Fanuc Robotics Cert Program featured in 2015 Robozone for the STEM program at Centerline High School.

"A program enabling high school students to earn college credit by learning manufacturing skills from area employers has been expanded into Sussex County.

"A program enabling high school students to earn college credit by learning manufacturing skills from area employers has been expanded into Sussex County.

The initiative is part of Pathways to Prosperity, a partnership to prepare students with skills to work in fields such as computer science, culinary arts and hospitality management, manufacturing, biomedical science and engineering.

Under the Sussex County expansion, 20 students from Woodbridge and Seaford high schools will participate in the program's manufacturing tract.

Proven Track Record for Over 125 Years

Lincoln Electric is the world leader in the design, development and manufacture of arc welding products, robotic arc welding systems, plasma and oxyfuel cutting equipment and has a leading global position in the brazing and soldering alloys market. Headquartered in Cleveland, Ohio, Lincoln has 47 manufacturing locations, including operations and joint ventures in 19 countries and a worldwide network of distributors and sales offices covering more than 160 countries. For more information about Lincoln Electric and its products and services, visit the Company's website at www.lincolnelectric.com.

In addition to being the industry standard for welding equipment and supplies, Lincoln Electric also develops and supplies Welding Training Simulators and supplies. Tech-Labs is proud to represent Lincoln’s line of educational Welding Simulators and is your Authorized Educational Reseller.

Download Training Catalog (pdf)

Lincoln Electric is your one-stop, your one partner, — your single education resource.

We offer a full range of training solutions for educators -- teaching aids and curriculum, equipment, and consumables for every process, welding training systems, personal protection gear and tools, fume extraction, and more. Browse products organized into Levels to help you determine which training tools are right for your program.

Welding Training Systems • Robotics & Advanced Welding • Welding & Cutting Equipment • Welding & Cutting Curriculum ... and more!

Teach future skilled workers the art and craft of welding with premium welding training products including virtual trainers, weld booths, and educational packages. Instructors can engage students in production welding applications, welding techniques, robotic programming, and provide resources to advance their welding program.

Tech-Labs is proud to offer Lincoln Electric's line of virtual and automated welding training systems to educational institutions in Texas, Oklahoma. The virtual and automated training systems help welding, robotic, and manufacturing technology instructors and students develop the skills necessary to prepare for a career in the skilled trades or advanced manufacturing environment.

The rapid-fire technology developments are also widening the skills gap. Basic mechanical know-how is no longer enough; new materials, assembly processes and electronic controls make repair work more challenging. As a result, training has become more demanding, even as schools face tighter budgets and shorter classroom hours.

http://www.nytimes.com/2012/05/20/automobiles/virtual-reality-goes-to-sc...

Space Technology

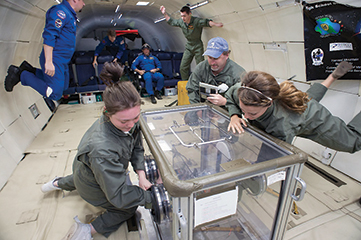

“Our kids can put on their resume that they designed and built an experiment that flew on the International Space Station.” - Matthew Brown, engineering teacher, Lakewood High School and Warren Technical School

A Colorado teacher has figured out how to use 3D printing to take his students to outer space. Matthew Brown teaches engineering and design, sustainability, renewable energy and construction at Lakewood High School and Warren Technical School, both in the Jefferson County, Colorado, school district. When Brown received a new equipment budget a few years ago, he took the opportunity to add a next-level teaching aide to his classrooms.

He researched available 3D printers with his main criterion being the ability to build parts that are strong and durable enough that they can be assembled, machined, finished, handled, tested and used in real-world applications. Brown decided that FDM technology best met his requirements so he purchased a Dimension BST 1200es 3D Printer and later added a Dimension SST 1200es 3D Printer.”

“The 3D printers have helped recruit new students,” Brown said. “When we have an open house I set one up in the hall and kids flock to it.” Brown adds that the school’s program has doubled in size since acquiring its first 3D printer: “My students learn more from their classes because they are able to touch, feel, test and use their projects as opposed to just viewing them on the computer screen. As a result, we retain more students as they move from introductory to advanced classes.””

Brown’s students are gaining hands-on experience by working on design projects with local businesses. For example, a group of students helped a local company design video game consoles for cruise ships and built the prototypes with a Dimension 3D Printer.”

Brown’s students are gaining hands-on experience by working on design projects with local businesses. For example, a group of students helped a local company design video game consoles for cruise ships and built the prototypes with a Dimension 3D Printer.”

Out-of-this-World Experiment

Jefferson County students have also used the 3D printers to collaborate with a more well-known partner. In 2013, the National Aeronautics and Space Administration (NASA) invited Brown and his students to participate in its High School Students United with NASA to Create Hardware (HUNCH) program. Through the program, NASA partners with schools to help students develop and test NASA-aimed items such as hardware and soft goods. For their project, the Jefferson County students wanted to successfully grow plants in order to provide a possible fresh food source for astronauts and evaluate potential psychological benefits.”

