Hands-On Skills with Parallel and Series Pumps

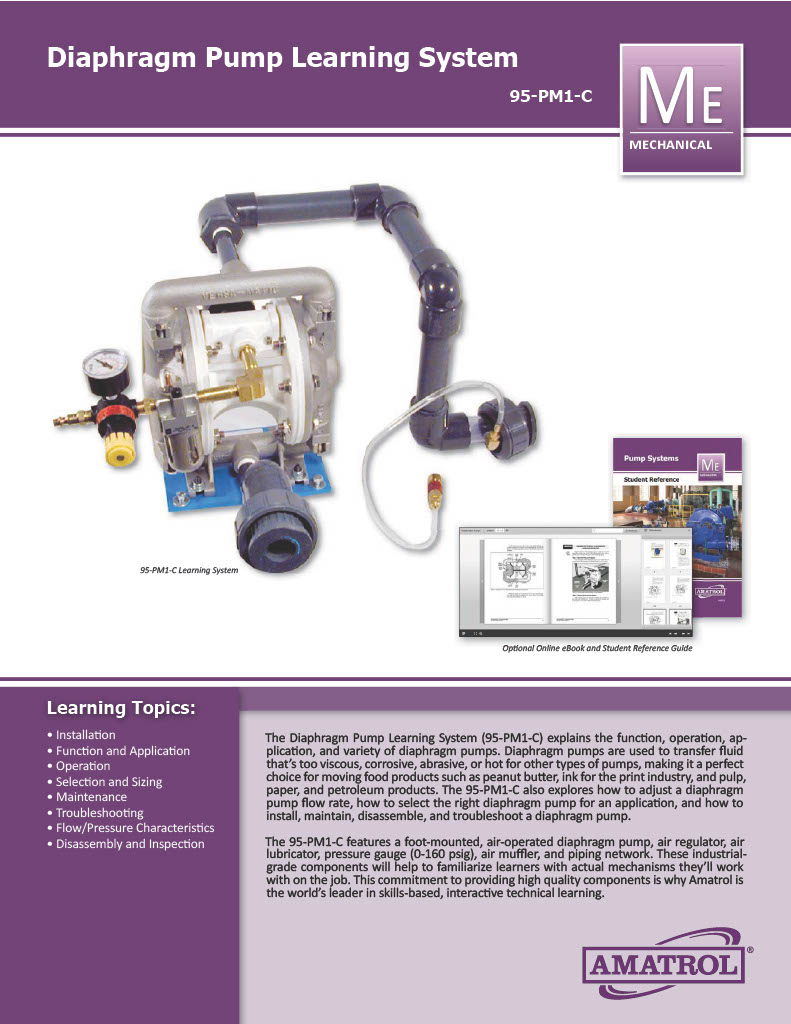

The Diaphragm Pump Learning System (95-PM1-C) explains the function, operation, application, and variety of diaphragm pumps. Diaphragm pumps are used to transfer fluid that’s too viscous, corrosive, abrasive, or hot for other types of industrial pumps, making it a perfect choice for moving food products such as peanut butter, ink for the print industry, and pulp, paper, and petroleum products. The diaphragm pump training system explores how to adjust a diaphragm pump flow rate, how to select the right diaphragm pump for an application. It also covers pump installation, pump maintenance, disassembly, and pump troubleshooting.

