National Certifications for Robotics and Advanced Automation Manufacturing

With FANUC's challenging and thorough national certification assessments, students and workers can document their knowledge and fill high-demand, high-paying, and exciting career opportunities in Robotics and Advanced Manufacturing. An extensive network of high schools, colleges, and training centers offers these national certifications.

Supported Certifications

FANUC Robot Operator 1

Indicates an operator level of skills and knowledge. Students with this level have a basic understanding of robot operations and programming, material handling and its components, and an introduction to Roboguide simulation software. These certification programs are focused on the core Robot Operator skills needed by entry-level or incumbent workers.

Written assessment for entry-level position as robotics associate in manufacturing. The assessment exams allow the candidate to demonstrate their knowledge in: Robot operations, frame setup, writing, modifying and executing basic programs, program offset, backup, restorations, creating and modifying simulations.

Training Solutions

Supported Certifications

EPA Section 608 Certification

For working on stationary HVACR equipment

Section 608 of the Federal Clean Air Act requires that all individuals who maintain, service, repair, or dispose of appliances that contain ozone-depleting refrigerants be certified in proper refrigerant handling techniques.

Training Solutions

What is PolyJet Technology?

PolyJet is a powerful 3D printing technology that produces smooth, accurate parts, prototypes and tooling. With microscopic layer resolution and accuracy down to 0.014 mm, it can produce thin walls and complex geometries using the widest range of materials available with any technology.

Benefits of PolyJet:

- Create smooth, detailed prototypes that convey final-product aesthetics.

- Produce accurate molds, jigs, fixtures and other manufacturing tools.

- Achieve complex shapes, intricate details and delicate features.

- Incorporate the widest variety of colors and materials into a single model for unbeatable efficiency.

Make it more realistic and accurate with PolyJet

Stratasys offers PolyJet technology 3D prints in the widest variety of materials, so you can create ergonomic tooling, bio-compatible surgical guides or realistic prototypes that closely resemble finished products.

Models are precisely printed in layers as fine as 16 microns for smooth surfaces and complex geometries. Material properties range from rubber-like to rigid, transparent to opaque, neutral to vibrantly colored, and standard to bio-compatible plastics.

Stratasys FDM (Fused Deposition Modeling) materials are engineered to deliver unmatched performance, durability, and precision for additive manufacturing applications across industries. From prototyping to production, Stratasys offers a wide range of thermoplastics—each designed to meet specific mechanical, thermal, and chemical requirements. Whether you're creating functional prototypes, end-use parts, or manufacturing tools, Stratasys FDM materials provide the reliability and repeatability that engineers, educators, and manufacturers demand.

