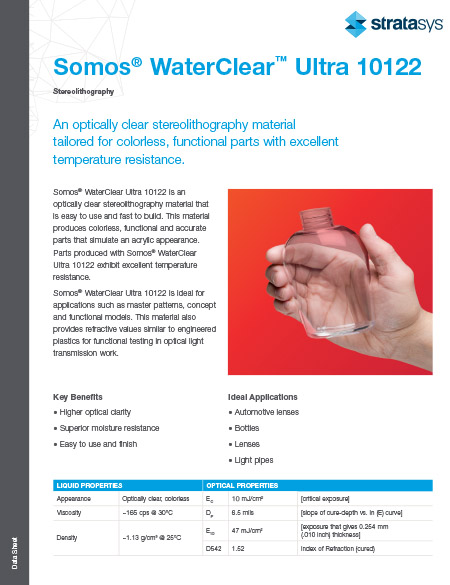

An optically clear stereolithography material tailored for colorless, functional parts with excellent temperature resistance.

Somos® WaterClear Ultra 10122 is an optically clear stereolithography material that is easy to use and fast to build. This material produces colorless, functional, and accurate parts that simulate an acrylic appearance. Parts produced with Somos® WaterClear Ultra 10122 exhibit excellent temperature resistance.

Somos® WaterClear Ultra 10122 is ideal for applications such as master patterns, concept, and functional models. This material also provides refractive values similar to engineered plastics for functional testing in optical light transmission work.

Somos® WaterClear® Ultra 10122 is an optically clear stereolithography material that is easy to use and fast to build. This stereolithography material produces colorless, functional, and accurate parts that simulate an acrylic appearance. Parts produced with Somos WaterClear Ultra 10122 exhibit excellent water and temperature resistance.

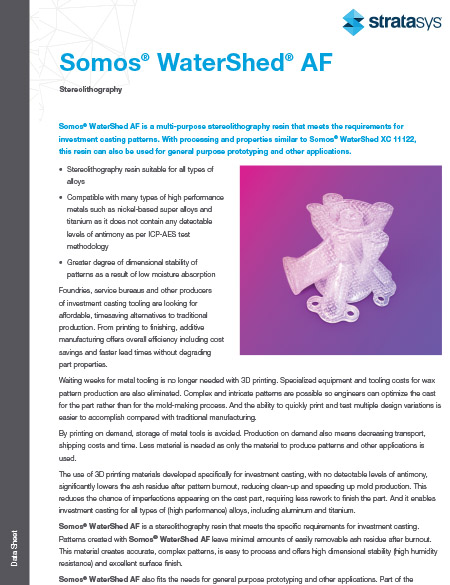

Somos® WaterShed AF is a multi-purpose stereolithography resin that meets the requirements for investment casting patterns. With processing and properties similar to Somos® WaterShed XC 11122, this resin can also be used for general-purpose prototyping and other applications.

Somos® WaterShed® AF is a multi-purpose stereolithography resin that meets the requirements for investment casting patterns, as it is antimony-free. Patterns created with Somos WaterShed AF leave much lower ash residue after burnout, reducing clean-up and speeding up mold production.

Multipurpose resin that prints 50% faster than alternatives eliminating the need for painting.

Somos®® WaterShed XC 11122, has up to a 50% faster processing speed, offering minimal finishing and more consistent processing over time. Compared to alternatives currently on the market, Somos® WaterShed Black prints a more true black color off the machine. The material offers a smooth surface finish and higher moisture and chemical resistance.

Somos® WaterShed® XC 11122 is the clear solution for designers looking for ABS and PBT-like properties for stereolithography technology. One of our most popular resins, Somos WaterShed XC 11122 produces highly detailed parts with superior clarity and water-resistance.

As one of the industry’s most popular materials, Somos® WaterShed® XC 11122 is the clear solution for numerous applications. Whether you’re a designer looking for highly detailed parts with superior clarity and water resistance or an engineer focusing on durability for functional testing, Somos® WaterShed XC 11122 mimics the look and feel of clear thermoplastics, such as ABS and PBT.

Somos® WaterShed® XC 11122 produces optically clear parts with a smooth finish, and it’s ease of use helps to shorten product development and testing. This versatility means Somos® WaterShed® XC 11122 is the ideal material in markets such as automotive, aerospace, and consumer electronics for applications including packaging, RTV patterns, durable concept models, wind tunnel testing, and investment casting patterns.

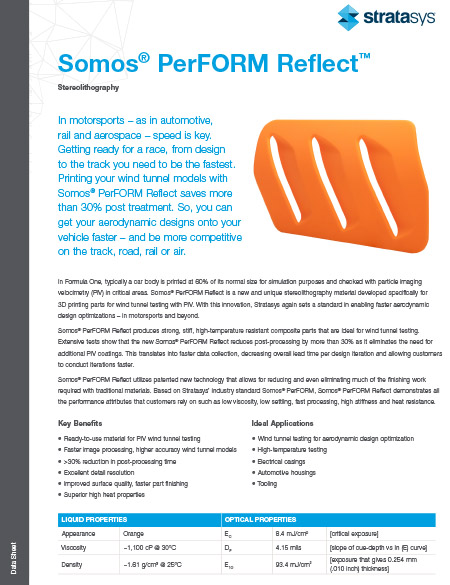

In motorsports – as in automotive, rail, and aerospace – speed is key. Getting ready for a race, from design to the track, you need to be the fastest. Printing your wind tunnel models with Somos® PerFORM Reflect saves more than 30% post-treatment. So, you can get your aerodynamic designs onto your vehicle faster – and be more competitive on the track, road, rail, or air.