Pump Maintenance & Troubleshooting Skills

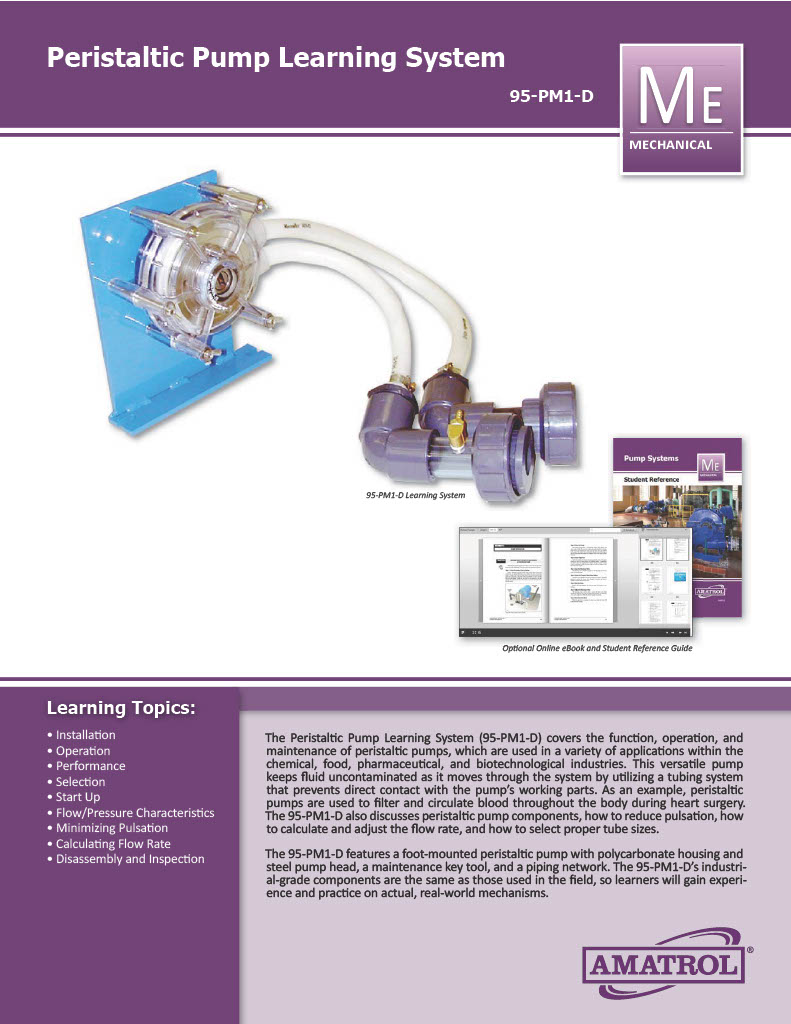

The Peristaltic Pump Learning System (95-PM1-D) covers the function, operation, and maintenance of peristaltic pumps, which are used in a variety of applications within the chemical, food, pharmaceutical, and biotechnological industries. This versatile pump keeps fluid uncontaminated as it moves through the system by utilizing a tubing system that prevents direct contact with the pump’s working parts. As an example, peristaltic pumps are used to filter and circulate blood throughout the body during heart surgery. This industrial pump training system also discusses peristaltic pump components, how to reduce pulsation, how to calculate and adjust the flow rate, and how to select proper tube sizes.

Pump Maintenance and Troubleshooting

The Piston Pump Learning System (95-PM1-E) provides learners with an in-depth overview of the piston pump, which has been in use longer than any other type of pump. The piston pump produces high pressure fluid flow of water, soaps and detergents in various applications within the aerospace, marine, agriculture, and auto industries. Within the world-class curriculum, learners will study piston pump set-up, operation, flow/pressure characteristics, maintenance, and troubleshooting for this highly efficient pump. Learners will also study how to connect the pump to a motor, how to adjust the flow rate, and how to calculate theoretical and actual flow rates.

