System Overview and Compatibility

ABS-CF10 is currently available on the F123™ Series machines with 0.007 inch (0.178 mm), 0.010 inch (0.254 mm), and 0.013 inch (0.33 mm) layer heights. It requires a dedicated ABS-CF10 extrusion head, denoted with a dark green case, for all layer heights for the model material. It is compatible with QSR Support™ as a soluble support system and requires a standard F370™ extrusion head for all layer heights for the support material. This system uses the standard F123 Series build tray. ABS-CF10 and QSR are available in a standard F123 90-cubic-inch spool.

Stratasys ABS-CF10 combines standard ABS (acrylonitrile butadiene styrene) material with 10% chopped carbon fiber by weight.

The result is a low moisture-sensitive FDM® thermoplastic 50% stiffer and 15% stronger than standard ABS 3D printing material.

Typical applications include manufacturing tools, jigs, fixtures and end effectors that benefit from the combination of increased stiffness and reduced weight.

Diran™ 410MF07 is a nylon-based thermoplastic FDM® material, mineral-filled 7% by weight. It demonstrates very good toughness and impact strength combined with resistance to hydrocarbon-based chemicals. Its smooth, lubricious surface quality offers low sliding resistance.

Typical applications include jigs, fixtures and other forms of general manufacturing tooling, and is particularly effective for applications needing a non-marring interface between the tool and the workpiece.

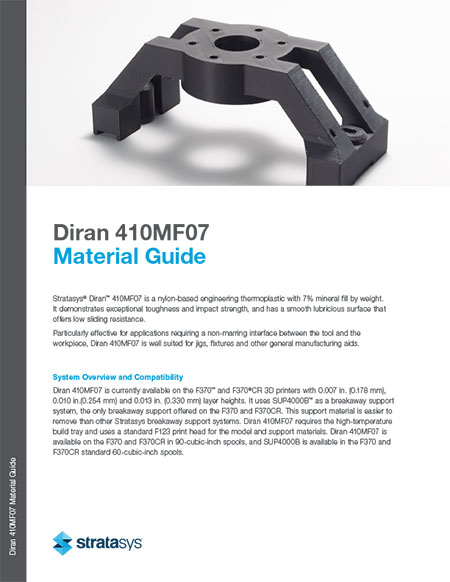

Stratasys® Diran™ 410MF07 is a nylon-based engineering thermoplastic with 7% mineral fill by weight. It demonstrates exceptional toughness and impact strength and has a smooth lubricious surface with low sliding resistance.

Particularly effective for applications requiring a non-marring interface between the tool and the workpiece, Diran 410MF07 is well suited for jigs, fixtures, and other general manufacturing aids.

System Overview and Compatibility

Diran 410MF07 is currently available on the F370™ and F370®CR 3D printers with 0.007 in. (0.178 mm), 0.010 in.(0.254 mm) and 0.013 in. (0.330 mm) layer heights. It uses SUP4000B™ as a breakaway support system, the only breakaway support offered on the F370 and F370CR. This support material is easier to remove than other Stratasys breakaway support systems. Diran 410MF07 requires the high-temperature build tray and uses a standard F123 print head for the model and support materials. Diran 410MF07 is available on the F370 and F370CR in 90-cubic-inch spools, and SUP4000B is available in the F370 and F370CR standard 60-cubic-inch spools.

Overview of Stratasys FDM 3D Printers and Materials

FDM® (fused deposition modeling) 3D printers offer unparalleled versatility to turn your CAD files into durable parts. These parts are tough enough to be used as advanced conceptual models, functional prototypes, manufacturing tools, and production parts. Engineers can produce various products just by loading different files and materials. No traditional machining process can do that.

Handling & Finishing ABS-ESD7 Parts

Overview

ABS-ESD7 (static dissipative) material is among the many great materials available for the Fortus systems. This paper will walk you through the handling considerations for ABSESD7, including finishing, safety, and packaging guidelines.

Finishing

This material's most common finishing techniques are bonding and smoothing. For smoothing, sanding is the recommended method. As with all FDM materials, standard sanding processes can be followed. Unlike our standard ABS materials, note that this material cannot be smoothed using the finishing touch station. ABS-ESD7 can easily bond through typical methods, including solvents, epoxies, hot-air welding, ultrasonic welding, and superglue.

ABS-ESD7™ (acrylonitrile butadiene styrene-electrostatic dissipative) is an ABS thermoplastic with static dissipative properties suited for static discharge-sensitive applications. ABS-ESD7 prevents static electricity buildup, so it will not produce a discharge or attract other materials like powders, dust, and fine particles.

The material is ideal for jigs and fixtures used to fabricate and assemble electronic components and associated production line and conveyor parts. It is also useful for producing functional prototypes, enclosures, and packaging.

