High-Fidelity Boom Truck Simulation for Crane Operator Training

The CM Labs Boom Truck Simulator Training Pack delivers industry-leading realism in crane operation training. Developed with input from leading OEMs and training organizations, this simulation solution replicates hydraulics, engine behavior, boom deflection, and cable dynamics—ensuring that learned skills directly transfer to real-world operation.

Featuring a progressive curriculum and exercises from beginner to advanced levels, trainees learn to deploy outriggers, control loads, and manage hoisting operations—all while preparing for industry certifications like CCO. Safety and efficiency are built into every session, with real-time performance tracking and customizable metrics that give instructors full visibility into each operator’s progress.

The Boom Truck Simulator supports immersive training on CM Labs’ full line of hardware platforms, including Vortex Edge Plus, Edge Max, and Advantage. Ideal for utilities and lifting professionals, this simulation pack integrates seamlessly with other CM Labs lifting equipment to provide a complete training ecosystem.

Compact Track Loader Simulation for Entry-Level Equipment Operator Training

CM Labs’ Compact Track Loader (CTL) Simulator Training Pack is the ideal entry point for developing equipment operator skills in a safe, realistic environment. Designed to reduce tipping incidents and other operator risks, this pack replicates machine stability with unrivaled accuracy—empowering trainees to develop confidence and efficiency from day one.

Through progressive exercises, users master tasks such as load handling, excavating, trailer loading, and grading. With attachments like forks and buckets included, learners gain hands-on familiarity with multi-functional equipment. CM Labs’ patented Smart Training Technology™ delivers authentic machine feedback, simulating everything from gear shifting to throttle control and cycle time efficiency.

Trainers benefit from real-time metrics tracking safety violations, cycle times, and task completion. Optional features like weather events and fault insertion add realism to every session. The CTL Training Pack runs on all Vortex simulator platforms—Edge Plus, Edge Max, and Advantage—offering flexible deployment for schools and training centers of all sizes.

Digger Derrick Operator Training with Realistic Drilling and Pole Handling Simulation

The Intellia Digger Derrick Simulator Training Pack from CM Labs is the only simulation-based solution dedicated to mastering the specialized tasks of pole setting and drilling. Built with CM Labs' award-winning simulation technology, this training pack recreates every element of the machine—hydraulics, boom deflection, cables, auger torque, and tipping risk—to deliver authentic, high-impact training for utility operators.

Designed to build skill and safety awareness progressively, this solution supports certification prep for both EICA and CCO exams. Trainees move through guided lessons, including augering holes, placing poles, and performing precision lifts using real-world techniques and challenges. Trainers benefit from over 20 tracked performance metrics, such as idle time, collisions, engine RPM, and fuel usage, allowing for highly tailored feedback.

Compatible with the Vortex Edge Plus, Edge Max, and fully immersive Advantage platforms, the Digger Derrick Simulator integrates seamlessly into a comprehensive training program. With enhanced tools for instructors—including customizable learning paths, weather and fault simulation, and performance reporting—this solution takes safety-focused utility training to the next level.

Realistic Dozer Training Simulation for Excavation and Grading

The Intellia Dozer Simulator Training Pack from CM Labs delivers a comprehensive learning experience for heavy equipment operators. Built with Smart Training Technology™, the simulator replicates true dozer behavior—from blade control to soil resistance—giving trainees the ability to practice excavation, fine grading, and access road creation in a safe, controlled setting.

Trainees progress through a series of increasingly complex scenarios, including walkaround inspections, dump truck positioning, trailer loading, and trench excavation. The system promotes proper techniques with a 6-way blade and engages a virtual engine and transmission the moment the blade hits soil, teaching real-world operating feel.

Performance metrics such as cycle time, idle time, blade efficiency, and safety violations are tracked in real time. Trainers can use CM Labs' optional Intellia Instructor software to manage student progress, introduce fault conditions, and simulate various weather challenges. Compatible with Vortex Edge Plus, Edge Max, and Advantage hardware platforms, this training solution helps organizations reduce risks and maintenance costs while building confident, capable operators.

Forklift Simulation Training for Safe, Skilled Material Handling

The CM Labs Forklift Simulator Training Pack delivers a high-impact learning experience designed to build operator competency and reduce workplace incidents. With accurate forklift dynamics—including instability during tight turns, slope driving, and load braking—trainees are immersed in realistic scenarios that reflect real-world challenges.

