InterPRO Helps Distek Serve More Customers with 3D Printed Adapters

InterPRO Helps Distek Serve More Customers with 3D Printed Adapters

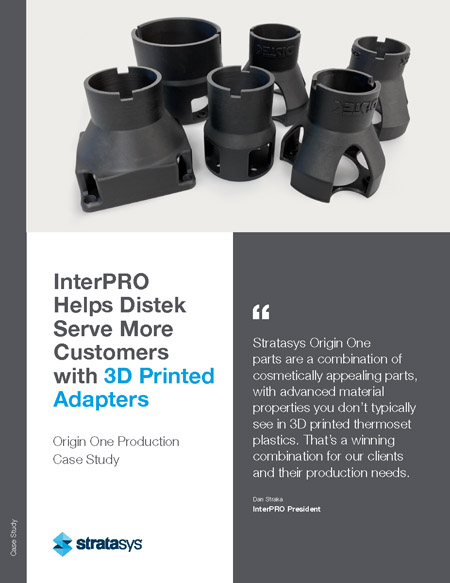

InterPRO Additive Manufacturing Group, a service bureau, started as a 3D printing prototyping company and is seeing growth in production applications due to advancements in 3D print technology and materials. InterPRO’s client Distek, a leading manufacturer of laboratory testing instruments for the pharmaceutical and biotechnology industries, asked InterPRO to help them manufacture a motor adapter that would allow prospective customers to use Distek’s technology with customers’ existing motors. InterPRO used Stratasys’ Origin® One’s next-generation 3D printing hardware and software to print parts compatible with Distek’s bioreactor and their client’s devices. The parts had injection molded-like strength, consistency, and durability. The surface finish had an impressive, consumer-grade look and feel.

Distek’s challenge was to produce a motor adapter compatible with their proprietary bioreactor and their clients’ motors. However, the adapter design wasn’t easily manufacturable by CNC machining, injection molding, or even cast urethane. In addition, the company needed a fast turnaround to meet immediate customer needs for various adapter sizes in low volumes. High up-front tooling costs, long lead times, and low-volume demand ruled out traditional methods. As a result, InterPRO turned to 3D printing as a possible solution.