Mechatronics Sorting and Buffering

Amatrol’s Mechatronics Sorting-Buffering Learning System (87-MS4) is training mobile workstation 4 of the 870 Mechatronics Learning System. The 87-MS4 station is a small Mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other stations. In efforts to protect workers and machines, industrial safety and operation are emphasized on all Amatrol Mechatronic stations.

The Sorting-Buffering training station teaches interfacing, problem solving, programming, sequencing and operation for sorting, queuing, flat belt conveyors, photoelectric sensors, and inductive sensors. This station performs the role of sorting parts by material type in the process of assembling a working industrial control valve.

The 87-MS4 is a mobile workstation with slotted work surface that contains an operator station, belt conveyor module, part sorting module, buffer module, proximity sensing module, parts set, a pneumatic distribution module as well as an electrical distribution module, an electro-pneumatic valve manifold, and a digital I/O interface module.

Mechatronics Robotic Assembly

Amatrol’s 87-MS5-P2, Servo Robotic Assembly – Pegasus II, is station 5 of the 870 Mechatronics Learning System. The 87-MS5-P2 station is a small Mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other stations. Industrial safety and operation are emphasized on all Amatrol Mechatronic stations. The Servo Robotic Assembly station trains students for pick and place assembly, and teaches interfacing, problem solving, programming, sequencing and operation for servo robotics, gravity feeders, pneumatic screw feeders, and part insertion. This station performs the role of assembling a working industrial directional control valve using a combination of servo robotic and pick and place technologies.

The 87-MS5-P2 has two mobile training workstations with slotted work surfaces that contain an operator station, Pegasus II servo robot with teach pendant, spool insertion module, screw feed module, spring/knob feed module, screw/knob engagement module, assembly shuttle module, parts presentation module, finished parts storage module, parts set, a pneumatic distribution module as well as an electrical distribution module, an electro-pneumatic valve manifold, and a digital I/O interface module.

Interfacing, Programming & Sequencing

Amatrol’s 87-MS6, Torque Assembly, is mobile training station 6 of the 870 Mechatronics Learning System. The 87-MS6 station is a small Mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other training work stations. Industrial safety and operation are emphasized on all Amatrol Mechatronic stations.

Mechatronics Technician Training

Amatrol’s Automated Inventory Storage System (87-MS7) is the seventh station of the 870 Mechatronics Learning System and allows learners to gain valuable skills used in inventory storage processes by studying operation, adjustment, and programming of an inventory storage system. This learning system will allow learners to practice and study operating a programmable parts storage station, adjusting a phototransistor optical interrupter switch, and designing a PLC program that provides manual/auto/reset functions for a programmable parts storage station.

This mechatronics learning system features real-world components like infrared sensors, pneumatic grippers and brakes, pick and place storage and more! Learners will use these and other components to practice mechatronics safety, torque clamp module sequencing, station operation, and non-servo electric slide sequencing. Amatrol uses components that learners will find on-the-job in order to give the best opportunity to build confidence and industrial competencies.

CNC Programming Training

The Mechatronic CNC Mill Training System (87-MS8M60) allows learners to use a Denford CNC Micromill in conjunction with Amatrol’s Mechatronics Servo Robotic Assembly Station (87-MS5-P2). This combination provides hands-on practice for incorporating machining and CNC Mill integration within an automated lines process. In addition to integrated automation/machining skills, learners will study about CNC programming fundamentals. Because CNC mills are used to create a variety of parts and components, learners entering the manufacturing industry will find this learning system’s hands-on practice and real-world skills invaluable.

This system includes a variety of real-world components including a Denford Micromill, mobile workstation, electro-pneumatic vise with filter/regulator, tooling package, robot-to-CNC interface, and an electro-pneumatic chip blower. The 87-MS8M60 also features world-class interactive multimedia curriculum, an install guide, and a student reference guide.

Amatrol’s Mechatronics Electro-Hydraulic Training Station (87-MS9) allows learners to gain valuable product testing skills used in automated processes by studying topics like station operation and adjustment, module sequencing, and station sequencing. This learning system will allow learners to practice and study how products are tested on an automated line, how these skills are integrated within a larger automated process, and an example of how hydraulics are utilized on an automated line.