Plants are difficult to grow in space because the lack of gravity makes water act very differently than it does on earth. Water floats in bubbles and sticks to plants, preventing water from dripping off, causing the plants to either drown or rot. The students designed a plant chamber, called the Hydrofuge, in which the plant is suspended. The chamber is then flooded with nutrient solution. After the roots soak for several seconds, the chamber is drained and a centrifuge spins the plant to simulate gravity, drawing water off the roots. Surface tension holds the water to the sides of the chamber in a zero gravity environment. The specific angle formed by the sides and bottom of the chamber draws water along the sides to the bottom of the chamber by capillary action where it can be pumped. This process repeats several times each day to provide nutrients to the plant.”

Plants are difficult to grow in space because the lack of gravity makes water act very differently than it does on earth. Water floats in bubbles and sticks to plants, preventing water from dripping off, causing the plants to either drown or rot. The students designed a plant chamber, called the Hydrofuge, in which the plant is suspended. The chamber is then flooded with nutrient solution. After the roots soak for several seconds, the chamber is drained and a centrifuge spins the plant to simulate gravity, drawing water off the roots. Surface tension holds the water to the sides of the chamber in a zero gravity environment. The specific angle formed by the sides and bottom of the chamber draws water along the sides to the bottom of the chamber by capillary action where it can be pumped. This process repeats several times each day to provide nutrients to the plant.”

3D printing played an instrumental role in this experiment. “The 3D printer made it possible for us to go through the complete engineering process,” said Trevor Lucero, a senior at Lakewood High School. The students performed engineering calculations, developed the concept design and printed the two primary system parts – the centrifuge container which includes the root chamber and the water chamber – on a Dimension 3D Printer in ABSplus™ thermoplastic. The two parts were sealed with silicone caulk and bolted together. The students evaluated the prototype, made changes to the design, then printed new prototypes overnight and performed functional testing.”

3D printing played an instrumental role in this experiment. “The 3D printer made it possible for us to go through the complete engineering process,” said Trevor Lucero, a senior at Lakewood High School. The students performed engineering calculations, developed the concept design and printed the two primary system parts – the centrifuge container which includes the root chamber and the water chamber – on a Dimension 3D Printer in ABSplus™ thermoplastic. The two parts were sealed with silicone caulk and bolted together. The students evaluated the prototype, made changes to the design, then printed new prototypes overnight and performed functional testing.”

Zero-Gravity Testing

When they had a design that seemed to work on earth, they tested it in zero gravity at Johnson Space Center in Houston. There were several things that became evident during testing, including which materials worked best as a grow medium for the plants in a microgravity environment and how to use a centrifuge to remove water from the roots. To simplify the design, they moved from an aeroponic nutrient delivery system to a flood and drain system. The size of the first design also had to be reduced by almost 75% for the final design. After five zero-gravity flights, the students’ design appears to work perfectly in a weightless environment. It launched in SpaceX CRS-6, a cargo resupply mission to the ISS, on April 14, 2015. There are now tests being conducted on an aquaponics system to provide nutrients to the plants and provide a new source of protein to Astronauts.”

“Our 3D printers have proven to be well worth the investment. Just think, our kids can put on their resume that they designed and built an experiment that flew on the International Space Station.”

Instructors and distributors discuss the advantages of a REALWELD® Trainer for weld training environments at every level – it’s like having a personal trainer in every booth.

Headquartered in the heart of Madison, Wisconsin, Madison Area Technical College is one of the largest of 16 schools in the Wisconsin Technical College System. It serves some 40,000 people and 12 counties in south-central Wisconsin.

Madison College was recently named a partner in providing mobile technical training opportunities to restore the economic health of the region. Through a grant from the Economic Development Administration (EDA), Madison College purchased FANUC Robotics' Certified Education Robot Training Carts, or CERT Carts, in order to train students in Advanced Automated Manufacturing.

EQUIPPING STUDENTS WITH DESIGN ENGINEERING TOOLS TO BE COMPETITIVE

Dimension 3D Printers help teach design concepts in: Architecture, Industrial Design, Medical Design, Sculpting, Mechanical Engineering, 3D Animation, Cartography, Visual Arts, Graphic Design, & Science / Math.

Dimension 3D Printers provide an affordable, easy to use, easy to maintain, one-step process for students and instructors to explore concepts in durable ABS plastic. It’s as simple to use as printing a file.

Dimension 3D Printers are helping high schools, technical colleges and universities extend their science, CAD and machine tool curriculums by enabling students to build functional 3D models and see their ideas first-hand.

