Briggs Automotive Company (BAC), the renowned British supercar manufacturer behind the Mono and Mono R, has integrated UltiMaker S Series 3D printers into their production and prototyping workflow. With over 44 custom components 3D printed on-site, BAC has transformed its design process, cutting costs and increasing the speed of production using industrial-grade materials like carbon fiber–reinforced nylon.

By leveraging the full UltiMaker ecosystem—including Digital Factory, open-material compatibility, and integrated slicing—BAC’s engineering team can prototype and manufacture lightweight, structurally sound components such as air inlet runners, mirror arms, and light surrounds. With UltiMaker’s precision and flexibility, BAC gains critical design freedom while maintaining the strength and performance required of parts used at speeds exceeding 270 km/h.

Highlights from BAC’s Use of UltiMaker S Series

- 44+ custom 3D printed parts: Including structural engine components, mirror mounts, and light surrounds

- Cost reductions: Mirror arms costing £400 when machined now printed for just £90

- Production-ready prototypes: Parts printed in Covestro’s carbon fiber–reinforced nylon (Novamid CF10)

- Digital Factory integration: Remote monitoring, slicing, maintenance tracking, and version control

- Local support: Helped BAC adopt and scale 3D printing across R&D and production workflows

"The UltiMaker ecosystem allows us to bring every element of our production together. From material selection to printer management, it gives us total control and confidence in the quality of our parts." – Ian Briggs, Design Director and Co-founder, BAC

From rapid prototyping to functional end-use parts, the UltiMaker S Series gives BAC the power to move fast, customize freely, and produce precisely—all while maintaining the high-performance standards expected of a world-class supercar brand.

Think 3D printing is just for prototypes? Think again. With carbon fiber–reinforced materials, UltiMaker printers are producing strong, lightweight, and functional parts used directly in manufacturing, defense, and automotive industries. These aren’t just test models—they’re working components that are driving innovation on the ground, in the lab, and on the road.

From replacing aluminum end-of-arm tools to building structural parts for high-performance vehicles, UltiMaker users are tapping into the power of composites to cut costs, reduce weight, and manufacture faster than ever before. Carbon fiber printing unlocks real-world performance—without the need for metal.

What You’ll See

- Automotive teams 3D printing 44+ carbon fiber parts for production use

- End-of-arm tooling produced in under an hour

- Carbon-reinforced nylon filaments replacing machined aluminum

- Real-world stories from manufacturing and defense innovators

“What excites me about 3D printing is that the possibilities are pretty limitless.” – UltiMaker User

With UltiMaker composite materials, the line between prototyping and production is disappearing. Stronger, lighter, smarter. That’s the power of carbon fiber 3D printing.

The UltiMaker Method XL redefines what's possible in additive manufacturing by bridging the gap between desktop convenience and industrial-grade performance. Designed to meet the needs of engineers, product developers, and manufacturers, Method XL delivers precision, repeatability, and scale—without the traditional cost or complexity of industrial machines.

With its expansive build volume and actively heated build chamber, Method XL is meticulously engineered to produce large, durable, and complex parts with outstanding dimensional accuracy. It supports high-performance materials like ABS-R, ABS-CF, Nylon, and RapidRinse™ to meet the demands of functional prototyping and end-use manufacturing.

Engineered for Industrial Results

- Large build volume: Print full-size functional prototypes or multiple parts in one job

- Precision accuracy: Match the tolerances and finish of injection-molded parts

- Heated build chamber: Maintain consistent temperatures for warp-free prints

- Material versatility: Compatible with engineering composites and water-soluble supports

- Office-ready design: Advanced performance with a compact footprint

Whether you're producing precision tooling, fixtures, housings, or full-scale prototypes, the Method XL enables professional results with less time, less hassle, and greater freedom to innovate.

The MakerBot Sketch Series is built from the ground up for education, providing schools with the most reliable and accessible 3D printing setup available. Designed with ideal classroom-to-printer ratios, the Sketch Series helps educators maximize student engagement while reducing downtime and setup challenges.

Whether your students are new to 3D printing or ready to take on advanced design projects, the Sketch Series offers a turnkey solution with robust teacher training, student certification, and built-in safety features. Empower your classroom with hands-on learning, cross-curricular applications, and reliable results—every time.

