Omaha Public Schools Implement Simlog's Forklift Personal Simulators

How Omaha Public Schools Implemented Simlog's Forklift Personal Simulators for OSHA Operator Certification in a Transportation, Distribution and Logistics Program

Bryan High School is located in Bellevue, Nebraska, a city 8 miles south of Omaha, and it is part of the Omaha Public Schools (OPS) school district. The school serves grades 9 to 12 and has built its curriculum around sixteen career clusters intended to prepare students to complete high school, to begin work on a post-secondary degree, or to enter the workforce. Bryan High School has a population of just over 2,000 students and 120 staff members.

The Transportation, Distribution and Logistics (TDL) Academy is a four-year program of study within Bryan High School for students interested in careers in transportation, distribution or supply chain management. The program uses a “Pocket Academy” approach, whereby technical instruction is integrated with academic content. Teachers from other subject areas work with the Academy instructors to integrate curriculum and concepts into core academic subjects.

To give students the real-world experience needed to meet new career-ready requirements, Bryan High School developed a partnership with First Book - a non-profit book bank that provides books to children in need. Bryan High School is one of sixteen secondary school distribution centers for First Book. One of the objectives of this partnership is to provide TDL students with industry recognized OSHA (Occupational Safety and Health Administration) and forklift operator certifications.

The Need for Forklift Simulation

Simlog's Forklift Personal Simulator was first identified by Jim Musil, OPS Supervisor for Industrial Technology, and Joshua Hogrefe, TDL Instructor at Bryan High School, at ACTE Career Tech Visions in Las Vegas in 2013. In 2014, faced with increased enrollment numbers, and having only one real forklift, OPS purchased two Forklift Personal Simulators for Bryan High School through Simlog’s educational systems reseller in Nebraska, Moss Educational and Industrial Training Solutions .

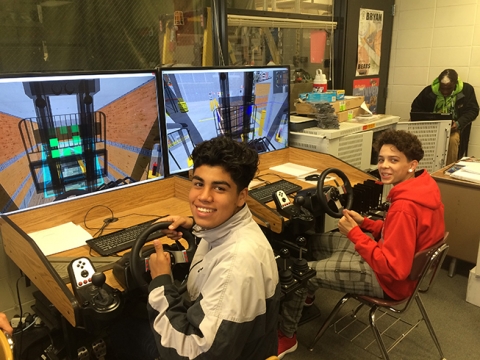

Each Forklift simulator station is set up on a desktop PC equipped with a big screen display and speakers, all supplied by Moss as a turnkey setup. Each simulator station uses table-top mounted simulator controls that include four industrial strength USB-ready Replica Controls Forklift Levers, and a “Logitech G27 Racing Wheel” consisting of a steering wheel, a three-pedal unit and a gear shifter.

Joshua Hogrefe was in charge of incorporating the Forklift simulator lab into the curriculum. Mr. Hogrefe teaches the freshman through senior classes of the TDL program (grades 9 through 12). He is an OSHA certified instructor through the Midwest Safety Council in Omaha, and uses OSHA curriculum provided by that same organization.

“The simulators have been an excellent addition to the program” explains Hogrefe. “In Nebraska, you cannot have a forklift operator license until you are 18 years of age. To keep the kids going, I train them on the Forklift simulators, and when they are ready to go on to the real forklift, I have nothing to worry about.”

“In comparison with the previous year when none of the kids were on the simulators,” continues Hogrefe, “my anxiety is now gone, and the kids’ confidence has increased immensely.”

Since the acquisition of Simlog’s Forklift Personal Simulators in April 2014, in preparation for the 2014 – 2015 school year, Bryan High School and the TDL program have been able to deliver over 1,000 hours of total simulator-based training to 120 students throughout the school year, for students in grades 9 to 12.

A Self-Managed Class

Simulator-based training begins in the students' freshman year (grade 9) and continues through their senior year (grade 12). During the first two years when the goal is career awareness, the students receive an average of 12 hours of simulator training divided into two to three 15 minute time slots per student per week. There are a total of 90 students in the grades 9 and 10 classes (approximately 45 students per class).

In the sophomore (grade 11) and senior (grade 12) years, students use the simulators to prepare for seat time at the controls of the real forklift. These Advanced classes have fewer students, so the amount of simulator time per teaching period increases to 30 minutes. There are 20 students in the grade 11 class and 10 students in the grade 12 class.

The simulators have a built-in instructional design that teaches real forklift operator skills and best practices for being safe at the controls. Skills development is segmented into a series of modular tasks that be-come progressively more difficult. Students can self-start on the simulators, learn at their own pace, and can self-manage their training under a tight class schedule.

"The way I set it up, the kids self-manage their use of the simulators,” explains Hogrefe. “Since there are just 2 simulator stations, most students are at their desks during the teaching period for classroom instruction, while others rotate their time on the simulators. Students work at their own pace so that they can become more confident about their abilities before they move on.”

“I didn’t want to set a timeline where students have to meet goals by a specific date, or we are moving on,” continues Hogrefe. “I want the kids that might be a little slower to have the chance to keep working at it over and over again until they get it down.”

To decide if his grade 12 students are ready for the real forklift, Mr. Hogrefe relies on the comprehensive Performance Indicators that are automatically measured by the Forklift simulation software, and saved in the Simulation Manager database, as the students work on each Simulation Module. Mr. Hogrefe places the focus mainly on safety, and requires that for each Simulation Module, the student completes a session of five consecutive trials (exercises) with no per-trial errors.

Forklift Operator Certification and Outcomes

The 2014-2015 school year saw the first senior class of 10 students graduate from the new operator training curriculum using Simlog's Forklift Personal Simulators. After passing the final exams, all 10 students were awarded a forklift operator license by Joshua Hogrefe. After graduation, one of the students went to work as a forklift operator and another planned to attend college to pursue a career in the construction industry.

"The simulators have been a great instructional tool," explains Hogrefe. "They enable me to put the kids on a forklift safely at an early age. Before, I couldn’t put them on a forklift until they were 18, and they still did not have any hands-on experience.”

“I want all the students that go through my program to have forklift operator licenses,” continues Hogrefe. “It only takes training on my part, and the simulators have allowed me to step away from that training and focus my efforts on other parts of the curriculum.”

For the upcoming school year, 120 students have enrolled in the program, and another set of 10 students are expected to graduate from the Advanced class.

Looking to the Future

The TDL program at Bryan High School is working with different organizations to secure funding for the program’s evolution. The idea is to build a warehouse adjacent to the school’s building, and the plan has already received approval from the school district. Joshua Hogrefe would like to add more Simlog Forklift Personal Simulators to the program. The goal continues to be keeping students engaged and interested in pursuing a career in Transportation, Distribution and Logistics. Additional simulators ensure that students gain the foundation skills that will give them access to the greatest number of employment opportunities.