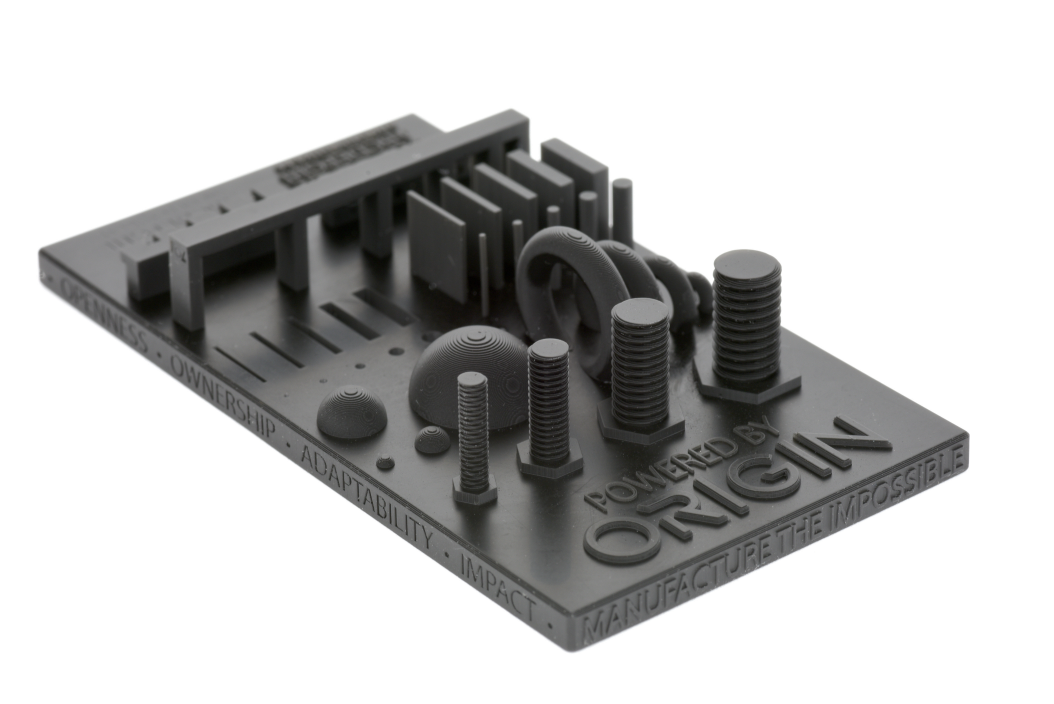

Get ready for a new era of 3D printing.

Programmable PhotoPolymerization P3™ technology, an evolution of digital light processing (DLP) is ushering in a new era in 3D printing: the mass production of functional end-use parts.

P3 software precisely orchestrates light, temperature, pull forces and pneumatics to optimize prints for the best possible results. With P3, manufacturers can achieve injection molding part quality and surface finish with incredible accuracy, in a diverse and continuously growing range of high-performance materials.

What makes P3 unique?

P3 is a combination of several tightly controlled, programmable steps in the printing process. P3 extends DLP printing’s capabilities and supports the next generation of production applications made with photopolymers. This powerful combination of production-grade technology and performance materials unlocks functional end-use applications in 3D printing with competitive throughput and part cost.

How it works:

Four critical parts of the P3 process enable the unique combination of high throughput, production-grade part quality and materials.

- Light: Programmable light sets off an exothermic reaction that forms layers with outstanding resolution, accuracy and dosage control.

- Environmental stability: Temperature-controlled printing mitigates warping and shrinkage, while unlocking materials with advanced properties, like flame retardancy.

- Pneumatic separation: A perfectly timed separation procedure reduces pull forces, leading to a molded-like surface finish, high-throughput and ultra-fine features, such as textures or large surface areas like molds.

- Motion: Precise control over printer movements ensures a repeatable, fast and accurate workflow in a wide range of geometries and high-performance materials.

- Green Strength: The P3 process produces a high polymerization conversion, unlocking faster print times, extreme geometries, and build nesting.

Stereolithography is an additive manufacturing process that uses a vat of liquid UV-curable photopolymer resin and a UV laser to build parts one layer at a time.

Benefits of stereolithography include:

- Parts with smooth sidewall quality and detail

- Low-volume part production of complex geometries

- Tight tolerances, layer thickness of between 50 to 200 microns

- Versatile range of materials for specific applications

Stereolithography is commonly used as a prototyping technology within industries that need to print parts or models to validate fit form and function or for concept visualization. Stereolithography is also used in manufacturing applications for short-run part production, such as vacuum castings, injection mold tooling, investment casting master patterns, and functional end-use part production for certain environments.

Due to its competitive build times and the superior quality of the finish straight off the machine, very little post-processing is required, providing cost savings and reduced lead times.

SAF™ Selective Absorption Fusion™

Boost your manufacturing capability with powder bed fusion 3D printing.

SAF technology is the power behind the H Series™ Production Platform, designed for production-level throughput of end-use parts.

The SAF-powered H350™ 3D printer provides you with control over your production and costs. Grow your business through volume production with consistent end-use functional parts.

What is SAF?

SAF is the industrial-grade technology that powers the powder-based additive manufacturing process, leading to higher end-use parts production levels. SAF is the latest 3D printing technology behind the H Series Production Platform that enables control over the printing process to achieve accurate, consistent production at competitive part costs.

