Date: Wednesday, September 24 to Friday, September 26, 2025

Date: Wednesday, October 15 to Thursday, October 16, 2025

Date: Thursday, October 23, 2025

Location: Grapevine Convention Center

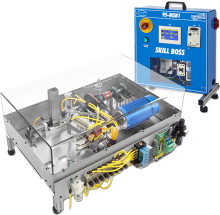

Amatrol Skill Boss Manufacturing

Amatrol’s Skill Boss Manufacturing is a portable, hands-on training and assessment system designed to meet the rigorous standards of the Manufacturing Skill Standards Council (MSSC). Built for the Certified Production Technician (CPT+) program, this system evaluates over 60 essential skills across safety, quality practices, production processes, and maintenance awareness.

The Skill Boss system replicates real-world manufacturing tasks, including assembly, machine operation, and troubleshooting. Learners gain practical experience with components such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), electro-pneumatic systems, sensors, mechanical drives, and robotic pick-and-place systems. By completing CPT+, individuals prove both their technical knowledge and applied competency, making them job-ready for advanced manufacturing careers.

- Assess and train in Safety, Quality, Production, and Maintenance

- Hands-on demonstrations in electrical, fluid power, mechanical, and electronic systems

- Supports MSSC’s Certified Production Technician Plus (CPT+) certification

- Portable design for classrooms, training centers, and workforce development programs

With its real-world finishing and sorting process, Skill Boss Manufacturing automatically feeds, sorts, and polishes parts, while learners control and monitor operations. The system’s design provides educators and employers with a reliable way to both develop and validate critical advanced manufacturing skills.

Levil Technology EDU-RoboMill: CNC Precision Meets FANUC Robotics

The EDU-RoboMill brings together the world of CNC machining and FANUC robotics in a single, compact solution designed for both education and industrial applications. Built with precision and durability in mind, the RoboMill allows students to practice robot programming, CNC fundamentals, and integrated automation—all in a footprint that fits through a standard 35″ doorway. Its combination of industrial-grade controls and accessible design makes it the perfect choice for classrooms, labs, and training centers preparing the next generation of advanced manufacturing professionals.

- Robot G-code Control: FANUC CNC issues coordinated X/Y/Z moves to the robot, enabling true CNC-style motion paths.

- Compact & Classroom-Ready: Fits standard doorways and runs on single-phase power for easy integration into labs.

- High Precision: Achieves repeatability down to ~0.0012 in (0.03 mm).

- Spindle Options: Configurable spindles with automatic tool changer (ATC), high-speed air-cooled motors, and rigid tapping capability.

- Industrial Flexibility: Train in robotics, CNC machining, and real-world automation tasks on one versatile platform.

Technical Highlights

- Precision & Feeds: ~0.0012 in (0.03 mm) precision; 79 ipm rapid feed; 59 ipm cutting feed.

- Power: 220 VAC, single-phase, 15 A (step-up/down transformer available for 110 VAC).

- Drive System: In-line direct drive with linear guideways and ball screws for smooth motion.

- Spindle Speeds: Options up to 30,000 rpm depending on configuration.

- Dimensions: 83.6″ W x 74.7″ H x 32.9″ D; fits through 35″ doorway.

FANUC Robot Compatibility

- LR-Mate 200iD/4S

- LR-Mate 200iD

- LR-Mate 200iD/7L

- LR-Mate 200iSD/14L

- LR-10iA/10

Other FANUC robots may be used; larger models may affect doorway clearance and table dimensions.

Gateway Technical College (GTC) is helping shape the workforce of tomorrow with its Smart Factory lab located at the SC Johnson Integrated Manufacturing and Engineering Technology (iMET) Center in Sturtevant, Wisconsin. As the first publicly funded technical college in the United States, GTC continues to lead by preparing students with the skills needed for Industry 4.0.

This advanced lab simulates a real-world production line where students gain hands-on experience in “lights out” manufacturing, automation, and data analytics. Learners work with programmable logic controllers (PLCs), human-machine interfaces (HMIs), industrial controllers, and smart sensors to understand how modern factories operate. By integrating connectivity and data analysis, the lab demonstrates how to unlock siloed information and apply it to real-world decision-making.

One of the lab’s most exciting features is its development of a digital twin—a virtual replica of the physical environment that collects and processes real-time data from robotics, machinery, and sensors. This allows students to explore artificial intelligence, advanced automation, and smart technologies that are rapidly transforming the manufacturing industry. By engaging with this innovative environment, students are better prepared to become the highly skilled employees industry partners need today and in the future.

Industrial Absorption Principles for Education & Research

Teaching Industrial Absorption Through Real Experiments

Absorption is a critical separation process in chemical engineering, widely applied in industries such as environmental engineering, pharmaceuticals, and petrochemicals. Pignat’s absorption training systems provide hands-on learning by simulating real-world gas–liquid interactions, enabling students to explore both the theory and practice of mass transfer operations.

