Kimya PC-FR is a polycarbonate (PC) based material with flame-retardant properties developed specifically for additive manufacturing. It retains the beneficial characteristics of standard polycarbonate such as dimensional stability, high glass transition temperature, and high impact resistance.

Key Attributes

- Flame-resistant material

- Electrical insulator

- Good dimensional stability

- Meets or exceeds the mechanical performance of Stratasys PC material

- Compatible with soluble support

- Meets EN 45545-2 and NFPA 130 standards

- Slice heights: 10

Nylon 12 is a semi-crystalline, FDM® thermoplastic. As with other semi-crystalline materials used in traditional manufacturing processes, special considerations should be implemented to ensure an optimal part is obtained. The information in this document illustrates the following considerations:

- Tip Selection

- Build Modes

- Porosity

- Sacrificial Tower Features

- Build Sheets

- Support Removal

- Annealing

FDM® Nylon 12 filament is the 3D printing equivalent of standard industrial PA12 (polyamide 12) material. A strong engineering thermoplastic that exhibits toughness and high impact strength without being brittle. Its excellent fatigue properties make it a good option for repetitive-flex applications such as snap-fit clips, closures, and press-fit inserts.

Other applications include jigs, fixtures, low-volume production parts, and accurate prototyping of nylon 12 high-volume injection molded parts. FDM Nylon 12 is available in black.

FDM® Nylon 12CF™ is a PA12 (polyamide 12) thermoplastic filament reinforced with chopped carbon fiber, 35% by weight. It has the highest flexural strength of any FDM thermoplastic, resulting in the highest stiffness-to-weight ratio. The combination of high strength, stiffness, and light weight makes it an optimal replacement for heavier metal components in appropriate use cases.

Typical applications include strong, lightweight tooling, functional prototyping and select end-use parts.

FDM Nylon 6™ combines strength and toughness superior to other FDM thermoplastics, for applications that require strong, customized parts and tooling that lasts longer and withstands rigorous functional testing.

Engineered with nylon 6, a popular thermoplastic for manufacturing, this material works with the Fortus 900mc™ to produce durable parts with a clean finish and high break resistance. FDM Nylon 6 is ideal for product manufacturers and development engineers in automotive, aerospace, consumer goods, and industrial manufacturing.

PC-ABS is a blend of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) thermoplastics. The result is an FDM filament that exhibits optimal characteristics of each – excellent strength, high toughness and heat resistance, and good flexural strength. Choose PC-ABS when you need the strength of PC but the impact resistance of ABS.

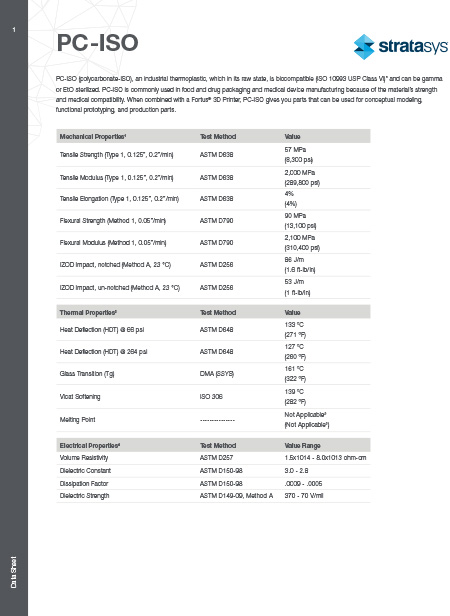

PC-ABS is suitable for various applications that include prototyping, tooling, and low-volume production. Available colors are black, white, and red.PC-ISO (polycarbonate-ISO), an industrial thermoplastic, is biocompatible in its raw state (ISO 10993 USP Class VI)* and can be gamma or EtO sterilized. PC-ISO is commonly used in food and drug packaging and medical device manufacturing because of the material’s strength and medical compatibility. When combined with a Fortus® 3D Printer, PC-ISO gives you parts that can be used for conceptual modeling, functional prototyping, and production parts.

Material properties are an important consideration when evaluating additive manufacturing for advanced applications such as production runs of end-use parts. Since these products will be in service for extended periods and in varying conditions, qualifying the properties beyond published specifications is imperative.

Pages

-

SACA’s Specialist certifications certify Industry 4.0 technical skills in operations, troubleshooting, programming, maintenance, and systems integration. Each certification is keyed to a skilled occupation.

-

The purpose of the Certified Logistics Technician (CLT) program is to recognize through certification individuals who demonstrate mastery of the core competencies of material handling at the front-line (entry-level through front-line supervisor) through successful completion of the certification assessments.

-

Item Number:CPT / CPT+ / CPT 4.0The purpose of the Certified Production Technician (CPT) ® 4.0 certification program is to recognize through certification, individuals who demonstrate mastery of the foundational, core competencies of advanced manufacturing production at the entry-level to front-line supervisor through successful completion of the certification assessments.

-

Item Number:CT-SCAMSSC’s Certified Technician in Supply Chain Automation (CT-SCA) logistics certification enables both students and incumbent workers to gain the skills needed to meet the definition of a supply chain automation technician established by the National Science Foundation-funded National Center for Supply Chain Automation: a technician who installs, operates, supports, upgrades or maintains the automated material handling equipment and systems which support the supply chain.

-

Item Number:223-000DAC Worldwide’s Chain Drive Training System (223-000) is a heavy-duty learning aide that allows for in-depth training in industrial chain drives, heavy/silent chains, and sprocket set usage.

-

Item Number:223-PACDAC Worldwide’s Chain Drive Training System Plus (223-PAC) is a heavy-duty learning aide that allows for in-depth training in industrial chain drives, heavy/silent chains, and sprocket set usage.

-

Item Number:838-PACDAC Worldwide’s Chain Sample Board (838-PAC) is an introductory hands-on teaching aid, designed to supplement courses in chain selection and maintenance. It includes samples of eight (8) industrial-quality chains for users to learn to identify.

-

Hard Hat VR's Chemical Spill Cleanup simulation is ideal for future employees or supervisors who will work in or visit warehouses or factories. The primary goal of this course is to teach individuals safe work procedures for chemical spill cleanup.

-

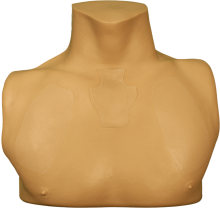

Item Number:TFX-T-CT-1The TacMed Simulation Chest Trainer is a ruggedized partial upper torso medical simulator that helps trainees during the crawl phase of training to treat patients requiring needle decompression and intraosseous (I/O) infusion. Students learn to locate realistic anatomic landmarks to execute critical patient treatment without relying on marked indicators. The unit functions as a stand-alone skills station with multiple training sites that allow for multiple uses with cost-effective replacement components.

-

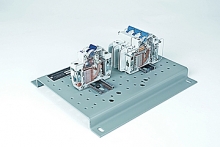

Item Number:273-906DAC Worldwide’s Circuit Breaker Cutaway Set (273-906) is a detailed, sectioned, professionally-crafted set of two circuit breaker cutaways that unveils the internal construction and operating mechanism of commonly-encountered single-pole and three-pole circuit breakers found within industrial and commercial electrical systems for circuit protection.