From basic maneuvers to complex load handling in confined spaces, learners gain hands-on experience in a range of indoor and outdoor environments populated with racks, pedestrians, power lines, and ramps. The simulator integrates visual aids like the stability triangle, rear-view camera, and a mini-map to improve situational awareness and decision-making.

Progressive learning exercises are complemented by detailed performance metrics such as overturns, major collisions, and load contact violations. Certification prep and freeform practice options help operators move beyond compliance into true proficiency. The Forklift Simulator runs on the portable Vortex Edge Plus and motion-enabled Vortex Edge Max, offering flexible deployment for any training program.

Mini Excavator Training with Real-World Utility Safety Scenarios

CM Labs’ Mini Excavator Simulator Training Pack is the first solution of its kind to focus on the unique operating challenges of compact utility equipment. Designed for safety and realism, the simulator replicates everything from tipping behavior and vibration to underground utility line interaction—making it an ideal tool for training safe, confident operators in high-risk utility environments.

Trainees advance through a progressive curriculum that covers walkaround inspections, controls familiarization, digging around underground lines, and loading/unloading from trailers. Real-time teachable moments provide feedback to prevent negative habits, and a freeform sandbox encourages exploration and problem-solving.

Supported by CM Labs’ Smart Training Technology™, the simulation captures critical performance metrics like utility strikes, vehicle tip-overs, idle time, and soil spillage. Compatible with Edge Plus, Edge Max, and Advantage platforms, the Mini Excavator Simulator is part of CM Labs’ comprehensive utility training ecosystem, which also includes digger derricks and boom trucks.

Rough Terrain Crane Simulation for Realistic Rough Terrain Operator Training

The CM Labs Rough Terrain Crane Simulator Training Pack prepares operators for the most demanding lifting scenarios—from complex tandem lifts to navigating confined spaces near power lines. With highly accurate boom dynamics, cable behavior, and crane controls, trainees experience every nuance of mobile crane operation in a safe, repeatable environment.

The simulator’s progressive curriculum teaches load charts, LMI configuration, hook and pendulum control, and lift plan execution. Trainees gain hands-on experience in tasks like working inside buildings, changing parts-of-line, and performing CCO test courses. Built-in scoring tracks metrics such as pendulum time, rough load handling, and safety violations, giving instructors actionable insights.

CM Labs’ patented Smart Training Technology™ delivers a mechanical simulation layer that replicates engine torque, transmission, tire deformation, and lift response. The Mobile Crane Training Pack is compatible with all Vortex hardware configurations, and can be paired with the Signal Person Station for team-based learning in complex virtual jobsites.

Immersive Tracked Excavator Training with Trimble® Grade Control

The Intellia Tracked Excavator Simulator Training Pack by CM Labs delivers a highly immersive experience that builds real-world skills in trenching, load handling, and precision excavation. Trainees engage in a virtual jobsite equipped with Trimble® Earthworks technology, replicating real machine operation while building efficiency and safety awareness.

This training pack emphasizes the three pillars of expert operation—safety, technique, and efficiency. Exercises include everything from walkaround inspections and boom/stick control to pipe placement and bench loading. Trainees also practice working around personnel and power lines, with real-time tracking of movement accuracy, idle time, bucket fill percentage, and safety violations.

The simulator uses CM Labs’ industry-leading Smart Training Technology™ to create the most realistic soil simulation and machine response available. With customizable environmental settings, instructors can simulate weather changes and low-light scenarios for added challenge. Compatible with all CM Labs platforms (Edge Plus, Edge Max, Advantage), this solution ensures safe, scalable excavator training for schools, unions, and contractors alike.

Full-Scope Wheel Loader Training for Safe and Productive Operations

The Intellia Wheel Loader Simulator Training Pack from CM Labs delivers realistic, high-impact training for core earthmoving tasks. Whether you're stockpiling materials, transporting loads, or mastering truck loading, this simulator builds true-to-life skills with zero wear and tear on actual equipment.

Trainees progress through a comprehensive learning path that covers controls familiarization, bucket positioning, material transport, and safe load handling. Built on CM Labs’ award-winning Smart Training Technology™, the simulator offers precision hydraulic behavior, terrain response, and soil flow physics—giving operators the authentic “feel” of the job.