Why Choose the Sketch 3D Printer Series?

- Classroom-optimized design: Compact, enclosed printers designed for safe and accessible use by students of all skill levels

- Ready-to-teach resources: Access to MakerBot certification programs, lesson plans, and project ideas

- Multi-printer management: Queue and monitor jobs across devices using MakerBot Cloud or Digital Factory

- Reliable performance: Built to reduce failed prints and increase student confidence

- Trusted by educators: Used in thousands of schools for STEM, CTE, and design programs

From elementary makerspaces to high school engineering labs, the Sketch Series gives educators the tools they need to bring creativity and innovation into the classroom—no prior experience required.

UltiMaker S7 Material Partner Testimonials

What happens when you hand the UltiMaker S7 to eight of the industry's leading material partners and let them test it using their own materials and STL files? You get real-world feedback on performance, precision, and print success—straight from the source.

Each partner brought their unique filament, ran their own tests, and explored how the S7’s new hardware features—including the PEI-coated flexible build plate, integrated Air Manager, and advanced active leveling—stand up to their most demanding print jobs.

What They Noticed

- Superior bed adhesion: Materials held firm to the new PEI-coated build plate—even without adhesives

- Easy part removal: Flexible build plate made removing strong-sticking parts quick and damage-free

- Improved thermal control: Single front door enhances temperature stability for large-format parts

- Real-time visibility: Integrated HD camera lets users monitor the entire print—not just the first layer

- Ecosystem confidence: Partners praised the reliability and openness of UltiMaker’s material and printer integration

“UltiMaker has always made machines that just work. With the S7, the full ecosystem—printer, materials, and software—comes together to deliver excellent results on the first try.”

From precision part production to material behavior testing, the S7 exceeded expectations across the board—proving once again why UltiMaker is trusted by professionals and material scientists worldwide.

The UltiMaker S Series is more than just a 3D printer—it's a complete professional ecosystem. From streamlined post-processing to advanced material capabilities, every accessory and integration is designed to maximize uptime, reduce manual effort, and expand the range of applications possible with the S3, S5, S7, and beyond.

Below are just a few standout highlights that showcase how the S Series grows with your needs and scales with your creativity.

- Efficient post-processing: Cut support dissolution time by up to 75%

- Hands-free removal: Consistent flow agitation removes PVA faster and more evenly

- Cleaner workspace: Enclosed design minimizes mess and requires minimal maintenance

- Print real metal parts: Compatible with BASF Forward AM Ultrafuse® 17-4 PH and 316L filaments

- Designed for S5 and S7: Fully validated workflows with slicing integration in Cura

- Complete workflow: Includes debinding/sintering partners and design guidelines

- Fleet management: Queue, monitor, and manage multiple printers remotely

- Print job tracking: View material usage, print success rates, and real-time status

- Scalable integration: Designed for multi-user teams and enterprise workflows

- UltiMaker Cura: Industry-leading slicing software with pre-configured material profiles

- Plugin support: Seamless integrations with SolidWorks, Siemens NX, Autodesk Inventor

- Enterprise access: UltiMaker Essentials for compliance, control, and collaboration

Whether you're optimizing support removal, printing in metal, or scaling across teams, the UltiMaker S Series ecosystem gives you the tools to Design. Print. Repeat.—faster, smarter, and more efficiently than ever.

The METHOD Pro Series has empowered designers and engineers across a wide range of industries to bring bold ideas to life. From toymakers and industrial designers to manufacturers and aerospace innovators, our customers have used METHOD and METHOD X to push the boundaries of what's possible with desktop 3D printing.

Whether printing functional prototypes, concept models, or production-ready tools, METHOD customers consistently highlight speed, accuracy, and seamless integration as the keys to success. Here are just a few real-world stories of how the METHOD Pro Series is making an impact.

Customer Highlights

- Mattel: Uses METHOD printers to accelerate toy development and bring ideas for the next generation of play to life

- Industrial Automation: Created an end-of-arm tool with METHOD X in under 48 minutes—ready for use straight off the build plate

- Return on Investment: One customer reported full ROI on their METHOD X printer within 3–4 months

- NASA Collaboration: METHOD X helped support rapid iteration for parts used in instrumentation on the James Webb Space Telescope

- Design Freedom: High dimensional accuracy and easy-to-use features allow users to prototype without limits

“With METHOD X, we get the accuracy, ease of use, and a cohesive ecosystem that delivers professional results—fast.”

