Double Sided A-Frame Bench

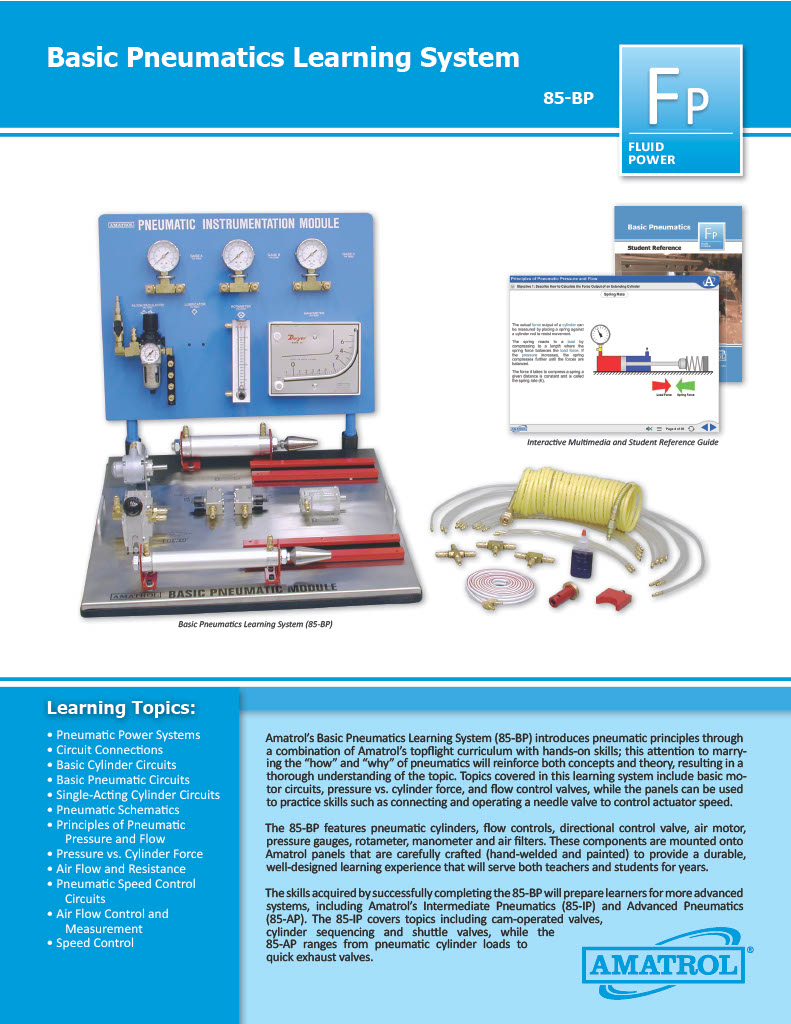

Amatrol’s Basic Pneumatics Training System – Double Sided A-Frame Bench (850-PD1) features the Basic Pneumatics Learning System (85-BP) panels mounted on a sturdy, durable A-frame bench with plenty of room for expansion.

Another set of Basic Pneumatics panels can be mounted to the opposite side of the bench to double training capacity, or more advanced pneumatic concepts can be taught by adding Intermediate Pneumatics (85-IP), Advanced Pneumatics (85-AP), or Electro-Pneumatics (85-EP) systems.

Amatrol’s Advanced Pneumatics training system (85-AP) covers a diverse range of topics, such as how air bearings, pneumatic motors, and pneumatic cylinders are used to move loads; applications for vacuums such as food packaging, as well as how to measure vacuum levels; and a comprehensive look at air compressors, their components, and how to safely operate them. By taking the approach of melding theory and practice, Amatrol curriculum reinforces both, resulting in a learner that can calculate the theoretical lifting force of a vacuum cup and understand how to select the correct pneumatic motor for a specific task.

The 85-AP includes an orifice plate flow meter, quick exhaust valve, suction cup, vacuum generator, vacuum gauge, tubing kit, and weight set with various sizes. These industrial-grade components ensure that learners work with instruments they’d normally only see on the job, which helps them to gain confidence and experience. This commitment to providing real-world components is an example of the attention to quality and detail that’s made Amatrol the world’s leader in skills-based, interactive technical learning.

Because hydraulic power is used in everything from automotive brakes to industrial robots, the skills taught by Amatrol’s Basic Hydraulics Learning System (85-BH) can open the doors to careers in various fields, such as manufacturing, transportation, agricultural, and construction. Basic Hydraulics training introduces the fundamental hydraulic principles, such as pressure and flow, while simultaneously teaching industry-relevant hydraulic skills; this signature Amatrol approach to curriculum reinforces both theory and practice, which produces a well-rounded understanding of the topic. As an example, after completing this training system, learners will not only be able to basic hydraulic operation, installation, design, and troubleshooting for various applications, but also understand concepts like flow rate versus cylinder speed and pressure versus cylinder force.