Industrial Pump Maintenance and Troubleshooting

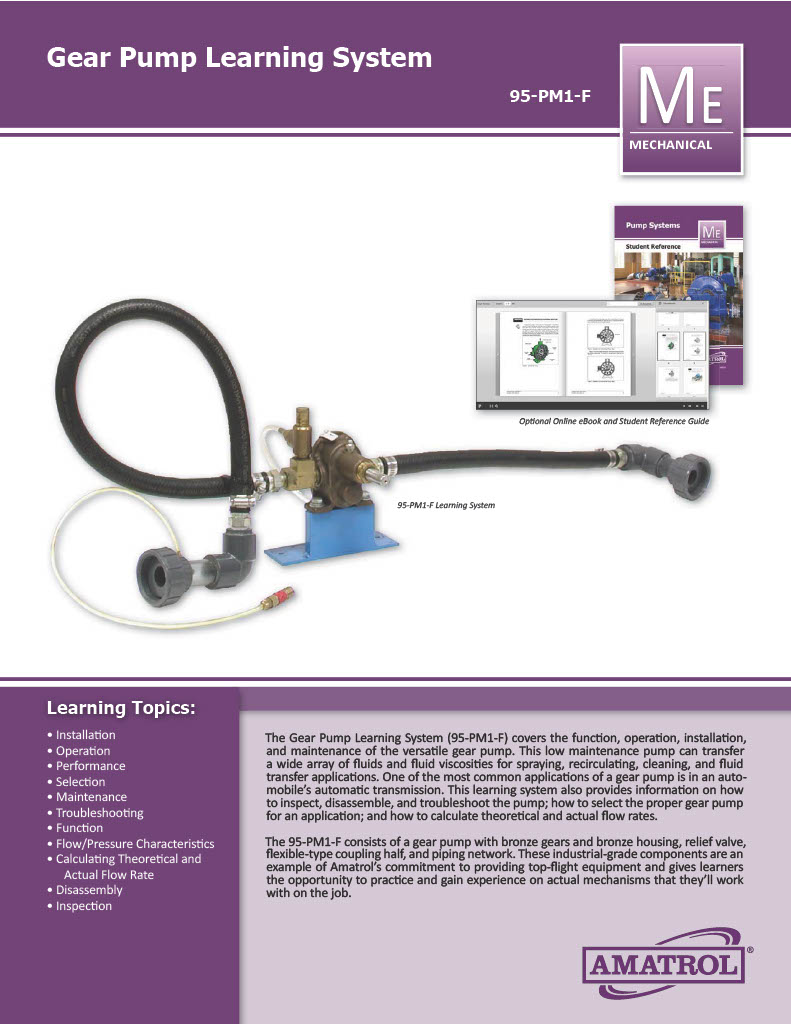

The Gear Pump Learning System (95-PM1-F) covers the function, operation, installation, and maintenance of the versatile gear pump. This low maintenance pump can transfer a wide array of fluids and fluid viscosities for spraying, recirculating, cleaning, and fluid transfer applications. One of the most common applications of a gear pump is in an automobile’s automatic transmission. This industrial pumps training system also provides information on pump inspection, pump disassembly, pump maintenance, and pump troubleshooting, as well as how to select the proper gear pump for an application and how to calculate theoretical and actual flow rates.