How SAF technology works:

SAF is the technology behind the H350’s powder bed fusion 3D printing process. SAF uses HAF™ infrared absorption fluid to fuse polymer powder particles in layers to build parts. It also utilizes Big Wave™ powder management, a proprietary technology that provides reliable powder distribution across the build, where industrial-grade piezo-electric print heads jet the HAF fluid in prescribed areas to create each part cross-section. This is followed by exposure to infrared energy, which causes the areas with HAF to melt and fuse. The sequence is repeated until the parts are completed.

Typical Applications

Industrial-grade technology

Industrial Piezo-electric print heads and innovative powder management designed for durability and high uptime.

Production throughput

One-pass print-and fuse, few consumable replacements for minimal downtime, and high nesting densities to meet production demands.

End-use production parts

Real-time powder heating, unique thermal management, and broad powder range for a wide spectrum of part properties.

Advancing Additive Manufacturing

FDM 3D printed parts are tough enough to be used as advanced conceptual models, functional prototypes, manufacturing tools, and production parts. Using strong, reliable, and durable materials, FDM 3D printers streamline production processes from design through manufacturing, reducing costs and eliminating traditional barriers.

Download our FDM 3D printer systems and materials overview brochure. A much-needed asset for your entry into FDM 3D printing.

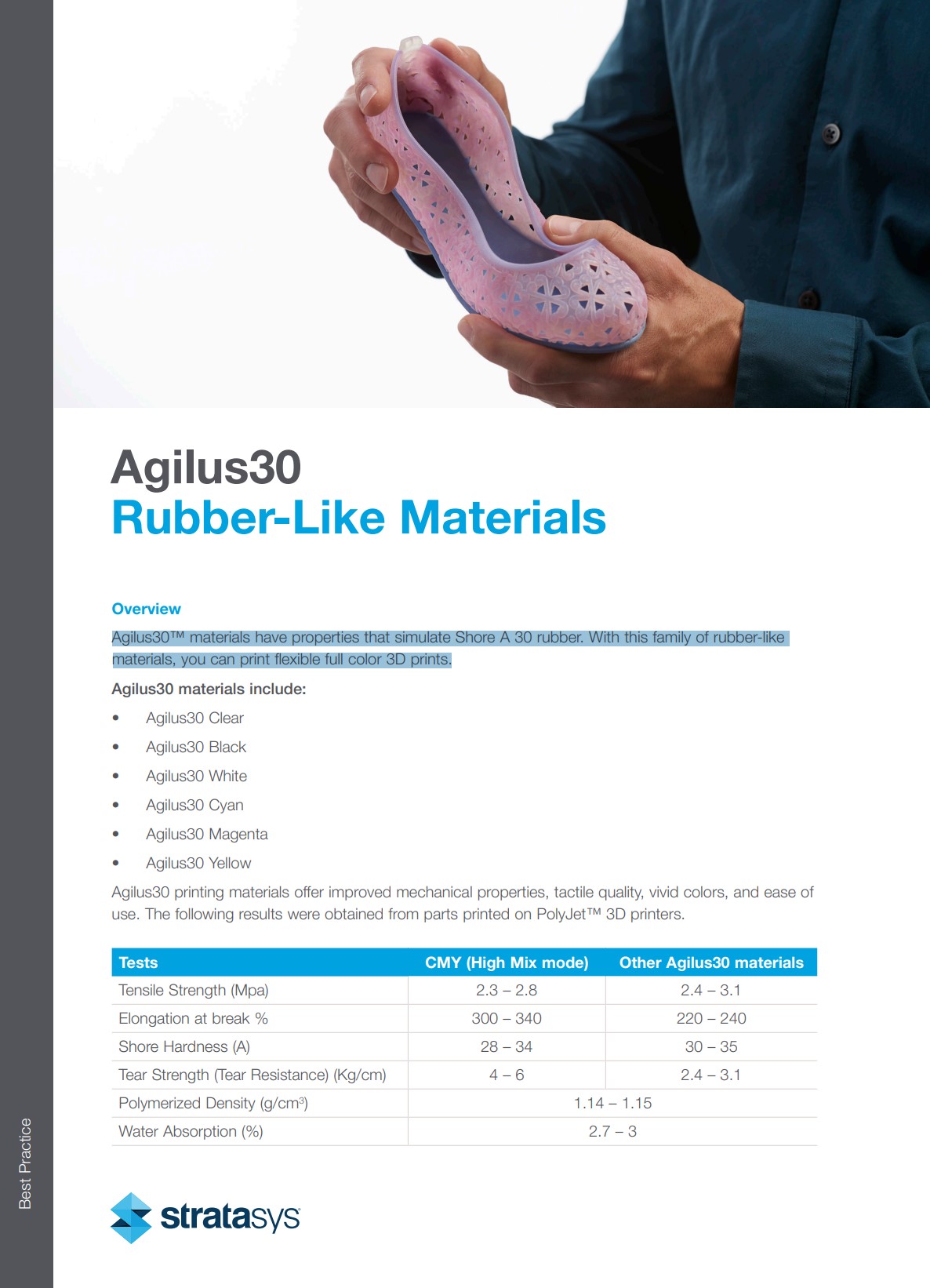

Agilus30™ materials have properties that simulate Shore A 30 rubber. With this family of rubber-like materials, you can print flexible full-color 3D prints.

Pages

-

Item Number:603-SPDiscover the DAC Worldwide Smart Process Plant Training System (603-SP). Equip learners with hands-on training in process control systems, including level, pressure, temperature, flow, and pH, using industry-standard components and advanced software.

-

Item Number:87-SWPF1VThe 87-SWPF1V Smart Robot Logistics Palletizing Workcell, which includes a mobile workstation with a FANUC 6-axis robotic arm, teaches students how to operate, program, maintain, and troubleshoot a robotic palletizing workcell.