The 87-MS9 requires either an Allen-Bradley CompactLogix or Siemens S7300 Mechatronics Learning System (870-MPC) and integrates seamlessly with Amatrol’s full Mechatronics System or can be used with just the Torque Assembly (87-MS6) and Inventory Storage (87-MS7) Stations.

Allen-Bradley and Siemens PLCs

87-MSSAB12, 87-MSSAB53, 87-MSSAB53A, 87-MSSS7

Amatrol's MechaSIM Mechatronics Simulation Learning Systems (87-MSS) allow learners to study programs for Allen-Bradley and Siemens PLCs and then use those programs to run real-world applications in a simulated mechatronics environment. Learners can then use the programs to control actual mechatronics equipment after testing it in the simulation. Amatrol offers MechaSIM systems for the following controlers: AB CompactLogix L32 and L16, AB MicroLogix, and Siemens S7-300. These MechSIM systems can interface to any of Amatrol's Mechatronics carts.

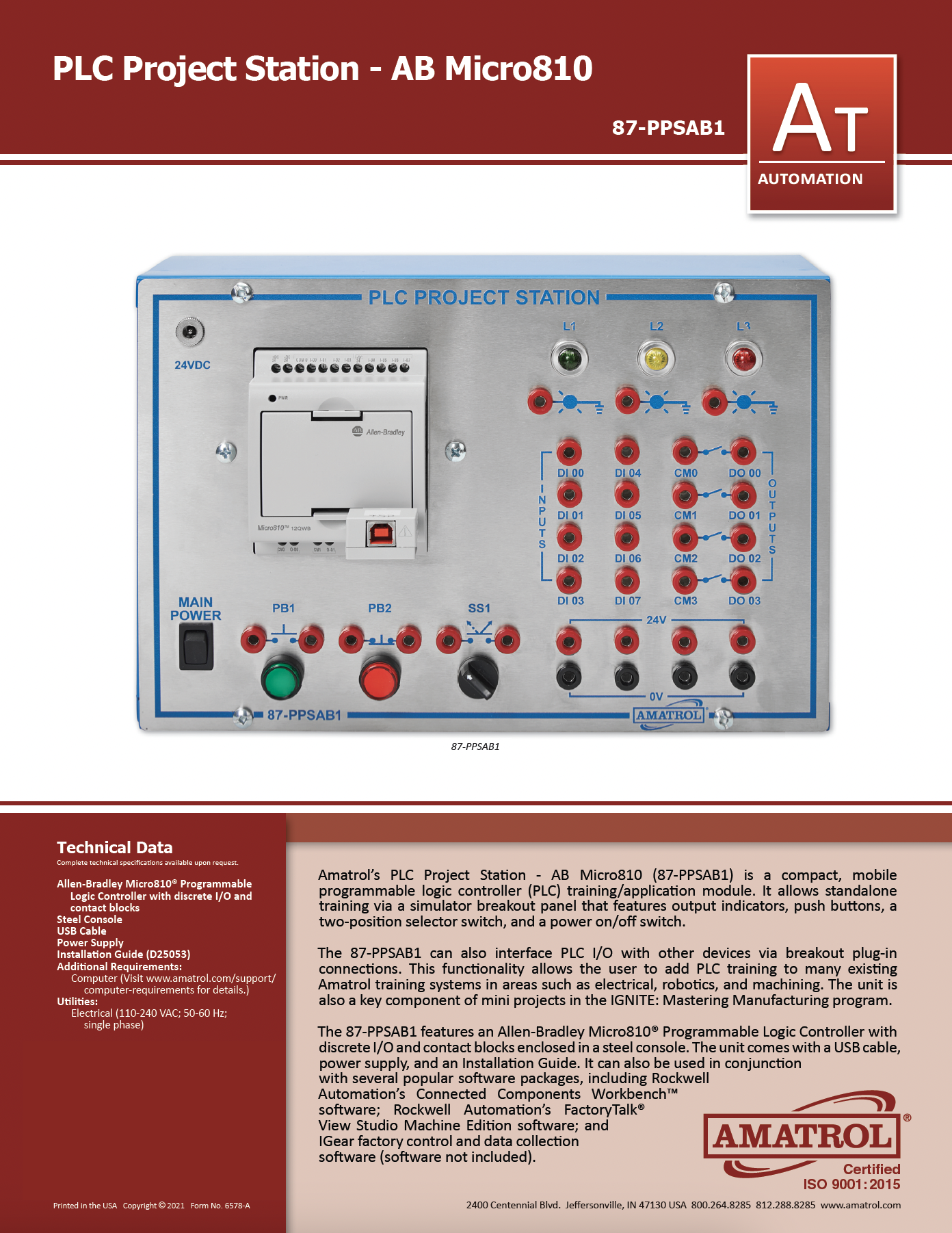

Amatrol’s PLC Project Station – AB Micro810 (87-PPSAB1) is a compact, mobile programmable logic controller (PLC) training/application module. It allows standalone training via a simulator breakout panel that features output indicators, push buttons, a two-position selector switch, and a power on/off switch.

Amatrol’s Servo Robot Station for Tabletop Mechatronics (87-TMS4) provides robot integration for Table Top Mechatronics with the Pegasus servo robot mounted on a traverse. Fully supported by Amatrol’s curriculum, learners will practice robot programming and robot interfacing to Amatrol’s portable Mechatronics system to create applications such as a robot-based inventory station. The ability to expand a Tabletop Mechatronics system to include a servo robot is unmatched in the industry.

To update the Tabletop Mechatronics System for operation with the Pegasus robot, this robot integration package includes three conveyor chute assemblies and a feeder assembly all equipped with sensors. These sensors are wired to the Mechatronics system’s PLC to indicate when parts are present. Additionally, this system contains replacement foot supports, used to adjust system height, and other items required to interface the servo robot and servo traverse to Tabletop Mechatronics.

AB CompactLogix L16 Learning System

