At Diboll High School, Career and Technical Education (CTE) is more than just a class—it's a career-launching experience. Students gain real-world skills in engineering and manufacturing, ensuring they are ready for the jobs of tomorrow.

What Makes This Program Unique?

- Amatrol Training System – Industry-standard equipment for hands-on learning.

- FANUC Fenceless Cart – Safe, collaborative robotics training for automation careers

- SACA Certifications – Helping students gain industry-recognized credentials.

- Stratasys 3D Printing – Advanced additive manufacturing technology.

Experience These Innovations Firsthand! We are committed to equipping educators with the best training solutions. Ready to see these technologies in action? Schedule a visit to our Solutions Center and explore hands-on training options for your students.

Levil Control Options for 5-Axis Mill and Mill-Turn

Experience unmatched performance, precision, and control with the FANUC CNC Series 31i-B5. This flyer provides a detailed overview of FANUC’s high-performance CNC system, designed to support even the most demanding machining operations.

Key Features Include:

- Up to 96 axes, 24 spindle axes, and 15 paths: Handle highly complex machining operations with ease.

- Integrated FANUC Dual Check Safety: Maximize operator safety and machine protection during every cycle.

- 3D Interference Check: Prevent collisions and downtime through real-time monitoring and collision control.

- High-Speed Smooth Tool Center Point Compensation: Ensure superior accuracy and finish on intricate parts.

- Integrated High-Speed PMC: Increase efficiency and cycle performance with faster processing.

- Preventive Maintenance Functions: Extend machine life with smart, built-in maintenance tracking.

- MANUAL GUIDE i: Simplify CNC programming with intuitive, conversational controls.

- Dynamic Compensation Functions: Maintain peak accuracy and control with real-time adjustments.

- Learning Control / High-Speed Cycle Machining: Minimize machining times while maintaining quality.

- Simultaneous 5-Axis Machining: Execute advanced geometries and tight tolerances with ease.

- Ultra High-Speed Processors & CNC Internal Bus: Optimize data handling and reduce latency.

- Optical Fiber Communication: Accelerate data transfer for smoother CNC system performance.

Download the brochure now to explore how the FANUC CNC Series 31i-B5 can enhance your shop floor or training environment.

Need help integrating FANUC controls into your curriculum or facility? Contact our team to learn more about automation and CNC training solutions.

What Makes the EDU MiLL Ideal for Classrooms?

Designed with education in mind, the EDU MiLL is easy to use and built to inspire. Its intuitive interface allows students of all levels—from beginners to aspiring engineers—to bring their ideas to life. Whether they’re 3D printing prototypes or milling precision parts, students gain hands-on experience with real industrial processes.

- Simple Operation: Students can confidently operate the EDU MiLL with minimal training.

- Project-Based Learning: Students take ownership of their learning by designing and fabricating their own projects.

- Material Exploration: The ability to work with various materials introduces students to real-world manufacturing challenges and opportunities.

- Future-Ready Skills: Exposure to 3D printing and CNC gives students a head start for careers in engineering, industrial design, and advanced manufacturing.

Creating Opportunities That Matter

For many students, machines like the EDU MiLL are their first exposure to the technologies driving modern industry. Thanks to this hands-on experience, they gain an understanding of real-world production challenges—learning not just how to design and create, but how to solve problems that arise during experimentation.

This foundation prepares them for success in college and beyond, where they can focus on refining solutions instead of learning everything from scratch.

Supporting the Next Generation of Innovators

Programs like the one at Treasure Coast High School wouldn't be possible without support from industry partners and organizations dedicated to advancing STEM and CTE education. Tools like the EDU MiLL don’t just teach—they transform classrooms into innovation labs that increase student engagement, spark creativity, and help young learners see the real-world impact of their education.

Want to bring advanced manufacturing into your classroom? Contact Tech-Labs today to explore EDU MiLL packages and classroom integration support.

Download the Levil Control Options Brochure

Enhance your CNC milling capabilities with the FANUC CNC Series 0i-MF integrated into Levil Technology's control systems. Discover a full suite of features designed to improve precision, optimize workflow, and deliver superior machining results.

Key Programming & Control Features:

- Helical Interpolation: Perform complex operations with precision and ease.

- Set-Up Guidance: Simplify machine setup with intuitive prompts.

- Jerk Control: Reduce mechanical stress and enhance surface finish.

- 3-D Manual Feed: Precise control in three axes for accurate alignment.

- Cutter Radius Compensation: Automatically adjust for cutter radius deviations.

- G54-G59 + 48 Work Offsets: Manage multiple work coordinates effortlessly.

- Polar Coordinate Command: Streamline circular and angular programming tasks.

- Tool Life Management: Monitor and maximize tool usage for cost savings.

- Scaling: Easily adjust program size for different workpiece requirements.

Advanced Machining Features:

- Tilted Working Plane: Machine angled surfaces with high precision.