Innovative designers, engineers, architects and manufacturers consider prototyping a critical step of the design process. As the use of CAD and 3D printing increases throught the design process, understanding this technology is critical for design students. With a Dimension 3D Printer, students and educators can now easily bring design ideas to life in ABS plastic - right from a CAD file.

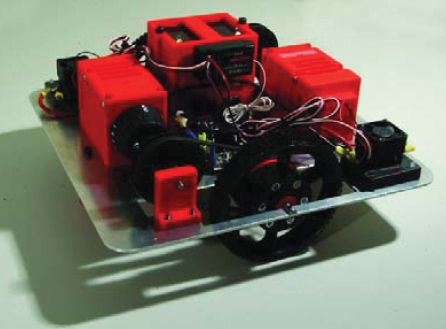

Innovation fueled by fun – that’s what students can look forward to when they sign up for the Robotics Challenge, the Engineering Club or enroll in one of Bruce Mazer’s Computer Engineering courses at Bishop Reding Secondary School in Milton, Ontario.

Bishop Reding offers four Computer Engineering courses starting in grade 9 and extending to grade 12 as well as a summer engineering camp for grade 7 and 8 students. The course of study is essentially a pre-mechatronics program and is designed to teach students how to create useful, intelligent products by employing skills and concepts from across the engineering spectrum including mechanical, electrical, design and computer engineering.

“The Computer Engineering courses demand that students take a look at a variety of systems and components that allow new products and devices to work properly,” said Mazer. “This can include programming software, mechanical design, ergonomics, etc. – all the things that might go into designing a cell phone, for instance.”

Successfully working through the design of a new product frequently requires that the students manufacture custom parts and components. This stage of the process proved difficult for students and teachers prior to purchasing the Dimension 3D printer.

“We worked in the manufacturing and construction labs to fabricate parts from metal and wood, but more often than not, these parts did not meet the required design specification” said Mazer. “When our school board technology consultant, Robert DeRubeis, saw a Dimension 3D printer in action at the ITEA and OCTE conferences, he knew it was just what was needed to enhance the ‘fabrication’ portion of our program.” With the support of Rick MacDonald, Superintendent of Curriculum Services, the board purchased two Dimension 3D Printers.

Pages

-

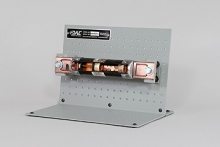

Item Number:273-960DAC Worldwide’s Dual Element, Time-Delay Fuse Cutaway (273-960) is a detailed and professionally-crafted electrical fuse cutaway that depicts a common dual-element, time-delay industrial fuse.

-

Quickly and seamlessly switch between our end or arm tooling solutions for collaborative robots to maximize the utilization of your robots with the Dual Quick Changer.

-

Revolutionize operator safety training: introducing real-world challenges with dynamic fault injection.

-

Item Number:EEA/1000 (Manual) and EEA/2000 (Computerized)Explore Pignat’s EEA/1000 and EEA/2000 ebulliometers for studying binary mixtures, boiling point determination, and liquid-vapor equilibrium under atmospheric and vacuum conditions. Ideal for chemical engineering education and lab research.

-

The EDU MiNi MiLL is a compact CNC milling machine designed for educational environments, providing students with hands-on training in modern machining. Ideal for technical training programs and research projects.

-

Discover the EDU RoboMill from Levil Technology—an all-in-one CNC and robotics training system featuring FANUC CNC control and robot integration. Ideal for Industry 4.0 education and workforce development.

-

Item Number:EDU-MiLLThe EDUMiLL is a revolutionary system that incorporates technologies from the additive and subtractive manufacturing fields to open the door to a new realm of possibilities and further innovation by making it affordable to include a 3D printer and a robust CNC mill in one package.

-

Item Number:85-MT5Amatrol’s Electric Motor Control Learning System (85-MT5) covers electric relay control of AC electric motors found in industrial, commercial, and residential applications. Learners study industry-relevant skills including how to operate, install, design, and troubleshoot AC electric motor control circuits for various applications.

-

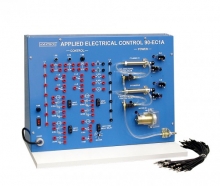

Item Number:90-EC1AThe Applied Electrical Control Learning System (90-EC1-A) teaches learners how to interpret, design, and operate relay control circuits using ladder diagrams. Electrical control is vital in the operation of electric and fluid power actuators and also forms the fundamental building block of automation systems like programmable logic controllers (PLCs), which are programmed using the electrical control schematic method, the ladder diagram.

-

Item Number:ERSThere are eight "Simulation Modules" of increasing difficulty, starting with Controls Familiarization. The final modules combine elements of dipper fill at the rock face, and cab-side or blind-side truck loading. A simulated Mining Truck is built right in, to help teach truck spotting interaction. Key "Performance Indicators" measure how quickly and how carefully the simulated work is performed.