Machine Tending Education Cell with CNC Simulator

MTEC-SIM FEATURES

- Students learn robot to CNC communication in a classroom environment

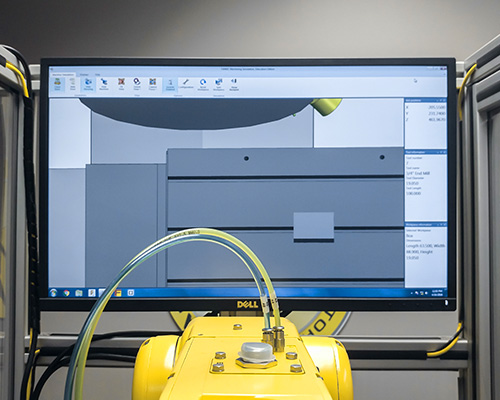

- Real CNC programming with simulated cutting using Fanuc CNC Educational Simulator

- Mill and Lathe in one compact cell

- Fanuc Certified Education CNC Training

- Fully guarded robot motion for safety

- iRVision training for error-proofing and guidance

- 120 VAC power connection with built in air compressor

- Fits through standard door

- Builtiin lockable tool box for convenience

Training Areas: Robot, iRVision 2D, FANUC CNC

Training Levels: I, II, NIMS

Education for Real World Advanced Manufacturing

The MTEC-SIM is a feature-packed robot and CNC training cell for multi-level FANUC certifications.

- Qualifies for FANUC educational CERT program

- Integrated system with FANUC Robot and FANUC CNC Simulator

- Utilizes a FANUC LR Mate 200iD/4S

- Fits through a standard 36” doorway

- See and hear your part get machined

This machine comes ready for mill and lathe operation with the robot moving a blank from a pick location to a simulated mill vice or lathe chuck all in one compact cell. The student can see the machine tool come to life on the monitor, hear the tools cutting, and crash the machine (virtually). They can program the robot to load and unload the part. This is the perfect introduction of robot to machine communications.

What can I do with an MTEC-SIM?

Curriculum

FANUC Robotics Courses:

- Handling Tool Operation and Programming

- Handling PRO

- iR Vision 2D

- Advanced TPP

- DCS

CNC Concepts Courses:

- Machining, Programming, Setup, and Operation

- Turning, Programming, Setup, and Operation

- FANUC Simulator Exercises

APT Integration Courses:

- Intermediate Concepts: Maintenance and Troubleshooting of Industrial Equipment

- Introduction to Industrial Automation and Integration

- Basic Integration Labs: PLC, HMI, Robot, Ancillary Components

- Robot to CNC: Integration Fundamentals and Labs

- Safety Systems and Standards Design and Application

Career Paths and Certifications

Career Paths:

- FANUC Robot Technician

- FANUC Robot Operator – Material Handling

- Robot Integration

- CNC Operator

- CNC Machine Technician

- Maintenance Technician

- PLC/Controls Technician

- Industrial Controls Integrator

NOCTI Certifications:

- FCR-01 (FANUC Certified Operator 1) – Written

- FCR-02 (FANUC Certified Operator 2) – Performance

- FCR-T1 (FANUC Certified Robot Technician 2)

NIMS Certifications:

- CNC Mill Programming Setup and Operation

- CNC Mill Operations

Software

Material Handling (MH) CERT Instructor Training and Tool Kit

- (1) online seat to take CERT Cart Safety Features web course

- (1) online seat to take Robot Operations web course

- (1) online seat to take HandlingTool or ArcTool Operation and Programming web course

- (1) online seat to take HandlingPRO or WeldPRO web course

- (1) seat to take a live HandlingTool or ArcTool Operation and Programming class at a FANUC facility

- (1) ROBOGUIDE Simulation Software license

- (1) FANUC Robot Operations Manual

- (1) FANUC HandlingTool or ArcTool Operations and Programming Manual

- (1) FANUC HandlingPRO (ROBOGUIDE Simulation) Manual

Material Handling (MH) CERT School Comprehensive Educational Package

- (25) online seat to take Robot Operations web course

- (25) online seat to take HandlingTool or ArcTool Operation and Programming web course

- (25) online seat to take HandlingPRO or WeldPRO web course

- (25) ROBOGUIDE Simulation Software license

Features

- Modular Robot Cart

- Welded Steel Construction

- Fits through standard doorway

- Single 2 jaw EOAT for mill blank and lathe blank

- Fold up worktable for laptop, test book, etc.

- Safety interlocked access door to robot work area

- Three color beacon operation indicator light

- Swivel casters with brakes and rotation lock

- Wireless keyboard and mouse

- FANUC R30iB Plus Robot Controller

- FANUC LR Mate 200iD 4S 6 axis robot

- 2D iRVision Optional

FANUC’s new R-30iB Plus Robot Controllers feature the new iPendant with enhanced screen resolution and processing capability. The new user interface, iHMI, can display guides for setup and programming, as well as tutorials from the main home page which has a design common to FANUC CNCs, enabling easier use of robots. Using the programming guide, even first-time robot users can create a program for a simple handling task and execute it in just 30 minutes! Easier usage also improves efficiency by facilitating system setup and maintenance.

The CNC education simulator is designed specifically for educational purposes, ensuring affordable access to the latest FANUC CNC platform in a compact and portable package, easily integrated into any classroom.

- Switchable mill and lathe system in one simulator

- 3 Axis milling / 2 axis turning system + 1 spindle

- Conversational programming and 3D simulation (MGi)

- Inch / metric switchable

- 32 Tool offset pairs

- Work piece coordinates G52 – G59 + 48 additional on mill

- 10.4” Color LCD

- Full QWERTY keyboard