Performance data such as fuel consumption, cycle time, idle time, and collision tracking provide measurable insights for instructors. Compatible with Edge Plus, Edge Max, and Advantage platforms, the Wheel Loader Training Pack also includes quick coupler functionality and multiple attachments like forks and a truss boom. It’s the perfect tool for preparing operators for the rigors of real-world job sites.

CM Labs proudly introduces the Intellia Mini Excavator Simulator Training Pack, the first of its kind in the industry. Developed to meet the increasing complexity of modern jobsites, this immersive training solution sets a new standard for safety and operator readiness. With built-in scenarios addressing critical issues like underground utility line work, this simulator enables learners to train in high-risk environments—without the actual risk.

Designed for both novice and experienced operators, the Mini Excavator Simulator blends authentic machine behavior with real-world terrain challenges, providing a comprehensive training pathway. From walkaround inspections to advanced control techniques, users gain valuable experience in a highly realistic environment. With no wear and tear on physical equipment and enhanced safety outcomes, training programs can scale more efficiently than ever before.

Pages

-

Item Number:ILS12.150DThe ILS12.150D is a free-standing platform with a materials processing envelope of 48" x 24" x 12" or 13,824 in³. The dual laser platform supports a power range of 10 to 150 watts (up to 75 watts with one 10.6µm CO2 laser; up to 150 watts with a second 10.6µm CO2 laser). The ILS12.150D also supports a single 9.3µm laser at 30, 50 or 75 watts (If a 9.3µm CO2 laser is installed, the maximum 10.6µm laser is 75 watts).

-

Item Number:ILS12.75The ILS12.75 is a free-standing platform with a materials processing envelope of 48" x 24" x 12" or 13,824 in³. The single laser platform supports either one 10.6µm CO2 laser (10 to 75 watts) or one 9.3µm CO2 laser (30, 50 or 75 watts).

-

Item Number:ILS9.150DThe ILS9.150D is a free-standing platform with a materials processing envelope of 36” x 24” x 12” or 10,368 in³. The dual laser platform supports a power range of 10 to 150 watts (up to 75 watts with one 10.6µm CO2 laser; up to 150 watts with a second 10.6µm CO2 laser).

-

Item Number:ILS9.75The ILS9.75 is a free-standing platform with a materials processing envelope of 36” x 24” x 12” or 10,368 in³. The single laser platform supports either one 10.6µm CO2 laser (10 to 75 watts) or one 9.3µm CO2 laser (30, 50, or 75 watts).

-

Item Number:iLSEach base can hold up to 12 modules to accommodate multiple applications and/or multiple students while still fitting through a standard doorway.

-

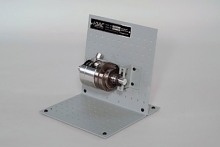

Item Number:200-2202DAC Worldwide’s In-Line Friction-Type Pneumatic Clutch Cutaway (200-2202) depicts a sectioned industrial pneumatically-activated, spring-return, in-line, friction-type clutch for use in a classroom and laboratory training related to mechanical drives.

-

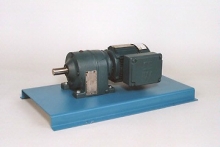

Item Number:205-230In-line helical gear reducers have a unique set of benefits. They’re useful in higher horsepower applications where long-term efficiency is more important than initial costs, which can be higher for this type of gear reducer (although in-line reducers are less expensive than parallel shaft reducers).

-

Item Number:205-130The In-Line Helical Gear Reducer Dissectible is a sturdy unit mounted on a 7-gauge, formed-steel baseplate with provision for bench-top, workstation, or storage rack mounting.

-

Item Number:205-255In-line helical gear reducers have a unique set of benefits. They’re useful in higher horsepower applications where long-term efficiency is more important than initial costs, which can be higher for this type of gear reducer (although in-line reducers are less expensive than parallel shaft reducers). In addition to being highly efficient, in-line helical gear reducers are capable of handling higher overhung loads.

-

Item Number:205-285DAC Worldwide's In-Line Planetary Gear Reducer Cutaway (205-285) is a sectioned industrial gear reducer for use in classroom and laboratory training relating to mechanical drives.