Solar energy is being used in a broad range of applications across industry and residences alike. From heating water for home use to creating utility scale electricity – solar energy application is growing, as is the need for solar concepts training. Understanding the basics of how we can harness solar energy is essential for technicians, engineers, installers, designers, builders, and others who want to apply solar technology either professionally or personally.

Amatrol’s Solar Concepts Learning System (950-SC1) introduces learners to a broad range of basic concepts in solar energy and technology. Photovoltaic and thermal solar systems are introduced to students. They learn how to translate location, sun, and technology into practical applications. The Solar Concepts training acts as a foundation for students in solar technology. Solar Concepts includes student curriculum in a highly-interactive, multimedia format.

Amatrol’s Steam System Training System (950-SH1) introduces learners to the operation, installation, maintenance, and repair of steam systems and their application in paper mills, commercial and residential settings, power companies, and even nuclear submarines. Amatrol’s exceptionally thorough curriculum covers a comprehensive range of steam system topics, including both practical applications such as how to operate a boiler and theoretical knowledge like the coefficient of volume and thermal expansion.

The 950-SH1 includes an electric boiler, blowdown separator, condensate feedwater system, heat exchanger, strainer, and steam trap. This learning system also comes with a welded steel mobile workstation (32-in W x 82-in H x 92- in L) with 4” square welded steel tubing and heavy duty casters. Amatrol supplies these industrial-grade, top-flight components in order to give the learner an opportunity to work with real-world mechanisms and gain experience they would normally only acquire on the job.

Amatrol’s Solar PV Installation Learning System consists of a mobile workstation with real solar PV components, including a PV array, micro-inverter, combiner box, communications gateway, charge controller, and remote meter. To make installation training more efficient, tools and consumables, such as a clamp meter, digital meter, wire, and conduit, are stored conveniently on the workstation.

Amatrol’s Solar PV Troubleshooting Learning System features a wide variety of industry-standard solar PV equipment to teach relevant hands-on skills. For example, the 950-SPT1 includes a mobile workstation with a combiner box, MPPT charge controller, micro inverter, grid interactive inverter, programmer, and communications gateway and hub.

For a complete solar PV troubleshooting training experience, the required Solar PV Array Station (95-SPA1) adds multiple solar panels to enable students and workers to duplicate realistic situations with both series and parallel connections. The mobile array station allows instructors to take advantage of sunny days without having to move the entire trainer. It is also equipped with a sun simulator to enable indoor use.

The growing interest in alternative energy and renewable resources has created a shortage of qualified solar thermal technicians throughout the green energy sector. So what are some of the essential skills that solar thermal technicians need to succeed?

Solar thermal technicians need basic knowledge and hands-on skills in a variety of foundational technologies, such as electrical, electronics, and fluid power, as well as advanced abilities related directly to the latest solar thermal technologies. Amatrol’s Solar Thermal Troubleshooting – Closed-Loop Learning System (950-STCL1) teaches a range of solar thermal troubleshooting skills for closed-loop systems through a unique combination of eLearning curriculum and hands-on experience with real industrial solar thermal components.

The 950-STF1 Solar Thermal Installation training system teaches students the installation and commissioning of closed loop and open loop solar thermal systems for commercial and residential applications. Students will learn how to install systems by selecting, preparing, mounting and connecting solar thermal components using copper tubing, PVC piping, and electrical wiring. Students will create and commission complete working systems, just as they would do on the job.

The Solar Thermal Installation training system includes a mobile workstation with solar thermal components; solar thermal collectors; PC-based interactive, multimedia student curriculum; and teacher’s guide. The mobile workstation is equipped with shadow boards for component storage, a benchtop worksurface and vise for tubing preparation, and mounting surface for assembly of solar thermal systems.