Basic Hydraulic training includes gauges, manifolds, cylinders, valves (relief/sequence, pressure reducing, check, directional control), flow meter, and hydraulic motor. These components are all industrial quality to ensure durability and help learners become better prepared for what they will encounter on the job. All Amatrol products are made from top-notch materials and carefully crafted (hand-welded, painted, and silk-screened) to create tough, attractive, well designed industrial training systems that facilitate learning and will serve teachers and students for years.

Amatrol’s Basic Pneumatics training system (85-BP) introduces pneumatic principles through a combination of Amatrol’s top-flight multimedia curriculum with hands-on industrial pneumatic skill-building. Topics covered in this learning system include single-acting cylinder circuits, pressure vs. cylinder force, and flow control valves, while the panels can be used to practice skills such as connecting and operating a needle valve to control actuator speed.

The pneumatics training system includes pneumatic cylinders, flow controls, directional control valves, an air motor, pressure gauges, rotameter, manometer, and air filters. These components are mounted onto Amatrol panels that are carefully crafted (hand-welded and painted) to provide a durable, well designed learning experience that will serve teachers and students for years. The skills acquired by completing the basic pneumatics training system will prepare learners for more advanced concepts and pneumatic applications, including Amatrol’s Intermediate Pneumatics (85-IP) and Advanced Pneumatics (85-AP) systems.

Amatrol’s Electro-Fluid Power Learning System (85-EF) can be used with eight different basic pneumatic or hydraulic learning systems to teach electrical relay control of hydraulic and pneumatic systems and their industry applications. Learners will practice industry-relevant skills related to these new topics including developing a sequence of operations given an application, connecting and operating an indicator lamp given a ladder diagram, and many more!

The Electro-Fluid Power training system provides learners with the components to set up a variety of industrial relay control circuits using ladder diagrams and Boolean logic. Some of these components include selector, pushbutton, limit, and pressure switches; control and timer relays; and hydraulic and pneumatic directional control valves.

The Electro-Hydraulics Training System (85-EH) teaches electrical relay control of industrial hydraulic applications. Learners will study industry-relevant electro-hydraulic skills including operation, installation, performance analysis, and design. The electro-hydraulic training system can be used with Basic Hydraulics (85-BH) or any Amatrol learning system that includes the Basic Hydraulics training system. Electro-Hydraulics can also optionally be used with Intermediate Hydraulics (85-IH).

The Electro-Hydraulics training system includes an electrical control panel with relay control components and an electrical valve module with solenoid-operated hydraulic directional control valves and electrical / electronic sensors. These components will be used to study a variety of topics including electrical control systems, basic control devices, power devices, control relays, sequencing control, timer control, pressure control applications, and circuit applications.

Amatrol’s Electro-Pneumatics Learning System (85-EP) adds to the Basic Pneumatics Learning System (850-P1) to teach electrical relay control of pneumatic systems and their industry applications. Learners will study industry-relevant skills related to these topics including operation, installation, performance analysis, and design.

The 85-EP provides students with the components to set up a variety of industrial relay control circuits using ladder diagrams and Boolean logic. Relay control is a fundamental building block in the study of automation since programmable controllers and solid state controls also use the same programming methods.

The model 85-EP includes an Electrical Control Module with relay control components, Electrical Valve Module with solenoid operated pneumatic directional control valves and electrical/electronic sensors, lead set, student curriculum for both theory and lab, student reference guide, and an instructor’s guide.

The Grid-Tie Learning System – Solar (85-GT1) features real-world components that are commonly found in commercial and residential environments to help make learners job-ready and prepares them for certifications. For example, the 85-GT1 is equipped with a Photovoltaic Combiner box and a multiple panel solar array, allowing learners to connect panels in series and parallel; an Iskra ME162 single-phase meter that measures and registers electric energy in single phase two-wire networks using globally-recognized products; and an Enphase Solar Microinverter that helps students understand converting DC generated by a single solar module to AC.

Amatrol’s Intermediate Hydraulics training system (85-IH) introduces advanced hydraulic components (pilot-operated check valves, two-position directional control valves, telescoping cylinders, etc.), explains how each works, and then shows how they relate to real-world applications in elevators, punch presses, backhoes, and many more. This approach to curriculum is an Amatrol signature: reinforce both theory and practice to produce a well-rounded understanding of the topic. Learners will be able to understand concepts like pressure intensification and cylinder regeneration while also being able to operate, install, design, and troubleshoot hydraulic components.

Intermediate Hydraulics includes directional control valves, relief valves, a flow control valve, a check valve, and an accumulator. Amatrol training systems use industrial-grade components displayed on hand-welded, painted and silk-screened panels, and workbenches made from top-flight materials. This precise attention to quality and detail ensures a tough, visually appealing, user-friendly design that will last for years and help learners gain experience with components they’ll actually see on the job.