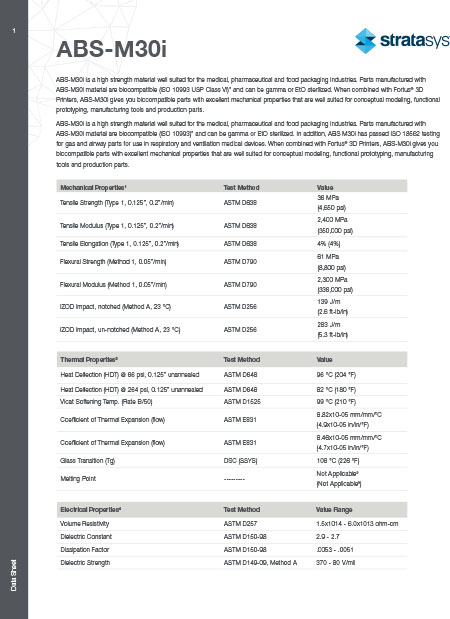

ABS-M30i is a high-strength material well-suited for the medical, pharmaceutical and food packaging industries. Parts manufactured with ABS-M30i material are biocompatible (ISO 10993)* and can be gamma or EtO sterilized. In addition, ABS M30i has passed ISO 18562 testing for gas and airway parts for use in respiratory and ventilation medical devices. When combined with Fortus® 3D Printers, ABS-M30i gives you biocompatible parts with excellent mechanical properties well suited for conceptual modeling, functional prototyping, manufacturing tools and production parts.

Antero™ 840CN03 is a PEKK-based FDM thermoplastic combining the excellent physical and mechanical qualities of PEKK with electrostatic dissipative (ESD) properties. The material is filled 3% by weight with carbon nanotubes.

As a high-performance polymer, Antero 840CN03 exhibits exceptional chemical and wear resistance, ultra-low outgassing properties and consistent ESD performance. ESD values range from 104 – 109 ohms per square inch. This makes the material particularly suitable for space and industrial applications where these qualities are critical.

Pages

-

A large working envelope with a reach of 717 mm, and a payload of 7 kg, combine to provide solutions for high productivity handling and assembly applications.

-

With FANUC Robotics’ CERT Program, new courses and project based activities prepare students for a workplace that will be increasing in robotic automation. The Fanuc Robotics Education Training Cart incorporates the compact M-1+A robot housed in a self contained, mobile enclosure. The lightweight parallel-link M-1+A robot is designed for small part handling, high speed picking and assembly applications.

-

FANUC America now offers Certified Education Robot Training (CERT) to qualifying High Schools, Community Colleges, and Universities. With FANUC America's educational robots, students can learn to utilize the latest automation technology while applying Science, Technology, Engineering, and Math. Industrial robotics training in the classroom can safely be achieved through the CERT program. FANUC America provides the necessary training to the instructor as well as a curriculum to introduce students to robot applications.

-

Item Number:D73F-0320-PB00Experience the cutting-edge in CNC machining simulation with FANUC's D73F-0320-PB00 simulator. Equipped with real kinematics, live machine movement, and advanced features like collision detection, immerse yourself in a true-to-life machining experience. Discover the power of virtual milling or lathe operations with our software-only version for seamless integration. Get ready to revolutionize your CNC training!

-

Item Number:CR-7iA/LAllows for a collaborative operation with human operators due to no need of safety fences, and enables to locate the robots close together in the manufacturing processes where operators also work, with using the compact size.

-

FANUC CRX-5 Fenceless Cart – a collaborative robot solution with steel or aluminum cart options, integrated iRVision, and industry-leading safety features for flexible automation in education and industry.

-

Item Number:FANUC ER-4iADesigned with students in mind, this all-in-one robotics-training bundle enables individuals to gain first-hand experience of programming and operating cutting-edge industrial robots. Package content is highly relevant for modern factory applications and contains everything instructors require to teach students to program and operate robots.

-

The FANUC Fenceless Collaborative Cert Cart was developed by combining FANUC DCS Position and Speed Check software with an Allen Bradley SafeZone Mini Safety Laser Scanner. The result is FANUC’s NEW FENCELESS CERT Cart, which still fits through a standard door and runs off 110V power. The FENCELESS cart allows a greater work envelope and introduces students to the latest integrated safety products from FANUC and Allen Bradley.

-

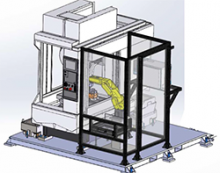

Students trained on ROBODRILL products will be more productive. Excellent repeatability makes the ROBODRILL suited for milling, drilling, tapping, and boring with flexibility, versatility, and reliability. Specific ROBO DRILL education packages have been configured for the needs of educational institutes teaching 3-axis and 5-axis machining, robotic machine tending, and Connected Smart Manufacturing (CSM).

-

Item Number:α-D14MiBThe new-generation FANUC ROBODRILL promises unrivaled quality and precision at great hourly rates. At the heart of every ROBODRILL is a patented high-speed tool changer that can carry 21 tools and offers the best reliability in its class.