- Nano-Smoothing: Achieve ultra-smooth finishes and exceptional accuracy.

- Program Restart: Resume operations mid-program with minimal downtime.

- 32-Character Program Names: Improve file organization and identification.

- Small-Hole Peck Drilling: Enhanced performance for delicate drill operations.

- Threading Cycle: Simplify internal and external threading processes.

- 400 Tool Offset Pairs: Store more tools and streamline tool management.

- Tool Length Measurement: Automate tool calibration for accurate machining.

Ready to elevate your CNC operations? Click below to download the full brochure and explore everything the FANUC 0i-MF control system has to offer with Levil CNC Milling Machines.

Need help integrating FANUC controls into your curriculum or facility? Contact our team to learn more about automation and CNC training solutions.

Download the Levil Control Options Brochure for CNC Turning

Boost productivity and precision in your turning operations with the FANUC CNC Series 0i-TF, integrated seamlessly with Levil Technology's advanced control systems. This brochure details powerful features that simplify programming, extend tool life, and deliver exceptional machining accuracy.

Key Turning Control Features:

- Threading Retract: Improve threading accuracy and efficiency.

- Arbitrary Speed Threading & Thread Repair: Perform threads at varying speeds and repair damaged threads with ease.

- Balanced Cut: Achieve smoother, vibration-free cutting operations.

- Dual-Path Synchronization: Coordinate dual-path lathes for optimized throughput.

- Tool-Nose Radius Compensation: Maintain dimensional accuracy automatically.

- Multiple Repetitive Cycles: Streamline complex programs with ease.

- High-Speed Rigid Tapping: Ensure precision with faster tapping operations.

- Standard, Multi-Lead & Variable Lead Threading Cycles: Select the threading cycle that best fits your needs.

Additional Advanced Features:

- Polar Coordinate Interpolation: For C-axis, Y-axis, and live tools with cutter compensation.

- Lathe G-code Systems A/B/C: Enhance flexibility and compatibility.

- Chamfering / Corner R: Simplify edge finishing operations.

- Programmable Data Input: Save time by inputting data directly.

- Direct Drawing Dimension Programming: Easily translate drawings into G-code.

- Threading Cycle: Built-in support for threading operations.

- Polar Coordinate Command: Execute polar commands efficiently.

- Tool Life Management: Extend tool life and reduce downtime.

- Tool Length Measurement: Automatic tool length calibration ensures accuracy.

- Helical Interpolation: Perform complex operations effortlessly.

- Polygon Turning: Create multi-sided profiles with precision.

- High-Speed Skip for Probing: Accelerate probing cycles and save machine time.

Ready to take your CNC turning operations to the next level? Click below to download the full brochure and explore the unmatched features of the FANUC 0i-TF controller integrated with Levil turning machines.

Need help integrating FANUC controls into your curriculum or facility? Contact our team to learn more about automation and CNC training solutions.

Precision Performance in a Small Footprint

This video showcases the impressive capabilities of the Levil Technology LMV-400, a compact yet powerful CNC milling machine engineered for high-precision 3-axis machining — with an optional upgrade to a 4th axis. Whether you're in a small shop, a school lab, or an advanced training center, the LMV-400 is designed to deliver exceptional results without sacrificing valuable space.

Who Is This Machine For?

- Technical education programs looking for real-world machining experience

- Manufacturing labs ready to upgrade their prototyping or small-batch production capabilities

- Training centers looking to integrate CNC machining and robotics into a single workflow

Date: Wednesday, October 15, 2025

Location: The Ranch Events Complex

Date: Wednesday, December 10 to Saturday, December 13, 2025

Location: Gaylord Opryland Resort & Convention Center in Nashville, Tennessee

Prepare students for the rapidly growing world of electric vehicles with the LJ Create Electric Vehicle Charging Stations Panel Trainer. This hands-on system allows learners to safely investigate how EV charging stations operate, communicate, and respond to faults—delivering authentic and immersive training experiences for technical education programs.

- AC & DC Charging Modes: Teach the differences between single-phase and three-phase AC charging and explore high-speed DC charging.

- Vehicle Communication Signals: Students observe and analyze CAN-based signals between the charger and the vehicle, learning how safety interlocks and operational commands are transmitted.

- Real-Time LCD Monitoring: A built-in touchscreen allows students to configure scenarios, monitor battery state of charge, temperature, energy cost, and power flow in real-time.

- Multi-Panel Integration: Compatible with LJ Create’s EV Systems and EV Batteries panels for expanded training scenarios and system interaction.

With 16 built-in fault options and a lockable fault insertion panel, instructors can simulate real-world problems across the charging station and in-car charging components. Students use multimeters, oscilloscopes, and critical thinking to diagnose faults, making it an excellent platform for authentic assessment and technician readiness.