The skills and principles offered in Intermediate Hydraulics build on the fundamentals taught by the Basic Hydraulics (85-BH), but also lead to additional, more advanced learning systems such as Advanced Hydraulics (85-AH) and Electro-Hydraulics (85-EH). The advanced hydraulics training system teaches learners about hydraulic performance analysis and maintenance, while the electro-hydraulics training system (which is used in several exercises with the intermediate hydraulics training system) introduces electrical relay control of hydraulic systems.

Amatrol’s Intermediate Pneumatics Training System (85-IP) builds on basic pneumatic skills by introducing more advanced concepts such as air logic, ways to decelerate a pneumatic cylinder, and how to prevent condensation in a pneumatic circuit. Learners will have the opportunity to study these concepts while working with a hands-on training module, which enables practicing skills such as connecting and operating a two-way valve and changing an air filter element; this approach of simultaneously teaching theory and practice reinforces each element and results in a thorough understanding of the topic.

The Intermediate Pneumatics training system includes directional control valves, check valve, pneumatic cylinder, Venturi block, assorted filter elements, and much more. Amatrol’s commitment to using top-flight, industry-standard materials ensures that learners work with components they’ll actually see on the job. This attention to quality and detail culminates in a durable, attractive, user-friendly industrial training system that will last for years.

After completing the Intermediate Pneumatics curriculum, learners can continue to build on these skills by moving on to Amatrol’s Advances Pneumatics (85-AP) and the Pneumatics Troubleshooting (950-PT1) training systems. Advanced Pneumatics covers topics such as motor loads, pneumatic cylinder loads, and quick exhaust valves, while Pneumatic Troubleshooting is the first product to offer a realistic troubleshooting experience for learners because the faults are inserted throughout the system.

Pages

-

Enhance port training with CM Labs’ Double Empty Container Handler Add-On—an exclusive simulation module for twin-lift operations, including safe container stacking, ITV trailer interaction, and obstacle navigation.

-

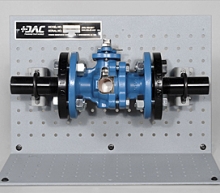

Item Number:253DDAC Worldwide's Downsized Ball Valve Cutaway (253D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in industrial ball valves' design, construction, and maintenance. Through carefully-planned sectioning and color-coding, the complete internal configuration of the valve is exposed and showcased. This tabletop sample supports training in a variety of process-related industries.

-

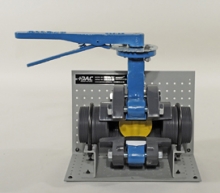

Item Number:254DDAC Worldwide's Downsized Butterfly Valve Cutaway (254D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in the design, construction, and maintenance of industrial concentric, wafer-type resilient seat butterfly valves. Through carefully-planned sectioning and color-coding, the complete internal configuration of the valve is exposed and showcased.

-

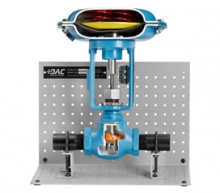

Item Number:255DDAC Worldwide's Downsized Control Valve Cutaway (255D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in the operation, construction, and maintenance of a pneumatically-operated, control valve. Through carefully planned sectioning and color-coding, the complete internal configuration of the valve is exposed and showcased. Seal features, actuator components, and hardware locations have been retained, allowing for “hands-on” training in maintenance.

-

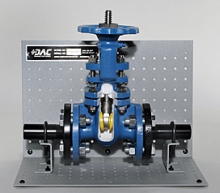

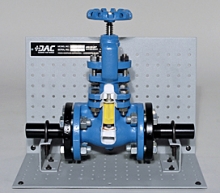

Item Number:251DDAC Worldwide's Downsized Gate Valve Cutaway (251D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in the design, construction, and maintenance of industrial gate valves. This tabletop sample supports training in a variety of process-related industries.

-

Item Number:252DDAC Worldwide's Downsized Globe Valve Cutaway (252D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in the design, construction, and maintenance of industrial globe valves.

-

Item Number:275-160DDAC Worldwide’s Downsized Horizontal Multi-Stage Centrifugal Pump Dissectible (275-160D) is an industrial pump assembly that allows for in-depth training in the field or bench-top disassembly, inspection, troubleshooting, and assembly of multi-staged pumps.

-

Item Number:205-220DDAC Worldwide’s Downsized Right-Angle Spiral Bevel Gear Reducer Cutaway (205-220D) highlights a sectioned, small-scale industrial gear reducer for classroom and laboratory training related to mechanical drives.

-

Item Number:DRJThe simulation software puts you at the controls of a modern twin boom Drill Jumbo in an underground mining tunnel (drift). You can even change the viewpoint during the simulation at the touch of a button!

-

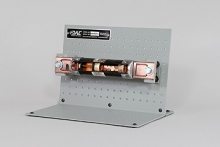

Item Number:273-960DAC Worldwide’s Dual Element, Time-Delay Fuse Cutaway (273-960) is a detailed and professionally-crafted electrical fuse cutaway that depicts a common dual-element, time-delay industrial fuse.