In Formula One, a car body is typically printed at 60% of its normal size for simulation purposes and checked with particle imaging velocimetry (PIV) in critical areas. Somos® PerFORM Reflect is a new and unique stereolithography material developed specifically for 3D printing parts for wind tunnel testing with PIV. With this innovation, Stratasys again sets a standard in enabling faster aerodynamic design optimizations – in motorsports and beyond.

Somos® PerFORM Reflect produces strong, stiff, high-temperature resistant composite parts that are ideal for wind tunnel testing. Extensive tests show that the new Somos® PerFORM Reflect reduces post-processing by more than 30%, eliminating the need for additional PIV coatings. This translates into faster data collection, decreasing overall lead time per design iteration and allowing customers to conduct iterations faster.

Somos® PerFORM Reflect utilizes patented new technology that reduces and even eliminates much of the finishing work required with traditional materials. Based on Stratasys’ industry-standard Somos® PerFORM, Somos® PerFORM Reflect demonstrates all the performance attributes that customers rely on, such as low viscosity, low settling, fast processing, high stiffness, and heat resistance.

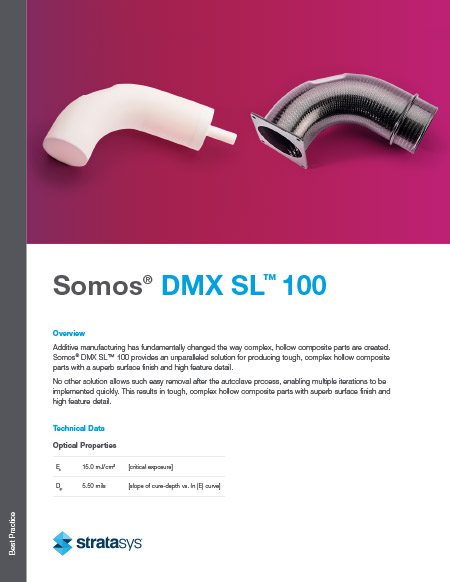

Additive manufacturing has fundamentally changed how complex, hollow composite parts are created. Somos® DMX SL™ 100 provides an unparalleled solution for producing tough, complex hollow composite parts with a superb surface finish and high feature detail.

No other solution allows such easy removal after the autoclave process, enabling multiple iterations to be implemented quickly. This results in tough, complex hollow composite parts with superb surface finish and high feature detail.

Pages

-

Item Number:F900The F900 gives you the ability to create large parts or multiple smaller parts in the broadest array of FDM materials. With the largest build chamber available among FDM printers, the F900 enables additive manufacturing at scale while delivering consistent, accurate results.

-

Item Number:450mc and 380mcThe Fortus 450mc can run standard, engineering, and high-performance FDM thermoplastics in a 16 x 14 x 16 in. build envelope. It features improved ease of use, including a touchscreen user interface, and builds complex parts faster than its predecessor, the 400mc.

-

Meet high production demands with the Stratasys H350 powder bed fusion 3D printer. Leveraging Selective Absorption Fusion, SAF technology, into the H-Series production platform, the Stratasys H350 is designed to deliver functional, production-grade parts with unrivaled consistency.

-

Item Number:J4100Whatever the complexity, the J4100 can handle any design. An ultra-large build tray, multi-material capabilities, fast throughput, and a wide range of material properties mean unlimited design possibilities and improved productivity.

-

Item Number:J850 Pro / J850 Prime / J826 PrimeFrom ideation to creation, the J8 Series delivers a fully-functioning, multi-material, Pantone™ validated prototype 200% faster than traditional methods.

-

The J850™ TechStyle™ 3D printer is powered by 3DFashion™ technology and provides full-color, multi-material capabilities for designs that can be printed directly to fabric, garments, footwear, and luxury accessories, delivering results that are not possible with traditional methods.

-

Item Number:Neo450e / Neo450sThe Stratasys Neo450e is an affordable industrial-grade 3D printer producing small to medium parts with consistent accuracy and repeatability. The Neo450s offers performance and versatility along with all the benefits of Neo450e.

-

Item Number:NEO800The open-system Stratasys Neo800 3D Printer uses Stereolithography (SL) technology to delivers high-quality parts with superior surface quality, accuracy, and detail at unprecedented speeds.

-

Objet30 Prime offers four additional materials expanding to rubber-like materials for soft-touch features, flexible components, and even bio-compatible for medical device prototyping and end-use parts such as surgical guides.