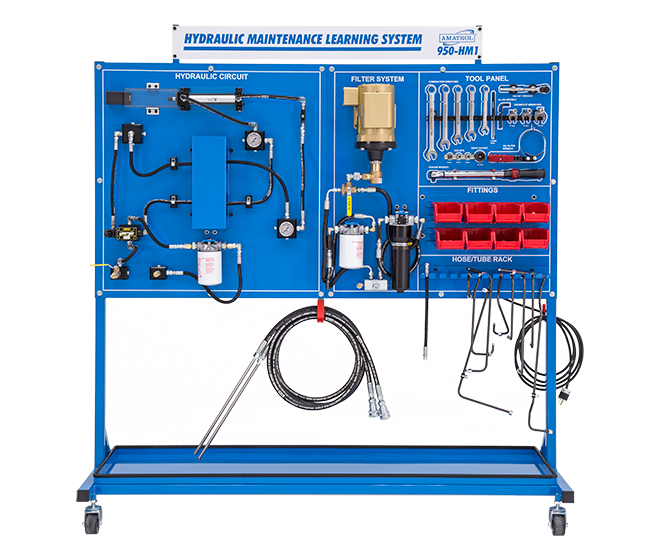

Amatrol Hydraulic Maintenance Learning System

Hydraulic systems are critical across industries such as automotive, packaging, pharmaceuticals, and food processing. Amatrol’s training system equips learners with the skills needed for real-world maintenance and installation by covering filter and fluid servicing, fittings, seals, hoses and clamping devices, tubing, and hydraulic component installation. Designed for industrial maintenance technicians, system installers, and other technical professionals, this system delivers both foundational knowledge and hands-on practice.

The system includes a mobile workstation, hose set and tubing rack, flush cart module, fittings module, component panel, and fluid servicing kit. Built with industry-standard components, it ensures learners practice on equipment identical to what they’ll encounter in the field. Training exercises build confidence and competence in key tasks, such as replacing spin-on filters and strainers, adding fluid, installing O-ring seals, bleeding hydraulic cylinders, and properly mounting and aligning components.

Hydraulic Installation and Fluid Maintenance

Amatrol’s hydraulic training system combines theory with hands-on practice to help learners build real-world skills. Students gain experience installing hydraulic tubing with thread sealant and ferrule fittings, connecting hoses with push-lock fittings, and working with both adjustable and non-adjustable STOR (Straight Thread O-Ring) fittings. The 950-HM1 also features a flush cart module, allowing learners to replace and clean hydraulic fluid as part of their training.

Hydraulic Maintenance Training Exercises

The 950-HM1 curriculum provides the essential knowledge and practice for basic hydraulic system maintenance. Learners will gain experience adding and checking hydraulic fluid, flushing systems, installing and identifying O-ring fittings, bleeding cylinders, and installing hydraulic tubing. Objectives also include understanding eight types of hydraulic fittings, three hose clamping devices, and how to replace a body-ported valve. Interactive multimedia lessons feature 3D graphics, videos, voice narration, and quizzes to enhance engagement and retention.

Flexible Learning Systems for Hydraulic Training

The 950-HM1 is part of Amatrol’s complete line of hydraulic training systems. It can be paired with its own hydraulic power unit (85-HPS) or used with the 85-HPS included in other systems. Amatrol also offers Intermediate Hydraulics (850-IH), Advanced Hydraulics (85-AH), and Electro-Hydraulics (85-EH), providing scalable training options for every level of learner.

Student Reference Guide Included

A sample Hydraulic Maintenance Student Reference Guide comes with the system for evaluation. This bound guide condenses the curriculum’s technical content into a convenient format, serving as both a classroom supplement and a valuable reference tool after training—an ideal takeaway for students.

Learning Topics

- Hydraulic Filter Maintenance

- Hydraulic Fluid Maintenance

- Adding Hydraulic Fluid

- Flushing Hydraulic Systems

- Fittings and Seals

- O-Ring Seals

- Hose and Clamping Devices

- Clamps, Brackets, and Clips

- Cylinder Bleeding

- Tubing and Component Installation

- Component Replacement

Key Features

- Teaches skills related to servicing and maintaining hydraulic systems and components

- Includes a mobile workstation, hose set and tubing rack, flush cart module, fittings module, component panel, and fluid servicing kit

- Valuable skills include: installing hydraulic tubing using thread sealant and ferrule fitting; installing hydraulic hoses with a push-lock hose fitting; and installing adjustable and non-adjustable straight thread O-ring (STOR) fittings

Product Options

- Tool Kit

- Hydraulic Power Unit (85-HPS)