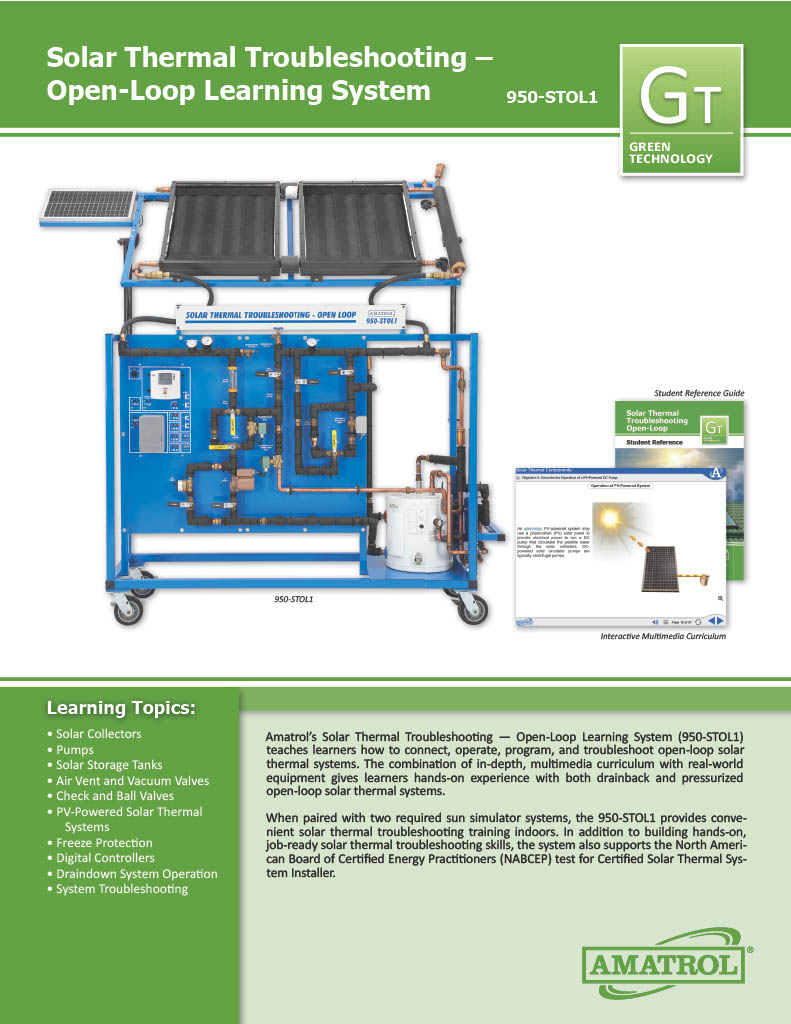

Amatrol’s Solar Thermal Troubleshooting – Open-Loop Learning System features a wide variety of industry-standard solar thermal equipment to teach relevant hands-on skills. For example, the 950-STOL1 includes a mobile workstation with a digital differential controller; AC and DC centrifugal pumps; temperature probes; check valves; flow meters; relief valves; vacation bypass; tempering valves; solar storage tank; multiple component circuit panels; photovoltaic panel; and two solar collectors.

Learners using Amatrol’s eLearning will find that its comprehensive, detailed curriculum teaches both the foundational knowledge and practical hands-on skills they need to troubleshoot both draindown and pressurized open-loop solar thermal systems. It will also help students and workers prepare for solar certifications from the North American Board of Certified Energy Practitioners (NABCEP), the premier solar technology certification organization.

Wind turbine electric hubs present unique operational and maintenance challenges. Wind turbine technicians must pinpoint and resolve a wide variety of situations where the hub is key, especially in changing load conditions. The turbine electric hub troubleshooting and problem solving skills have to be excellent to keep wind turbines operational.

Amatrol’s Turbine Electric Hub Troubleshooting Learning System (950-TEH1) teaches learners adaptive skills for wind turbine operation, adjustment, and troubleshooting in a wide variety of situations. Turbine Electric Hub Troubleshooting training system allows learners to develop and practice component, subsystem, and system level skills. It is fully functional like a utility-scale turbine electric hub. Turbine Electric Hub Troubleshooting includes Amatrol’s unique electronic fault insertion system, which allows instructors to electronically create realistic hub problems and then track the learner’s progress in solving the problem. Additionally, Turbine Electric Hub Troubleshooting will connect to the Turbine Nacelle Learning System (950-TNC1) and the Turbine Generator Control Troubleshooting Learning System (950-TGC1) to create a complete wind turbine learning experience.

Turbine Electric Hub Troubleshooting is an effective training platform for wind turbine technicians. This system includes a mobile workstation, blade simulator with 3-axis servo system, pitch control unit, emergency power unit, blade simulator, pitch control software, and fault insertion system.