Explore how METHOD Pro Series customers are turning ideas into impact—across industries, materials, and missions.

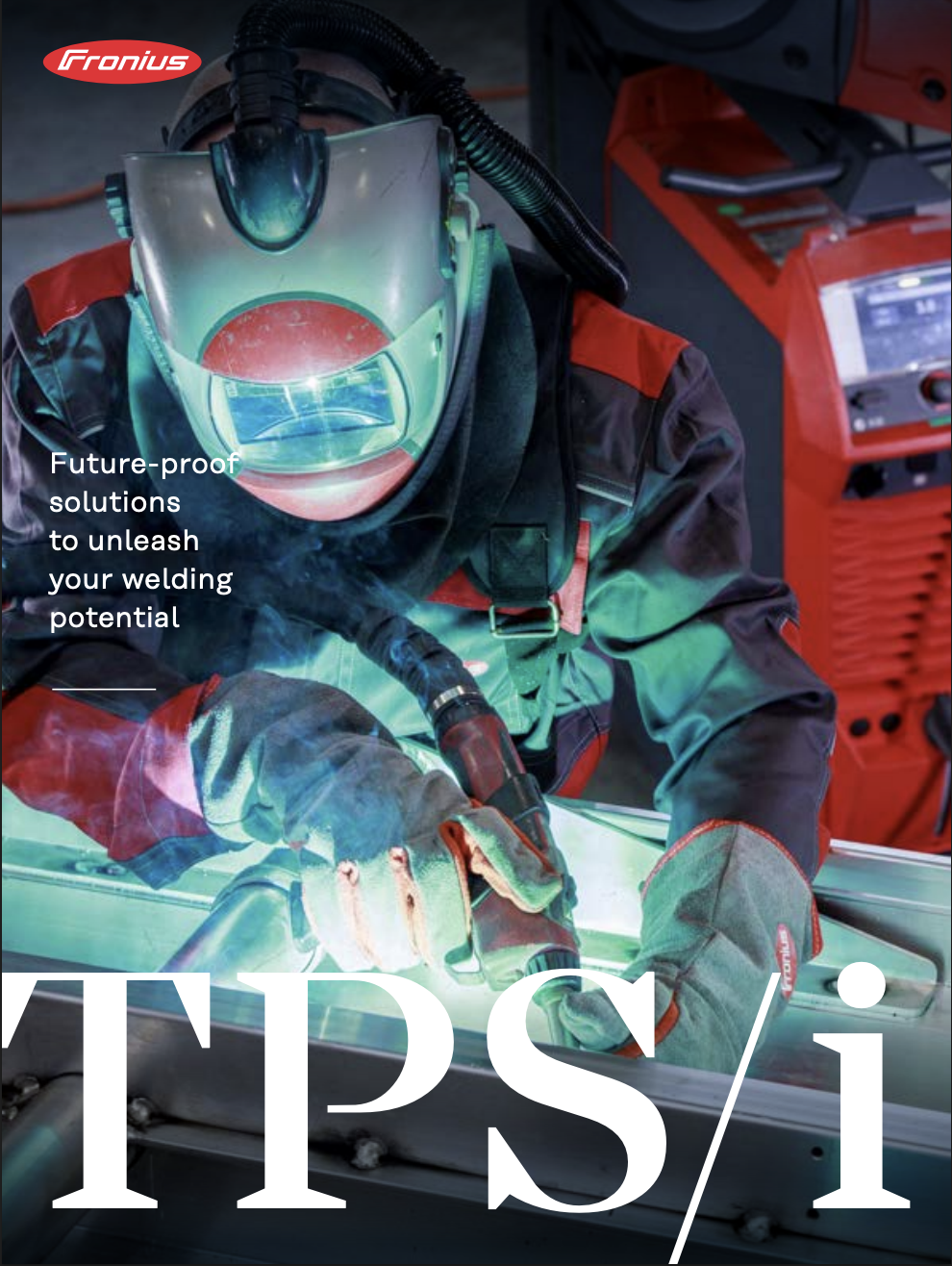

The Fronius TPS/i series sets the standard for intelligent, high-performance robotic welding. With models ranging from 320 to 600 amps and advanced features like arc length stabilization, touch-screen controls, and modular expandability, TPS/i is engineered to meet the highest demands for steel, stainless steel, and aluminum welding. When paired with APT’s FANUC robotic welding carts, this solution offers unmatched flexibility and seamless automation for educational and industrial training environments.