Pump Maintenance & Troubleshooting Skills

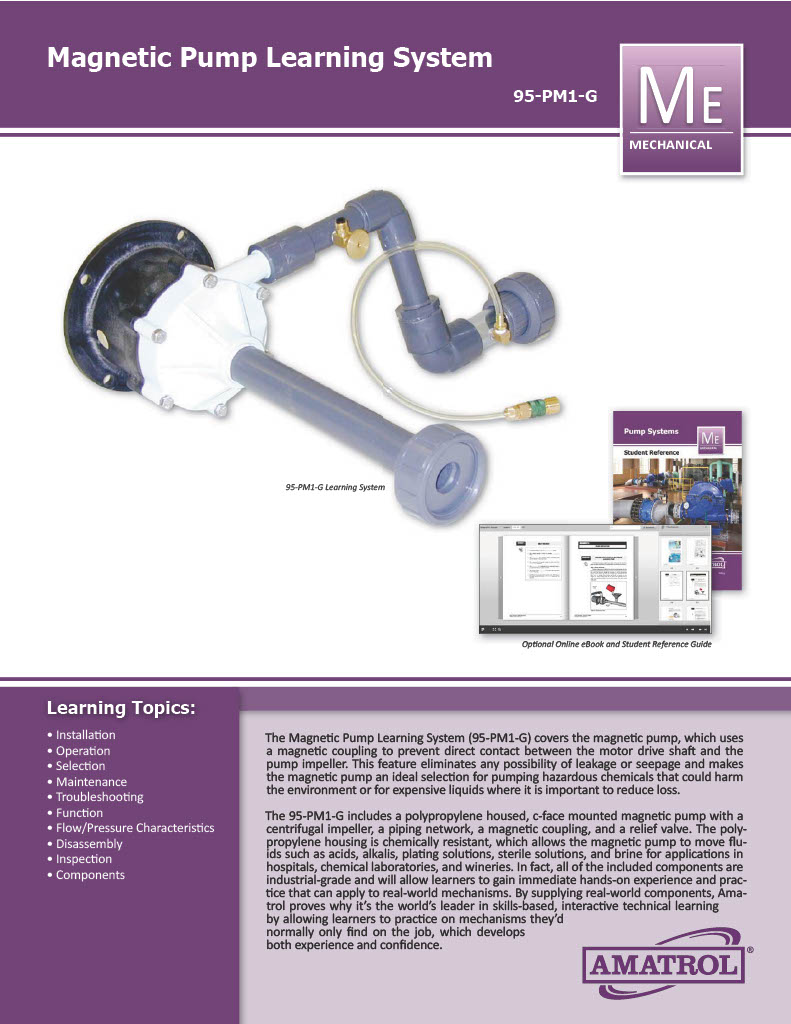

The Magnetic Pump Learning System (95-PM1-G) covers the magnetic pump, which uses a magnetic coupling to prevent direct contact between the motor drive shaft and the pump impeller. This feature eliminates any possibility of leakage or seepage and makes the magnetic pump an ideal selection for pumping hazardous chemicals that could harm the environment or for expensive liquids where it is important to reduce loss. This industrial pumps training system explains the function, operation, installation, disassembly, inspection, and maintenance of a magnetic pump.

Additional topics include: how to properly align the magnetic coupling; how to troubleshoot problems; how to select the correct magnetic pump for an application; how to determine a pump’s flow/pressure characteristics; and how each component of the pump factors into the overall operation.

Pump Maintenance Skills

The Centrifugal Pump with Stuffing Box Learning System (95-PM1H) covers a pump design that, in spite of the modern mechanical seal, remains widely used in industry due to its cost-effectiveness and ability to avoid catastrophic failure. This feature makes it an ideal design for fire departments in fire pump applications. This industrial pumps training system explains the installation, function, and maintenance of a centrifugal pump with a stuffing box.

Additional topics include: how to troubleshoot this pump design; what the flow/pressure characteristics of a centrifugal pump are; and how to startup and operate a centrifugal pump with a stuffing box.

The model 950-PM1 Centrifugal Pumps Training System teaches skills related to centrifugal pumps training, which are used in almost every industry to transfer non-hydraulic fluids of various types from one place to another. Students learn a comprehensive set of industry-relevant skills including how to operate, install, maintain, troubleshoot, analyze performance, and select centrifugal pumps as well as system design.

The model 950-PM1 includes a centrifugal pump, mobile test workstation, student learning materials for both theory and lab, and teacher’s guide. This centrifugal pumps operation and maintenance training system uses industrial quality components such as a cast iron centrifugal pump to help students become better prepared for what they will encounter on the job.