- Onboard DC Charging

- Onboard AC Charging

- Charging Disconnect / Reset Simulation

- DC Charging with Multi-Panel Connection

- AC Charging with Multi-Panel Connection

- 240V 3-phase input simulating grid supply

- Switchable AC/DC charging operation

- Battery temperature and state-of-charge adjustment

- Customizable for different geographic regions

- Instructor control via passcode-protected fault panel

Ideal for high schools, community colleges, technical institutes, and workforce development programs preparing students for careers in EV technology, automotive repair, and renewable energy systems.

Whether you're setting up a new EV lab or expanding your current automotive training program, the LJ Create Electric Vehicle Charging Stations Panel Trainer delivers everything you need to provide relevant, hands-on education.

Contact us today to request a quote, schedule a demo, or speak with a product expert.

FANUC Certified Education Training Solutions

FANUC’s Certified Education Robot Training (CERT) program offers educational institutions and workforce training centers industry-standard robotics and CNC solutions. These systems are designed to prepare students and incumbent workers for high-paying careers in automation, manufacturing, and advanced technologies.

Download the full catalog to view available training carts, standalone robots, add-ons, simulation software, eLearning resources, and more.

- Hands-on robotic carts, including fenceless, enclosed, and tabletop options

- Curriculum-aligned solutions with industry credentials via NOCTI

- CNC Simulators and ROBODRILL training equipment

- Add-ons like iRVision, project kits, and collaborative EOAT

- Detailed training path and instructor certification info

Why FANUC CERT?

- Globally recognized robotics and CNC platforms

- Customizable to your curriculum or program goals

- Access to advanced certification pathways for both students and instructors

- Grant opportunities and institutional pricing available

Ready to implement FANUC training solutions in your program? Contact Us.

Pages

-

The purpose of the Certified Logistics Technician (CLT) program is to recognize through certification individuals who demonstrate mastery of the core competencies of material handling at the front-line (entry-level through front-line supervisor) through successful completion of the certification assessments.

-

Item Number:CPT / CPT+ / CPT 4.0The purpose of the Certified Production Technician (CPT) ® 4.0 certification program is to recognize through certification, individuals who demonstrate mastery of the foundational, core competencies of advanced manufacturing production at the entry-level to front-line supervisor through successful completion of the certification assessments.

-

Item Number:CT-SCAMSSC’s Certified Technician in Supply Chain Automation (CT-SCA) logistics certification enables both students and incumbent workers to gain the skills needed to meet the definition of a supply chain automation technician established by the National Science Foundation-funded National Center for Supply Chain Automation: a technician who installs, operates, supports, upgrades or maintains the automated material handling equipment and systems which support the supply chain.

-

Item Number:223-000DAC Worldwide’s Chain Drive Training System (223-000) is a heavy-duty learning aide that allows for in-depth training in industrial chain drives, heavy/silent chains, and sprocket set usage.

-

Item Number:223-PACDAC Worldwide’s Chain Drive Training System Plus (223-PAC) is a heavy-duty learning aide that allows for in-depth training in industrial chain drives, heavy/silent chains, and sprocket set usage.

-

Item Number:838-PACDAC Worldwide’s Chain Sample Board (838-PAC) is an introductory hands-on teaching aid, designed to supplement courses in chain selection and maintenance. It includes samples of eight (8) industrial-quality chains for users to learn to identify.

-

Hard Hat VR's Chemical Spill Cleanup simulation is ideal for future employees or supervisors who will work in or visit warehouses or factories. The primary goal of this course is to teach individuals safe work procedures for chemical spill cleanup.

-

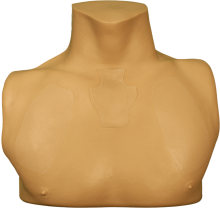

Item Number:TFX-T-CT-1The TacMed Simulation Chest Trainer is a ruggedized partial upper torso medical simulator that helps trainees during the crawl phase of training to treat patients requiring needle decompression and intraosseous (I/O) infusion. Students learn to locate realistic anatomic landmarks to execute critical patient treatment without relying on marked indicators. The unit functions as a stand-alone skills station with multiple training sites that allow for multiple uses with cost-effective replacement components.

-

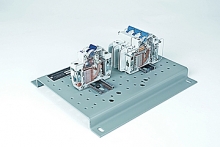

Item Number:273-906DAC Worldwide’s Circuit Breaker Cutaway Set (273-906) is a detailed, sectioned, professionally-crafted set of two circuit breaker cutaways that unveils the internal construction and operating mechanism of commonly-encountered single-pole and three-pole circuit breakers found within industrial and commercial electrical systems for circuit protection.

-

Item Number:TFX-CRL-1Experience unparalleled realism with TacMed Solutions' Clinical Response Lower (CRL) trauma trainer. This high-fidelity, remote-controlled simulator provides authentic simulations for hemostatic wound training, tourniquet application, and more. Perfect for POI, Secondary Care, and Prolonged Field Care training.