OnRobot Sander

- Easy to deploy and program right out of the box for sanding, buffing and polishing

- Complete package includes everything needed for immediate use on a range of parts and materials

- Fast, automated sanding Grit Changer reduces downtime and labor

- Electric tool (no compressed air) boosts efficiency and control

Why OnRobot Sander?

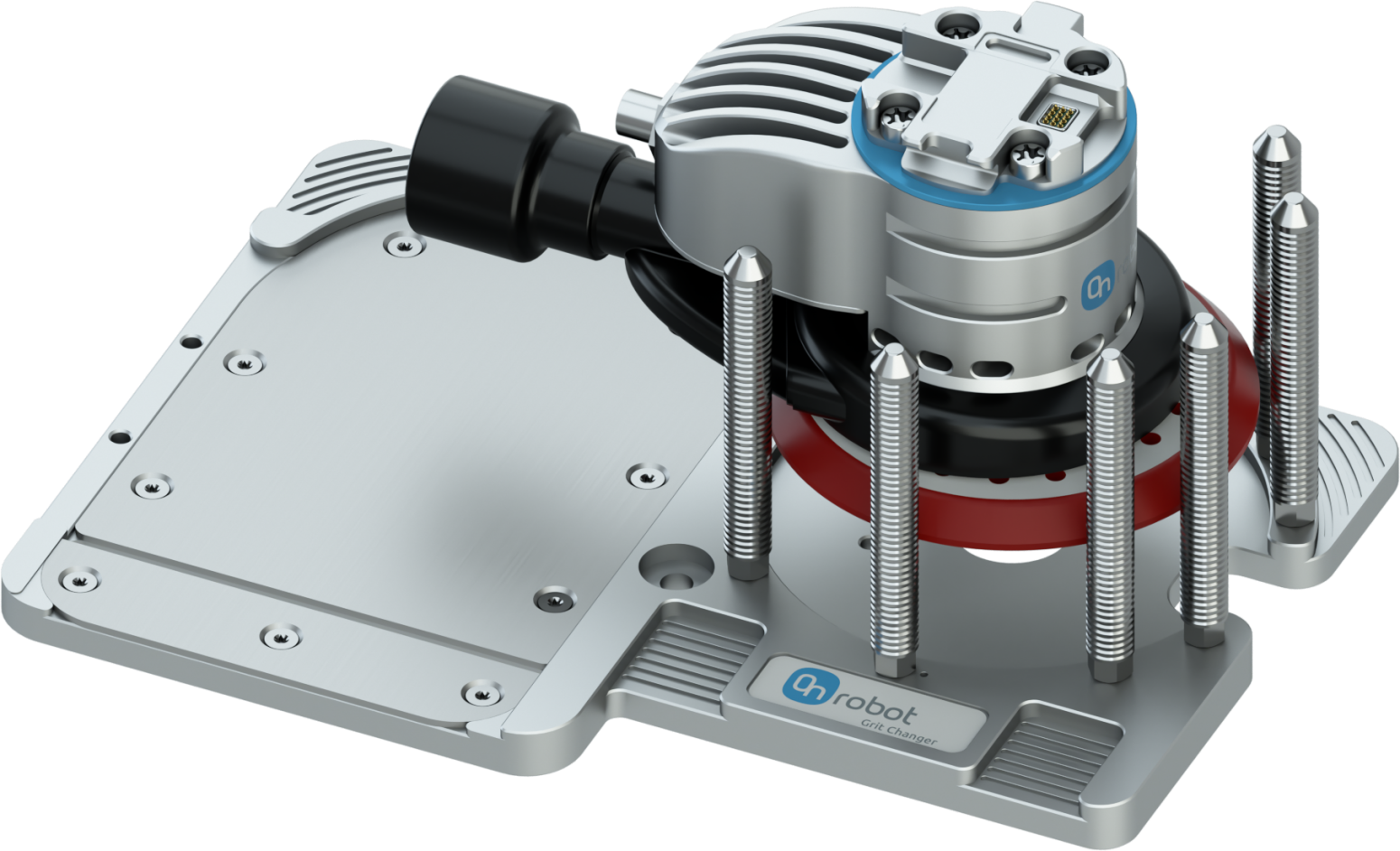

Complete electric random orbital sander for almost any automated surface finishing application, from sanding and buffing to polishing and cleaning. The Sander is available with everything you need to get started right away, and operates without external air supply, for no additional costs or complexity, and none of the dust or noise generated by traditional air sanders.

REDUCED COMPLEXITY

Precise force control and intelligent error detection.

QUALITY AND CONSISTENCY

Automate multiple screwdriving processes with a fast, out-of-the-box setup and deployment.

EMPLOYEE SAFETY

Fast and easy deployment with One System setup.

Advantages and Features

The OnRobot Sander comes with everything you need to get started right away: plug-and-play sanding tool, a variety of standard sanding and polishing discs, easy-to-use software, and optional automated Grit Changer and force torque sensor. What you don’t need is a noisy and expensive air compressor for this economical electric sander.

Use this flexible tool for a wide range of part geometries and materials to get greater consistency, higher finish quality, and lower scrap rate. You’ll reduce workplace dust due to the use of standard 3M clean sandpaper discs and reduce the risk of worker injury from the vibration of manual sanders.

