Liquid–Liquid Separation for Education & Research

From Theory to Application: Extraction Education

Liquid–liquid extraction is a versatile separation technique, commonly applied in pharmaceuticals, environmental engineering, and chemical production. Pignat extraction units give students a hands-on platform to explore solvent recovery, phase equilibria, and distribution coefficients.

By operating real equipment, learners connect theoretical concepts to industrial practices, gaining valuable process engineering skills.

Key Learning Outcomes

- Understand phase equilibria in liquid–liquid systems

- Perform separation and purification through extraction

- Study solvent recovery and distribution coefficients

- Apply liquid–liquid extraction to real industrial challenges

Explore Solid–Liquid Separation Hands-On

Pignat Filtration Systems for Education & Research

Filtration is a core separation method across industries, from chemical production to environmental management. Pignat’s filtration training units let students experiment with solid–liquid separation, pressure effects, and filtration media.

These systems prepare learners for real-world challenges by linking academic knowledge with industrial filtration applications.

Key Learning Outcomes

- Study the mechanics of solid–liquid separation

- Understand the impact of pressure and media type

- Evaluate efficiency and product quality

- Apply filtration principles to chemical and environmental processes

Pignat Reaction Training Units for Education

Hands-On Training in Chemical Kinetics

Reaction engineering is the foundation of chemical process design. Pignat’s reaction training systems enable students to explore kinetics, reactor operation, and process optimization in a controlled lab setting.

These systems reinforce critical concepts in chemical engineering, preparing learners to design and scale up industrial processes effectively.

Key Learning Outcomes

- Understand chemical kinetics and reaction rates

- Explore different reactor designs and configurations

- Study process optimization and operating parameters

- Apply reaction engineering concepts to industrial challenges

Amatrol T7022 EV-Battery Technology Fundamentals Learning System

The Amatrol T7022 EV-Battery Technology Fundamentals Learning System provides a comprehensive introduction to electric vehicle battery systems, combining theory with hands-on practice. Learners gain real-world experience in safety, diagnostics, charging, and storage through interactive training modules designed for workforce readiness.

Hands-On Training with Real Components

This training workstation features authentic EV battery system components, including lithium-ion batteries, a smart charger/discharger, an individual cell charger, battery storage unit, electrical circuit devices, and a thermal camera. These tools ensure students practice with the same technologies used in industry settings.

Skills Covered

- Introduction to electric vehicle systems

- Basic circuit concepts: voltage, current, and resistance

- Circuit protection methods

- Lithium-ion battery characteristics and operation

- Battery charging, handling, and storage

- Battery packs and life cycles

- Battery production and testing

- EV electrical system operation

Key Learning Features

- 29 Hands-On Skills: From cell testing to smart charging and troubleshooting.

- Multiple Power Options: Includes individual batteries, packs, and 12VDC supply.

- Safety-Focused: Battery circuit breakers, storage, and low-current lithium-ion phosphate batteries.

- Interactive Curriculum: Multimedia eLearning with 3D graphics, quizzes, and simulations.

Industry-Relevant Training

With growing demand for EV technicians, the T7022 delivers the skills employers require. By learning to operate smart chargers, analyze battery packs, and apply safety protocols, students graduate with the technical confidence to enter EV and advanced transportation careers.

Tech-Labs proudly offers Amatrol’s EV-Battery Technology Fundamentals Learning System to schools, colleges, and workforce training centers.

Contact us today to integrate EV battery training into your technical program.

Pages

-

DAC Worldwide’s selection of furniture offers a variety of solutions for creating flexible and functional training areas. Designed to work with DAC Worldwide's training systems, cutaways, models, and dissectibles, available furniture options allow you to create workstations, displays, or storage areas.

-

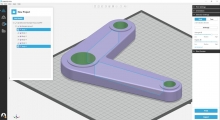

GrabCAD Print is a complete solution for Stratasys 3D printers. The intuitive, easy-to-use software simplifies preparing, scheduling, monitoring, and reporting print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management.

-

Item Number:400-PAC

DAC Worldwide’s Basic Electricity Training System Plus (400-PAC) examines basic AC and DC electrical principles. Learners will explore how electricity is used for power and control in various sectors, including industrial, commercial and residential applications. The training covers industry-relevant skills, such as installing, operating, and troubleshooting AC and DC electrical circuits in a variety of applications.

-

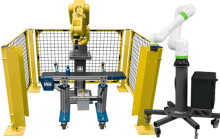

Safety fencing, conveyors, robot pedal stools, and CRX mobile carts