Date: Thursday, October 23, 2025

Location: Grapevine Convention Center

Amatrol Skill Boss Manufacturing

Amatrol’s Skill Boss Manufacturing is a portable, hands-on training and assessment system designed to meet the rigorous standards of the Manufacturing Skill Standards Council (MSSC). Built for the Certified Production Technician (CPT+) program, this system evaluates over 60 essential skills across safety, quality practices, production processes, and maintenance awareness.

The Skill Boss system replicates real-world manufacturing tasks, including assembly, machine operation, and troubleshooting. Learners gain practical experience with components such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), electro-pneumatic systems, sensors, mechanical drives, and robotic pick-and-place systems. By completing CPT+, individuals prove both their technical knowledge and applied competency, making them job-ready for advanced manufacturing careers.

- Assess and train in Safety, Quality, Production, and Maintenance

- Hands-on demonstrations in electrical, fluid power, mechanical, and electronic systems

- Supports MSSC’s Certified Production Technician Plus (CPT+) certification

- Portable design for classrooms, training centers, and workforce development programs

With its real-world finishing and sorting process, Skill Boss Manufacturing automatically feeds, sorts, and polishes parts, while learners control and monitor operations. The system’s design provides educators and employers with a reliable way to both develop and validate critical advanced manufacturing skills.

Levil Technology EDU-RoboMill: CNC Precision Meets FANUC Robotics

The EDU-RoboMill brings together the world of CNC machining and FANUC robotics in a single, compact solution designed for both education and industrial applications. Built with precision and durability in mind, the RoboMill allows students to practice robot programming, CNC fundamentals, and integrated automation—all in a footprint that fits through a standard 35″ doorway. Its combination of industrial-grade controls and accessible design makes it the perfect choice for classrooms, labs, and training centers preparing the next generation of advanced manufacturing professionals.

- Robot G-code Control: FANUC CNC issues coordinated X/Y/Z moves to the robot, enabling true CNC-style motion paths.

- Compact & Classroom-Ready: Fits standard doorways and runs on single-phase power for easy integration into labs.

- High Precision: Achieves repeatability down to ~0.0012 in (0.03 mm).

- Spindle Options: Configurable spindles with automatic tool changer (ATC), high-speed air-cooled motors, and rigid tapping capability.

- Industrial Flexibility: Train in robotics, CNC machining, and real-world automation tasks on one versatile platform.

Technical Highlights

- Precision & Feeds: ~0.0012 in (0.03 mm) precision; 79 ipm rapid feed; 59 ipm cutting feed.

- Power: 220 VAC, single-phase, 15 A (step-up/down transformer available for 110 VAC).

- Drive System: In-line direct drive with linear guideways and ball screws for smooth motion.

- Spindle Speeds: Options up to 30,000 rpm depending on configuration.

- Dimensions: 83.6″ W x 74.7″ H x 32.9″ D; fits through 35″ doorway.

FANUC Robot Compatibility

- LR-Mate 200iD/4S

- LR-Mate 200iD

- LR-Mate 200iD/7L

- LR-Mate 200iSD/14L

- LR-10iA/10

Other FANUC robots may be used; larger models may affect doorway clearance and table dimensions.

Pages

-

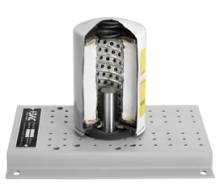

Item Number:275-130DAC Worldwide’s Hydraulic Diaphragm Pump Dissectible (275-130) features a fully restored industrial positive displacement diaphragm pump to create a teaching aid for process pump maintenance training.

-

Item Number:HEXSimlog's Hydraulic Excavator Personal Simulator puts trainees at the controls of a modern Hydraulic Excavator in interaction with an articulated dump truck. Using life-like dynamic terrain combined with our intelligent instructional design, your trainees are guided through a series of 12 skill-building Simulation Modules.

-

Item Number:773-055DAC Worldwide’s Hydraulic Filter Cutaway (773-055) is a professionally-crafted sectioned example of a commonly-encountered sump-type hydraulic filter used in hydraulic systems to maintain oil quality and machine health. The training aid enhances classroom training in hydraulic system design, maintenance, troubleshooting, and preventive/predictive maintenance.

-

Item Number:773-050DAC Worldwide's Hydraulic Pressure Gauge Cutaway (773-050) is a Bourdon tube-type pressure widely used in industrial liquid and gas processes to monitor and document system pressures. The full-size, fully-detailed example gives learners a first-hand view into a component that is found in various applications worldwide.

-

Item Number:773-217DAC Worldwide's Hydraulic Pressure Relief Valve Cutaway, Balanced Piston-Type (773-217) is a sectioned hydraulic, automatically triggered relief valve example with a two-stage balanced piston design, which incorporates a commonly-encountered valve type manufactured by an industry leader. T

-

Item Number:773-213DAC Worldwide's Hydraulic Sequence Valve Cutaway (773-213) is a sectioned hydraulic sequence valve example with a two-stage balanced piston design, which incorporates a commonly-encountered valve type manufactured by an industry leader.

-

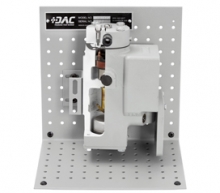

Item Number:273-840DAC Worldwide’s I/P Transducer Cutaway (273-840) is a detailed I/P converter cutaway that depicts a common current-to-pressure transducer used within industrial process control systems. This common piece of pneumatic control hardware is found in manufacturing facilities, petrochemical plants, refineries, and other similar industrial, commercial, and oil and gas applications.

-

Amatrol's IGNITE: Mastering Manufacturing program teaches Industrial Internet of things (IIoT) & Industry 4.0 skills required for today's manufacturing careers.

-

Item Number:ILS12.150DThe ILS12.150D is a free-standing platform with a materials processing envelope of 48" x 24" x 12" or 13,824 in³. The dual laser platform supports a power range of 10 to 150 watts (up to 75 watts with one 10.6µm CO2 laser; up to 150 watts with a second 10.6µm CO2 laser). The ILS12.150D also supports a single 9.3µm laser at 30, 50 or 75 watts (If a 9.3µm CO2 laser is installed, the maximum 10.6µm laser is 75 watts).

-

Item Number:ILS12.75The ILS12.75 is a free-standing platform with a materials processing envelope of 48" x 24" x 12" or 13,824 in³. The single laser platform supports either one 10.6µm CO2 laser (10 to 75 watts) or one 9.3µm CO2 laser (30, 50 or 75 watts).