Simlog’s Wheeled Material Handler Personal Simulator puts students at the controls of a modern Material Handler at work in a typical scrap metal recycling yard.

Training efficiency is delivered through a modular Instructional Design that teaches real skills for productive and safe equipment operations in the field.

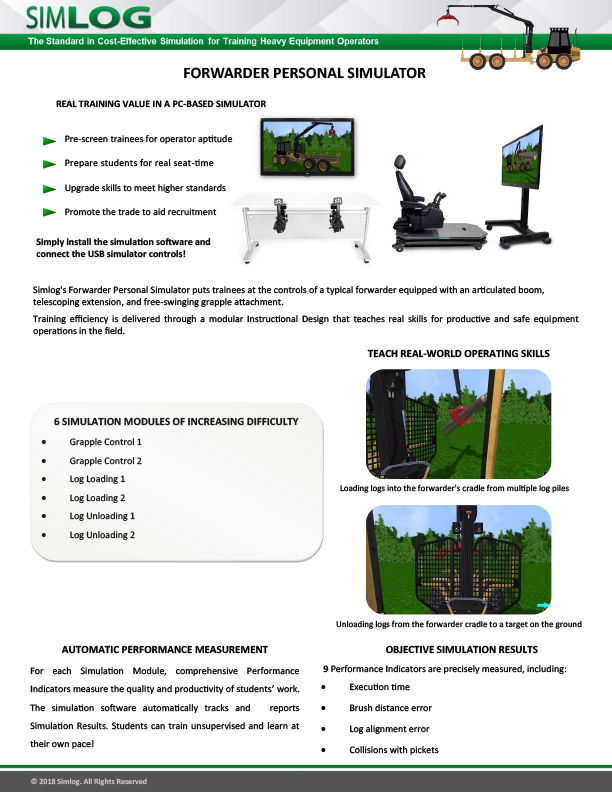

Simlog's Forwarder Personal Simulator puts trainees at the controls of a typical forwarder equipped with an articulated boom, telescoping extension, and free-swinging grapple attachment.

Training efficiency is delivered through a modular Instructional Design that teaches real skills for productive and safe equipment operations in the field.

Simlog's Harvester Personal Simulator puts students at the controls of a tracked carrier equipped with an articulated boom and free-swinging "dangle-type" harvester head.

Training efficiency is delivered through a modular Instructional Design that teaches real skills for productive and safe equipment operations in the field.

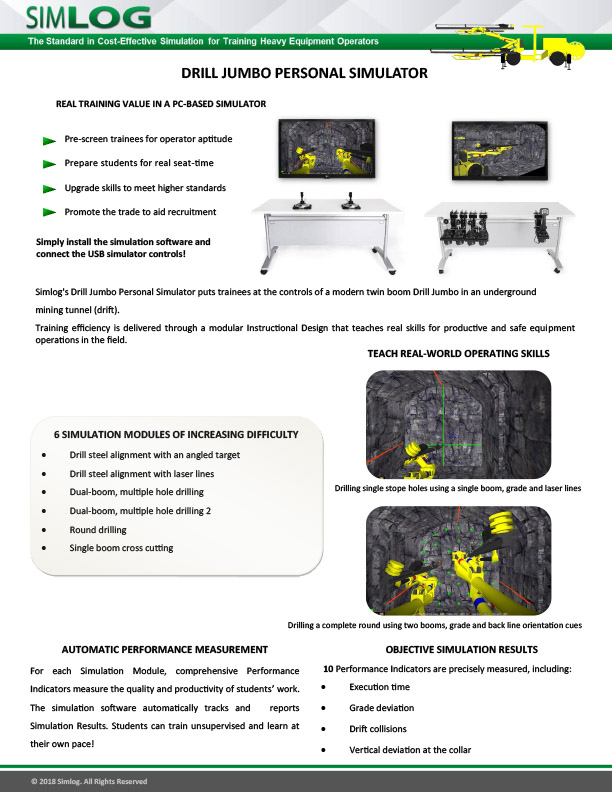

Simlog's Drill Jumbo Personal Simulator puts trainees at the controls of a modern twin boom Drill Jumbo in an underground mining tunnel (drift).

Training efficiency is delivered through a modular Instructional Design that teaches real skills for productive and safe equipment operations in the field.