-

Item Number:99-PG2The 99-PG2 includes a digital snap gauge and a master part turned to precisely 0.500”, which learners use to calibrate the device. As the learners work their way through the curriculum, they use the snap gauge to measure custom parts from the 990-PG1 that ensure a complete learning experience.

-

Item Number:SG-a-H, SG-a-S, SG-b-HThe OnRobot Soft Gripper is able to pick a wide array of irregular shapes and delicate items, making it ideal for pick-and-place applications in food and beverage production, as well as manufacturing or packaging.

-

Item Number:950-SC1Amatrol’s Solar Concepts Learning System (950-SC1) introduces learners to a broad range of basic concepts in solar energy and technology.

-

Item Number:950-SPF1Train future solar technicians with Amatrol’s Solar PV Installation Learning System (950-SPF1), a hands-on trainer that prepares learners for NABCEP certification and solar industry careers.

-

Item Number:950-SPT1Master solar energy troubleshooting with Amatrol’s 950-SPT1. This hands-on training system teaches PV system operation, maintenance, and diagnostics using real industrial components and multimedia eLearning.

-

Item Number:950-STF1Prepare for NABCEP certification with Amatrol’s Solar Thermal Installation Training System (950-STF1). Learn hands-on solar thermal system installation and commissioning for commercial and residential applications.

-

Item Number:200-2045DAC Worldwide’s Spherical Roller Bearing Pillow Block Assembly Cutaway (200-2045) is a carefully-sectioned, industrial-quality spherical roller bearing pillow block assembly designed to be used in either classroom or laboratory mechanical drives training. Each unit is an actual piece of industrial equipment chosen from common models by well-known U.S. manufacturers for training relevance.

-

Item Number:410-000

AC electric motors are found in a wide variety of industrial, commercial, and residential applications. Industrial maintenance technicians must develop industry-relevant skills, such as how to operate, install, design, and troubleshoot AC electric motor control circuits for various applications.