Advanced welding software packages—including LSC (Low Spatter Control), PMC (Pulse Multi Control), and CMT (Cold Metal Transfer)—enable a wide range of materials and welding positions with precision, repeatability, and reduced heat input. Combined with intuitive operation and future-ready digital connectivity via WeldCube, the TPS/i is a powerhouse platform that prepares students and trainees for the real-world demands of Industry 4.0 manufacturing.

Discover why the Fronius TPS/i is a leading choice for advanced welding training and robotic integration. With power levels up to 600 amps, modular software packages, and seamless compatibility with APT/FANUC robotic welding carts, the TPS/i delivers performance, precision, and future-ready flexibility. Whether you're teaching students in a CTE program or upskilling your workforce, this system adapts to real-world demands in steel, stainless steel, and aluminum welding applications.

Why Choose the TPS/i Series?

- High-performance output: Available in 320, 400, 500, and 600 A configurations

- Modular and upgradeable: Expand with welding packages like LSC, PMC, and CMT

- Touchscreen interface: 7" color display with intuitive, glove-friendly operation

- Precision welding: Intelligent arc length and penetration stabilizers

- Software integration: Compatible with WeldCube for performance monitoring and training

This brochure provides a full overview of system capabilities, supported processes, hardware configurations, torch packages, and digital control features—making it a valuable resource for welding educators, program coordinators, and industrial training managers.

The Fronius PMC (Pulse Multi Control) welding package transforms the standard pulsed arc into a high-precision, high-speed process with optimized arc length and penetration stabilizers. Designed for maximum control and minimal spatter, PMC supports both manual and robotic welding, producing high-quality, repeatable results even in vertical and overhead positions.

With features like spatter-free ignition (SFI), TIG-like seam appearance, and improved productivity across steel, aluminum, and galvanized applications, PMC is ideal for advanced welding environments. Download the brochure to explore how PMC outperforms standard pulse and LSC processes—helping you reduce energy use, material waste, and rework.

Pages

-

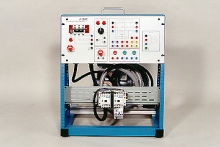

Item Number:421-000DAC Worldwide’s 1-Phase Motor Control Training System with Magnetic Starter (421-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial single-phase, magnetic motor starters.

-

Item Number:420-000DAC Worldwide’s 1-Phase Motor Control Training System with Manual Starter (420-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial single-phase, manual (across the line) starters.

-

Item Number:273-907DAC Worldwide’s 100A, Single Pole Circuit Breaker Cutaway (273-907) is a detailed and professionally-crafted circuit breaker cutaway that depicts a common DIN-rail-mounted, single-phase industrial breaker. T

-

Item Number:2FG7OnRobot's 2FG7 Finger Gripper is a complete, low-cost, off-the-shelf electric parallel gripper that can be deployed on any major collaborative or light industrial robot within minutes and requires no custom engineering for installation, programming, or maintenance.

-

Item Number:2FGP20The OnRobot 2FGP20 electric gripper offers a wide stroke and customizable arms to easily handle containers that can’t be handled with traditional vacuum grippers. Like all OnRobot electric grippers, the 2FGP20 provides fast, out-of-the-box deployment with intuitive programming.

-

Item Number:206-000Basic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

-

Item Number:206-PACBasic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

-

Item Number:423-000DAC Worlwide’s 3-Phase Motor Control Training System with Magnetic Starter (423-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic starters.

-

Item Number:424-000DAC Worldwide’s 3-Phase Motor Control Training System with Magnetic Starter, Low Voltage Start (424-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic starters.

-

Item Number:422-000DAC Worldwide’s 3-Phase Motor Control Training System with Manual Starter (422-000) is a task-specific, motor control-related training device that allows for skill-building in the operational principles, circuit design, wiring, fault troubleshooting, and application of industrial three-phase, manual motor starters.