Programming for simple surface treatments can be completed with basic robot knowledge—no additional training required. The sanding tool’s software is automatically integrated into the robot’s teach pendant, but a manual “save position” button on the tool allows for even easier waypoint settings, without using the teach pendant. The Sander software comes with different path planning options - path from handguide, shape and points, and allows users to adjust rotation speed, optimizing cycle time and consistency.

All of the advanced features of the OnRobot Sander are supported on Universal Robots arms, but the tool is easily integrated with any major robot brand.

FAST, EASY SETUP AND CHANGES

Out-of-the-box deployment with the ability to quickly program and re-program material removal and finishing tasks.

FLEXIBLE FOR WIDE RANGE OF MATERIALS AND GEOMETRIES

Replaceable standard sanding discs and easy adjustment of tool's rotation speed ensures high quality surface finishing.

FACILITATES COMPLIANCE WITH LOCAL HEALTH AND SAFETY REGULATIONS

Reduces risk of workplace injuries caused by high vibration in hand tools and fine dust.

COMPLETE WITH EVERYTHING NEEDED TO GET STARTED

Complete solution includes sanding tool, standard pads and grits, and optional automated Grit Changer and force torque sensor.

NO COMPRESSED AIR REQUIRED

Powerful and durable electric sander does not require compressed air, significantly reducing high running and maintenance costs.

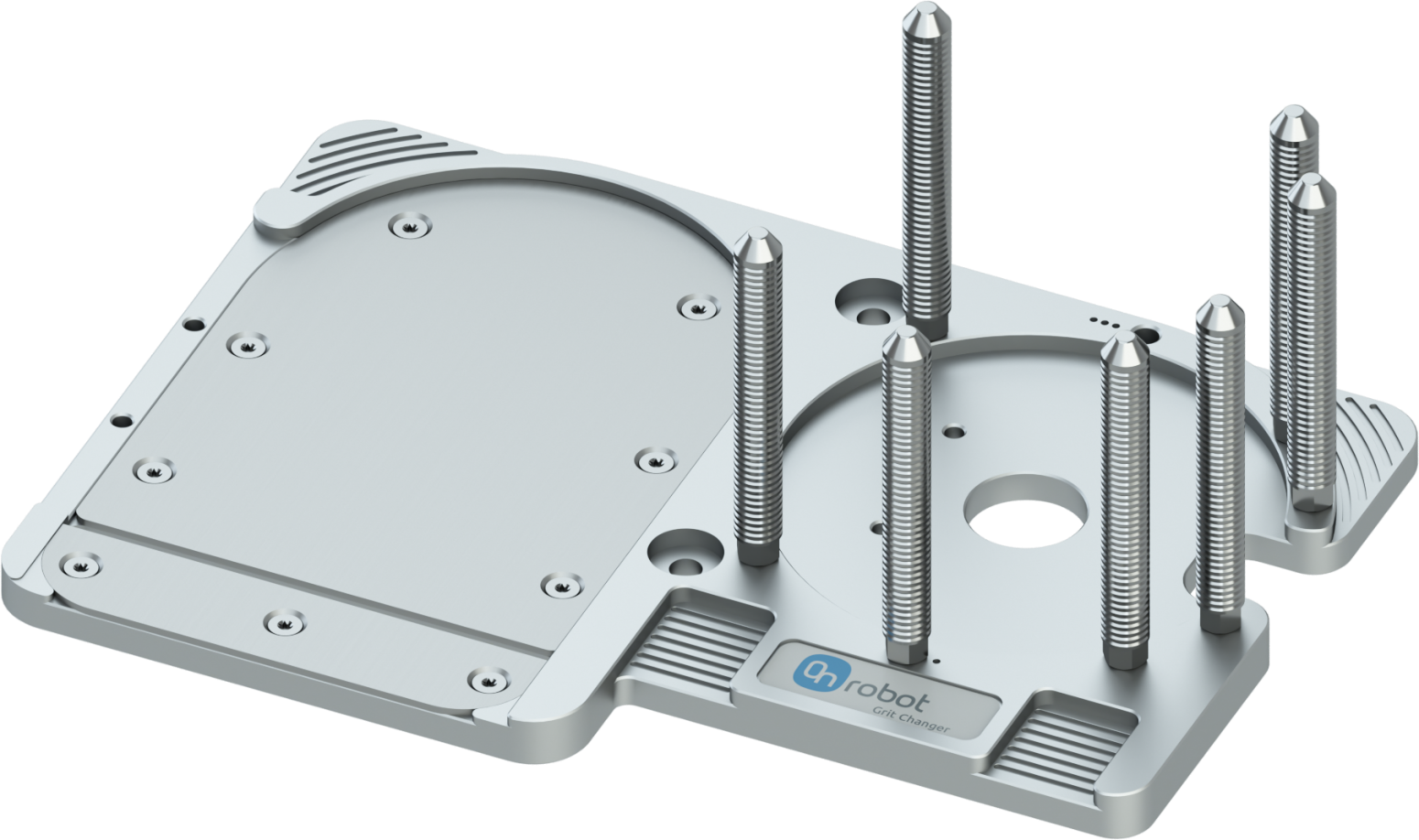

OPTIONAL GRIT CHANGER AVAILABLE

Enables automatic switching between different sanding discs without the need for operator intervention.

Applications

Material Removal

Material Removal

Flexible sanding tool can be used for different part geometries and materials to get greater consistency, higher finish quality, and lower scrap rate. It’s ideal for sanding and polishing applications.