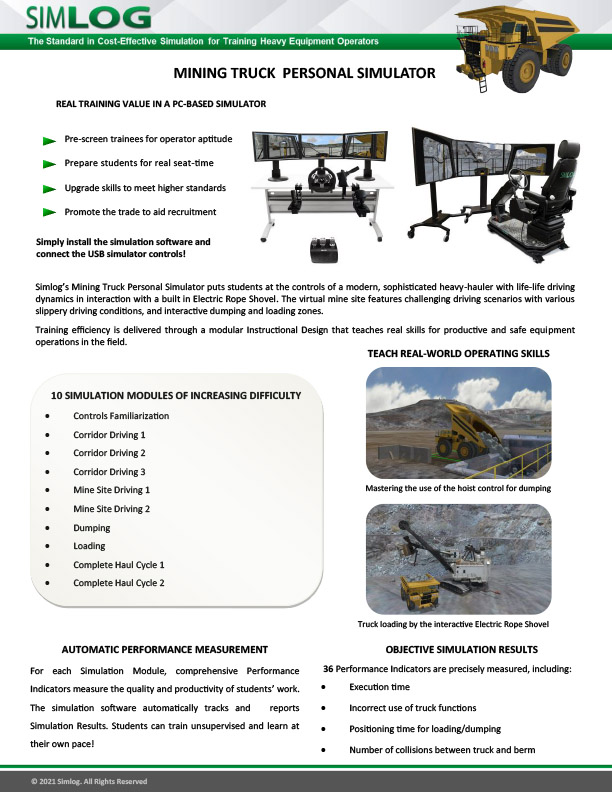

Simlog’s Mining Truck Personal Simulator puts students at the controls of a modern, sophisticated heavy-hauler with life-life driving dynamics in interaction with a built-in Electric Rope Shovel. The virtual mine site features challenging driving scenarios, various slippery driving conditions, and interactive dumping and loading zones.

Training efficiency is delivered through a modular Instructional Design that teaches real skills for productive and safe equipment operations in the field.

Jacob Perkins provides a walkthrough of the features of Bayport Technical's 130-DTU1 Distillation Trainer. This full-sized system includes a chiller, a stripper column, and much more!

See how this fits into your training facility or lab! Get in touch with us today!

Machine Tending Educational Cell integrated with a FANUC Robot and Robodrill together. This cell comes standard with 3-axis milling, air blow-off for chip removal, a fenceless perimeter with safety area scan, and your choice of a Robot or Cobot as the machine tender.

The groundbreaking Skill Boss Logistics trainer just got even more advanced – the Smart Robot Logistics Palletizing Workcell takes what was great about the system and adds another layer of skills crucial to working in a modern, automated logistics environment.

In this video, Amatrol's Director of North American Industry Sales, Mark Goodman, gives an overview of the palletizer system and what it adds to Skill Boss Logistics.

Students can learn how to operate, program, maintain, and troubleshoot a robotic palletizing workcell. They’ll also learn how to power-up and jog an industrial robot workcell using an HMI, operate it both manually and automatically, enter and interpret commands, configure robot vision settings, track robot performance, and ensure safety devices are functioning correctly. It's also possible to add the Mobile Robot Logistics System for even more functionality!

Amatrol's 87-SWPF1V Smart Robot Logistics Palletizing Workcell teaches trainees how to operate, program, maintain, and troubleshoot a robotic palletizing workcell. Students will gain hands-on practice on how to power up and jog an industrial robot workcell using an HMI, operate the workcell both manually and automatically, enter and interpret commands, configure robot vision settings, track robot performance, and ensure safety devices are functioning correctly.

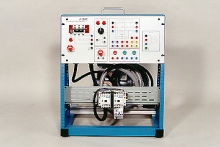

In this video, Regional Manager Jason Everett provides an overview of Amatrol’s Smart Controls Troubleshooting Workstation, including its operation and primary features.

Amatrol’s Smart Controls Troubleshooting Workstation teaches users the hands-on programmable logic controller (PLC) troubleshooting skills they need to excel in today’s jobs that feature various applications with Industry 4.0 technologies.

Pages

-

Item Number:420-000DAC Worldwide’s 1-Phase Motor Control Training System with Manual Starter (420-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial single-phase, manual (across the line) starters.

-

Item Number:273-907DAC Worldwide’s 100A, Single Pole Circuit Breaker Cutaway (273-907) is a detailed and professionally-crafted circuit breaker cutaway that depicts a common DIN-rail-mounted, single-phase industrial breaker. T

-

Item Number:2FG7OnRobot's 2FG7 Finger Gripper is a complete, low-cost, off-the-shelf electric parallel gripper that can be deployed on any major collaborative or light industrial robot within minutes and requires no custom engineering for installation, programming, or maintenance.

-

Item Number:2FGP20The OnRobot 2FGP20 electric gripper offers a wide stroke and customizable arms to easily handle containers that can’t be handled with traditional vacuum grippers. Like all OnRobot electric grippers, the 2FGP20 provides fast, out-of-the-box deployment with intuitive programming.

-

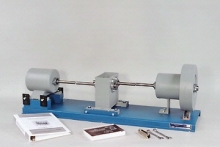

Item Number:206-000Basic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

-

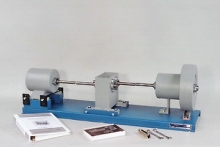

Item Number:206-PACBasic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

-

Item Number:423-000DAC Worlwide’s 3-Phase Motor Control Training System with Magnetic Starter (423-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic starters.

-

Item Number:424-000DAC Worldwide’s 3-Phase Motor Control Training System with Magnetic Starter, Low Voltage Start (424-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic starters.

-

Item Number:422-000DAC Worldwide’s 3-Phase Motor Control Training System with Manual Starter (422-000) is a task-specific, motor control-related training device that allows for skill-building in the operational principles, circuit design, wiring, fault troubleshooting, and application of industrial three-phase, manual motor starters.

-

Item Number:601-000DAC Worldwide’s 3-Variable Process Control Training System (601-000) is a working, large-scale, fluid process system allowing for hands-on training relating to the measurement and control of process variables including level, pressure, and flow.