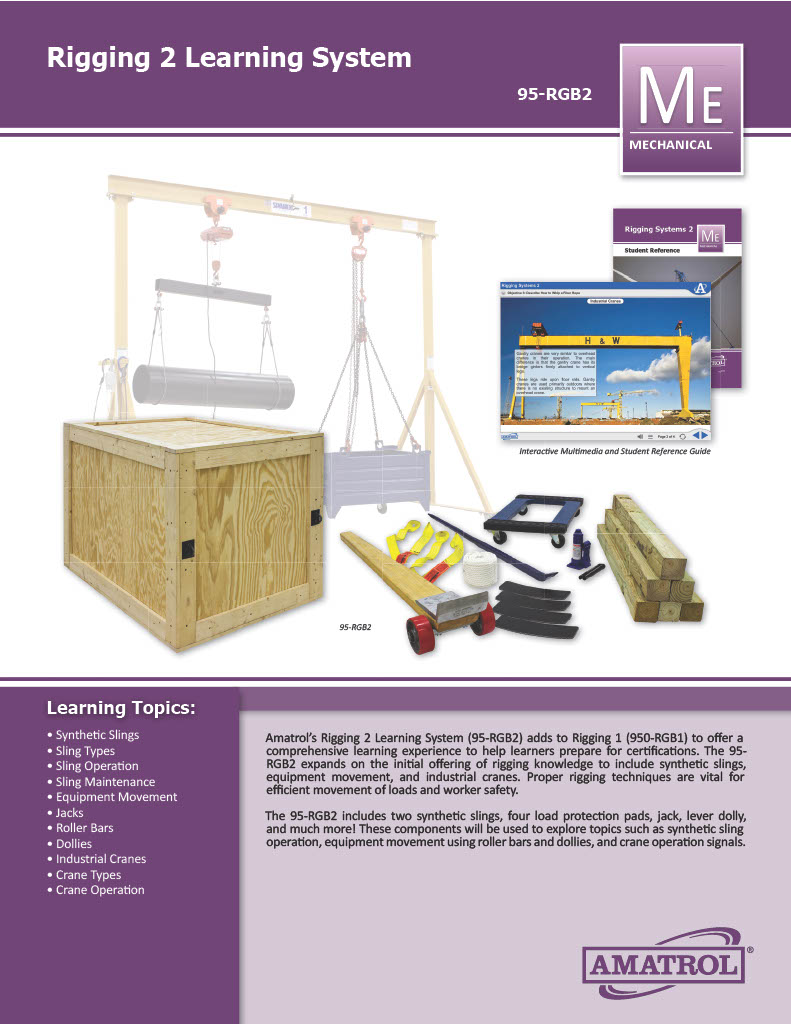

Amatrol’s Rigging 2 Learning System (95-RGB2) adds to the first Rigging training system (950-RGB1) to offer a comprehensive learning experience, to teach rigging safety training and industrial crane operation skills, and to help learners prepare for certifications. This hands-on Rigging training system expands on the initial offering of rigging knowledge to include synthetic slings, equipment movement, and industrial cranes. Proper rigging techniques are vital for efficient movement of loads and workers safety.

This Crane Operation training course includes two synthetic slings, four load protection pads, jack, lever dolly, and much more! These components will be used to explore topics such as synthetic sling operation, equipment movement using roller bars and dollies, and crane operation signals. In addition to equipment and printed curriculum, this industrial system offers a student reference guide, instructor’s manual, installation guide, and an optional online rigging training course.

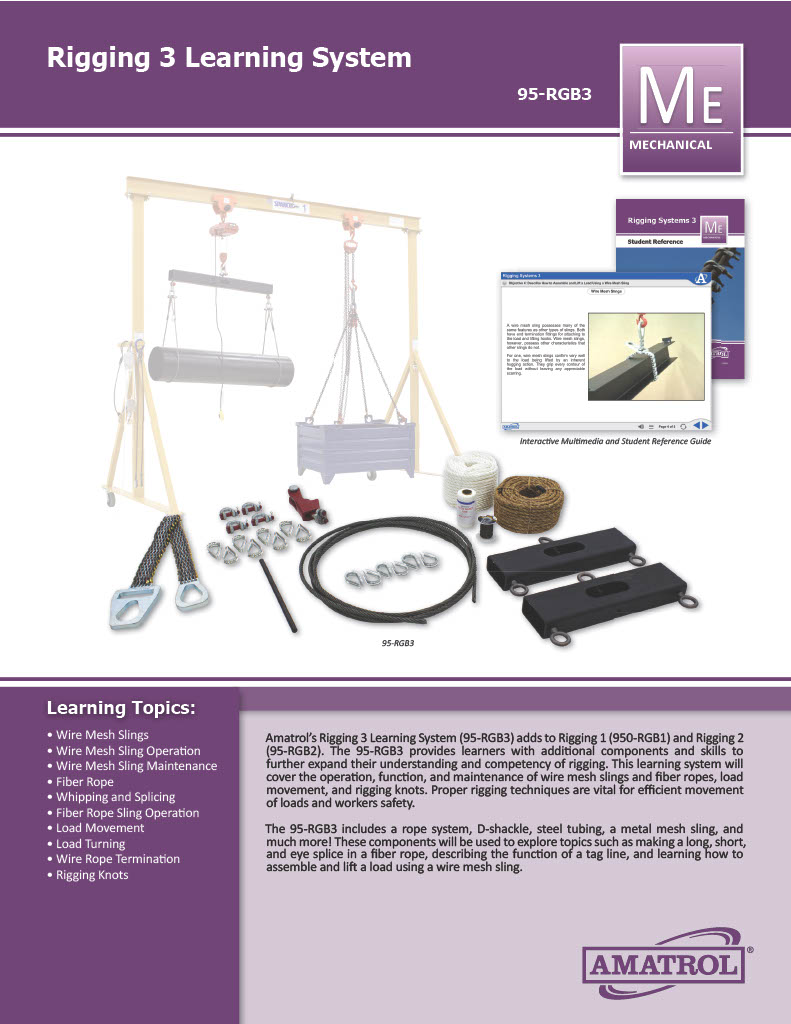

Amatrol’s Rigging 3 Learning System (95-RGB3) adds to the initial hands-on rigging training systems (950-RGB1 and 95-RGB2) by including hands-on wire mesh sling skills, rigging knots training, and rigging safety skills. This advanced rigging training system provides learners with additional components and skills to further expand their understanding and competency of rigging. Proper rigging techniques are vital for efficient movement of loads and workers safety.