The generator control system is the heart of a utility-scale wind turbine, converting mechanical rotation of the hub into clean, 3-phase power that synchronizes with the utility grid. Keeping these turbines operational and well maintained requires a specialized skill set, and wind turbine technicians possess these skills. They know how to service, operate, and troubleshoot the generator control system, which includes the generator, rectifier, generator control unit, power distribution panel, pad mounted transformer, and generator control software.

Amatrol’s Wind Turbine Generator Control Troubleshooting Learning System (950-TGC1) allows learners to gain adaptive skills for generator system operation, adjustment, and troubleshooting in a wide variety of situations. It helps learners to develop and practice both wind turbine component and system level skills and gives them the classroom instruction and hands-on experience that they need to succeed in this emerging and growing field. Wind Turbine Generator Control Troubleshooting also includes Amatrol’s unique electronic fault insertion system, which lets learners gain hands-on experience with the troubleshooting of realistic generator control problems, as well as receive automatic feedback on their progress.

Furthermore, Turbine Generator Control Troubleshooting connects to Amatrol’s Nacelle and Hub workstations to create a comprehensive wind turbine learning laboratory.

Amatrol’s Turbine Nacelle Troubleshooting Learning System (950-TNC1) teaches learners the unique skills required to operate, adjust, troubleshoot, and maintain wind turbine nacelle systems. The system replicates a fully-functional, utility-scale nacelle, allowing learners to develop and practice component-, subsystem-, and system-level skills.

The Wind Turbine Nacelle training and troubleshooting system also features FaultPro, Amatrol’s exclusive computer-based fault insertion system. FaultPro allows an instructor to electronically insert realistic nacelle problems into the system and then track a learner’s progress in troubleshooting and solving the problems. The wind turbine nacelle troubleshooting system can also be connected to the Turbine Electric Hub Learning System (950-TEH1) and the Turbine Generator Control Learning System (950-TGC1) to create a comprehensive wind turbine learning experience.

Pages

-

Item Number:T7082Amatrol’s Air Conditioning/Heat Pump Operations Learning System (T7082) features industry-standard heating and cooling components that form a working heat pump trainer, ac trainer and refrigeration system.

-

Item Number:T7082AAmatrol’s Air Conditioning / Heat Pump Troubleshooting Trainer (T7082A) teaches valuable HVAC troubleshooting skills on a hands-on learning system that performs heat pump, air conditioning and refrigeration operation.

-

Amatrol’s FaultPro computer-based fault insertion software is the industry’s only electronic troubleshooting training system. FaultPro allows instructors to instantly set and tailor faults to test a student’s weaknesses and turn them into strengths.

-

Item Number:95-MSB1Amatrol's Skill Boss Manufacturing is a hands-on training and assessment tool for CPT+ certification that meets MSSC standards easily integrates into manufacturing programs.

-

Item Number:87-TMSTrain future technicians with Amatrol’s Tabletop Smart Factory and Cobot-Integrated Mechatronics systems—hands-on, compact training with real industrial components, Rockwell Automation integration, and FANUC CRX collaborative robotics.

-

Each Advanced Manufacturing topic incorporates the skill development needed for modern industry. From operation to complex troubleshooting, Amatrol’s learning systems deliver job-ready skills.

-

Item Number:T7045Amatrol’s Basic Refrigeration training system (T7045) offers hands-on learning of a working refrigeration system in a compact tabletop unit.

-

Item Number:T7200Amatrol’s Combined Refrigeration Installation Learning System (T7200), an ideal training tool for HVAC/R technicians, offers a comprehensive hands-on workstation and interactive multimedia curriculum to teach installing electrical and mechanical refrigeration/air conditioning components in residential or light commercial applications.

-

Item Number:T7083Amatrol's Environmental Applications Learning System (T7083), an expansion for the Air Conditioning / Heat Pump Operations Learning System (T7082) or the Troubleshooting Learning System (T7082A), is a model of a house complete with insulation, siding, shingles, and a window.

-

Item Number:CRX 5iA | CRX-10iA | CRX-10iA/L | CRX 20iA/L | CRX 25iAExperience the all-new CRX Series, FANUC's latest collaborative robot designed to make installation and programming your cobots easier than ever before.