia curriculum to teach installing electrical and mechanical refrigeration/air conditioning components in residential or light commercial applications.

-

Item Number:T7083Amatrol's Environmental Applications Learning System (T7083), an expansion for the Air Conditioning / Heat Pump Operations Learning System (T7082) or the Troubleshooting Learning System (T7082A), is a model of a house complete with insulation, siding, shingles, and a window.

-

Item Number:CRX 5iA | CRX-10iA | CRX-10iA/L | CRX 20iA/L | CRX 25iAExperience the all-new CRX Series, FANUC's latest collaborative robot designed to make installation and programming your cobots easier than ever before.