This advanced rigging training system includes a rope system, D-shackle, steel tubing, a metal mesh sling, and much more! These components will be used to explore topics such as making a long, short, and eye splice in a fiber rope, describing the function of a tag line, and learning how to assemble and lift a load using a wire mesh sling. In addition to equipment and printed curriculum, this system offers a student reference guide, instructor’s manual, installation guide, and an optional online eBook.

Amatrol’s Solar Site Analysis Training System (95-SA1) teaches learners both the theoretical knowledge and hands-on skills they will need to analyze and choose suitable locations for solar arrays and components. Learners begin by studying how to conduct a preliminary site assessment, including applicable codes, jurisdictional authorities, permits, and licenses required for solar energy system installations.

Learners will also use real-world equipment, like the Solar Pathfinder sun path calculator, to perform and interpret a shading analysis in order to determine suitable locations for electrical photovoltaic and solar thermal components. The included multimedia curriculum also teaches other relevant skills, such as developing site layout drawings.

Pages

-

Item Number:850-AESAmatrol’s Solar Energy Learning System (850-AES) teaches hands-on PV installation, wiring, and troubleshooting. Prepares students for NABCEP and ETA certifications with real-world components and engaging eLearning.

-

Item Number:850-AECAmatrol’s Alternative Energy Learning System – Wind and Solar (850-AEC) covers basic alternative energy training through a combination of eLearning curriculum and hands-on experience.

-

For agriculture skills training, Amatrol offers training programs that feature a combination of learning methods to engage students' learning styles. Amatrol's training solutions include eLearning curriculum and hands-on, industrial-quality training systems for both industry and education settings.

-

Item Number:950-HTB1Amatrol’s Basic Hydraulic Troubleshooting Learning System (950-HTB1) teaches how to troubleshoot hydraulic systems and components such as hydraulic motors, directional control valves, and cylinders. The knowledge gained from the 950-HTB1’s hardware and curriculum is extremely valuable for maintenance technicians within industries like manufacturing, automotive, agriculture, construction, and many more! This learning system will also serve as a solid foundation towards attaining certifications.

-

Amatrol’s e-Learning program meets the challenge for flexible technical training by offering superb technical content depth as well as breadth, strong interactivity for skill development, and excellent assessment and student tracking through an intuitive, easy-to-use web portal. With 24 x 7 access, Amatrol’s eLearning program creates easy access to educational opportunities for technical skill development previously restricted to the classroom...

-

Amatrol's eAssessment streamlines technical skills assessment and training with assessment tests to individually determine a CTE student's skill level in specific areas to dramatically improve training effectiveness and efficiency while reducing training cost and time.

-

Online training is an essential tool in today’s workplace and educational institutions. Amatrol is increasing its already extensive online offerings with the introduction of eBooks. Amatrol’s eBooks are digital versions of its print-based LAPs (Learning Activity Packets) that allow organizations to set up courses completely online, including assessments!

-

Item Number:85-MT2E Regular / 85-MT2ESL Sheathed Banana LeadsThe Motor Troubleshooting Learning System (85-MT2E) covers the testing and troubleshooting of AC and DC motors using a multimeter and a megger meter. The skills and knowledge covered by this learning system will prove invaluable for industrial maintenance technicians or anyone working in a field that uses AC and/or DC motors.

-

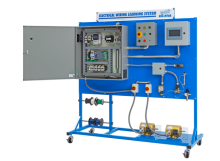

Item Number:850-MT6BAmatrol’s 850-MT6B Electrical Wiring Learning System allows students to learn electrical wiring skills hands-on.

-

Item Number:950-HM1Train students and technicians in essential hydraulic maintenance with Amatrol’s 950-HM1 Learning System. Learners will gain hands-on experience in fluid servicing, fittings, seals, tubing, hoses, and component installation using industry-standard equipment.