These systems are designed for flexibility and precision, helping learners understand core concepts such as absorption efficiency, column design, and operating parameters. Whether used in an undergraduate classroom or an advanced research lab, Pignat’s absorption units bridge the gap between academic knowledge and industrial practice.

Key Learning Outcomes

- Understand the fundamentals of gas–liquid absorption processes

- Explore packed and tray column designs

- Measure and analyze absorption efficiency under varied conditions

- Apply theoretical principles to real-world separation challenges

Solid–Fluid Adsorption Principles for Engineering Labs

Hands-On Solid–Fluid Interaction Experiments

Adsorption plays a vital role in chemical engineering and industrial applications, from gas purification and pollution control to water treatment and chemical recovery. Pignat’s adsorption training units enable students to study surface phenomena, adsorption isotherms, and regeneration techniques.

These versatile systems demonstrate the behavior of gases and liquids when interacting with solid surfaces, offering real-world insight into adsorption processes that industries rely on daily.

Key Learning Outcomes

- Understand adsorption isotherms and kinetics

- Examine breakthrough curves and column design

- Study regeneration and reuse of adsorbents

- Apply adsorption theory to environmental and industrial challenges

Crystallization Principles for Future Engineers

Explore the Science of Crystallization with Pignat

Crystallization is a widely used process in chemical, pharmaceutical, and food industries for product purification and separation. Pignat’s crystallization units provide a hands-on approach to studying solubility, cooling rates, and crystal formation.

Students gain real-world understanding of crystal nucleation and growth, learning how operational conditions affect product quality and purity.

Key Learning Outcomes

- Examine solubility and saturation principles

- Study the impact of cooling and evaporation on crystallization

- Analyze crystal growth and size distribution

- Apply solid–liquid separation concepts to industrial processes

Train Students in Industrial-Scale Distillation Concepts

From Classroom to Industry: Distillation Education

Distillation is one of the most common and important separation methods in the chemical process industry. Pignat’s distillation training systems bring industrial operations into the classroom, teaching fractional distillation, column efficiency, and reflux control.

These systems allow students to analyze mixtures, understand boiling point differences, and optimize process conditions—all while reinforcing real-world chemical engineering skills.

Key Learning Outcomes

- Perform simple and fractional distillation experiments

- Examine column efficiency and operating parameters

- Understand reflux and product purity control

- Apply separation principles to multi-component systems

Pages

-

Item Number:T7082Amatrol’s Air Conditioning/Heat Pump Operations Learning System (T7082) features industry-standard heating and cooling components that form a working heat pump trainer, ac trainer and refrigeration system.

-

Item Number:T7082AAmatrol’s Air Conditioning / Heat Pump Troubleshooting Trainer (T7082A) teaches valuable HVAC troubleshooting skills on a hands-on learning system that performs heat pump, air conditioning and refrigeration operation.

-

Amatrol’s FaultPro computer-based fault insertion software is the industry’s only electronic troubleshooting training system. FaultPro allows instructors to instantly set and tailor faults to test a student’s weaknesses and turn them into strengths.

-

Item Number:95-MSB1Amatrol's Skill Boss Manufacturing is a hands-on training and assessment tool for CPT+ certification that meets MSSC standards easily integrates into manufacturing programs.

-

Item Number:87-TMSTrain future technicians with Amatrol’s Tabletop Smart Factory and Cobot-Integrated Mechatronics systems—hands-on, compact training with real industrial components, Rockwell Automation integration, and FANUC CRX collaborative robotics.

-

Each Advanced Manufacturing topic incorporates the skill development needed for modern industry. From operation to complex troubleshooting, Amatrol’s learning systems deliver job-ready skills.

-

Item Number:T7045Amatrol’s Basic Refrigeration training system (T7045) offers hands-on learning of a working refrigeration system in a compact tabletop unit.

-

Item Number:T7200Amatrol’s Combined Refrigeration Installation Learning System (T7200), an ideal training tool for HVAC/R technicians, offers a comprehensive hands-on workstation and interactive multimedia curriculum to teach installing electrical and mechanical refrigeration/air conditioning components in residential or light commercial applications.

-

Item Number:T7083Amatrol's Environmental Applications Learning System (T7083), an expansion for the Air Conditioning / Heat Pump Operations Learning System (T7082) or the Troubleshooting Learning System (T7082A), is a model of a house complete with insulation, siding, shingles, and a window.

-

Item Number:CRX 5iA | CRX-10iA | CRX-10iA/L | CRX 20iA/L | CRX 25iAExperience the all-new CRX Series, FANUC's latest collaborative robot designed to make installation and programming your cobots easier than ever before.