Training the Next Generation for Robotic Welding

Essential Skills and Solutions for Educators

Robotic welding is revolutionizing the manufacturing industry, improving efficiency, precision, and safety on production lines. As automation continues to reshape industries, demand for professionals trained in robotic welding is surging. For educators and training institutions, equipping students with the necessary skills in this field is essential to meet the growing workforce demands.

What is Robotic Welding?

Robotic welding involves the use of programmable machines to automate the welding process. These robots are designed to perform a range of welding techniques, such as arc welding, spot welding, and laser welding, with greater accuracy and consistency than manual welders. Robots are particularly effective in handling repetitive tasks, improving production speed, and minimizing the risk of human error.

Robotic welding is widely used in industries like automotive, aerospace, heavy equipment manufacturing, and more. With advancements in automation technology, companies are increasingly relying on welding robots to produce high-quality, precise welds in large-scale production environments.

Where and When is Robotic Welding Used?

Robotic welding is commonly deployed in high-volume production environments, particularly where precision and efficiency are critical. For example:

- Automotive Industry: Welding robots are extensively used in vehicle assembly lines to weld body parts, frames, and chassis with precision.

- Aerospace Industry: In aerospace manufacturing, robotic welding ensures the production of highly durable and consistent welds for aircraft components.

- Heavy Equipment Manufacturing: Robotic welding is used to weld large components and equipment with intricate welding requirements.

These industries benefit from reduced production times, improved safety for workers, and lower operational costs. The technology is also expanding into other sectors like renewable energy and construction, making robotic welding a versatile and integral tool in modern manufacturing.

Why is Robotic Welding in High Demand?

With industries embracing automation, the demand for skilled robotic welding technicians is growing rapidly. According to industry reports, the global market for industrial robotics is expected to continue its growth trajectory, driven by the need for efficiency, cost reduction, and precision in manufacturing processes. However, there is a significant skills gap that must be addressed to meet this demand.

For educators and training institutions, this presents a unique opportunity. Equipping students with the technical knowledge and hands-on skills to operate and maintain welding robots will prepare them for lucrative careers in advanced manufacturing.

APT Manufacturing Solutions: Comprehensive Training for Robotic Welding

We partner with APT Manufacturing Solutions to provide cutting-edge training solutions that equip students and trainees with the skills needed to excel in robotic welding. Our training programs are designed to meet the needs of educators who aim to deliver a curriculum that aligns with industry standards and employer demands.

Key Features of APT Robotic Welding Training Solutions:

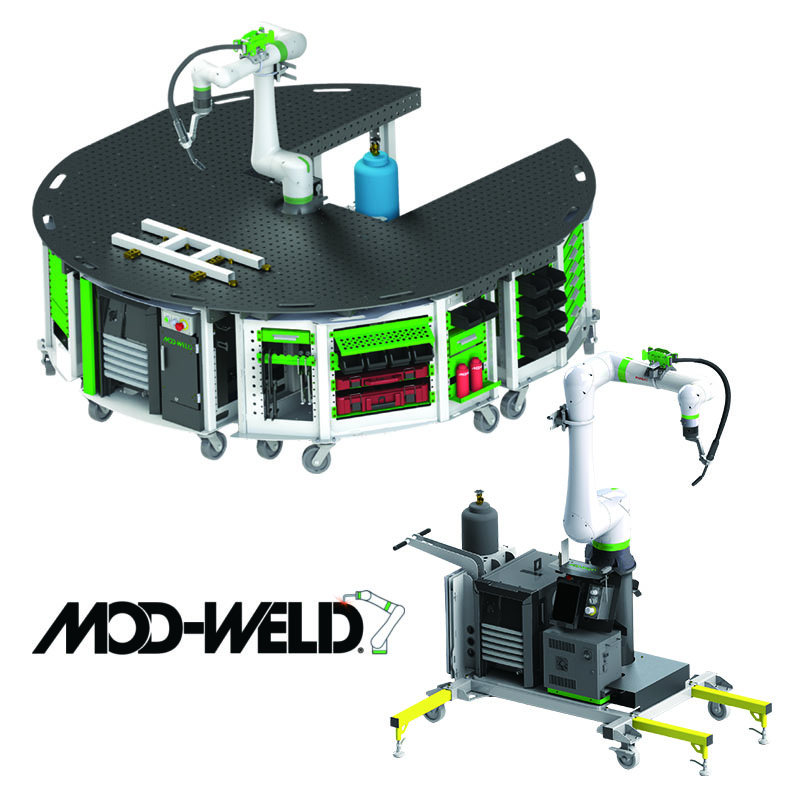

- Hands-On Learning: APT's trainers are designed to simulate real-world welding environments, allowing students to practice and refine their skills in a controlled setting.

- Industry-Grade Equipment: Our training solutions utilize the same robotic welding equipment and software used by leading manufacturers, ensuring students gain practical, relevant experience.

- Customizable Curriculum: We offer flexible training modules that can be integrated into existing welding programs, making it easier for institutions to adopt robotic welding instruction.

- Certifications: Our solutions are aligned with industry-recognized certifications, such as those from the Smart Automation Certification Alliance (SACA), providing students with credentials that validate their skills.

- Customizable Curriculum: We offer flexible training modules that can be integrated into existing welding programs, making it easier for institutions to adopt robotic welding instruction.

Preparing the Future Workforce

As the demand for robotic welding professionals grows, educators and training institutions must adapt to ensure their students are ready to meet industry needs. At Tech-Labs, we are committed to supporting this mission by offering APT Manufacturing’s innovative training solutions. By incorporating robotic welding into your curriculum, you can provide students with the skills and certifications they need to thrive in today’s automated manufacturing landscape.

If you’re ready to elevate your training programs and help bridge the skills gap in robotic welding, contact us to learn more about how APT Manufacturing’s solutions can benefit your institution.