Amatrol’s Vision Inspection Learning Systems (87-VS1AB53A) teach the use of web-based maintenance communications in a Smart Factory environment. These systems use a machine vision camera to examine parts traveling through the 870-series Mechatronics system and signal a PLC to reject or accept parts based on results from the examinations. The system can be used as a standalone product, but it is highly suggested for use with one or more Mechatronics carts.

The Smart Factory network communications training systems feature real-world equipment learners will encounter on the job, including configuring PC Vision Programming Software. The systems combine hands-on skills practice with in-depth multimedia curriculum for a well-rounded learning experience that will prepare learners to make an immediate impact in the technologically-advanced Smart Factory environments of the present and future through major topics like machine vision basics, machine vision operation, and machine vision software.

Pages

-

The FANUC Robot Integration Package (25098) allows customers to use a FANUC industrial robot with Amatrol’s 870-series mechatronics stations. This package contains a module enclosure that includes PLC and FANUC interface cables along with a customized program to integrate a customer-supplied FANUC robot with the mechatronics system. Additional features include customized gripper tooling and a safety guard assembly to protect learners.

-

The primary goal of this course is to teach workers safe work procedures to be aware of and mitigate warehouse fires in a warehouse environment. The Warehouse Fire Hazard Awareness simulation is ideal for employees or supervisors who work in or around warehouse operations.

-

Item Number:356DAC Worldwide’s Fire Tube Boiler Model (356) is a highly-detailed scale model of a common fire tube, Scotch marine boiler, supporting training in the operation and maintenance of industrial boilers, as found within utility systems in industrial facilities and large commercial applications.

-

Item Number:291DAC Worldwide’s Fired Heater Model (291) depicts a highly-detailed, to-scale model of a common industrial furnace found in refineries and process facilities in technically-accurate, professionally-crafted detail.

-

Train fire and EMS drivers safely with the Acron Aviation FireSim™ Series 8 Simulator. Includes emergency response scenarios, vehicle configuration options, and Replay Studio™ for after-action reviews.

-

The primary goal of this course is to teach workers the correct procedures to follow in a potential bloodborne pathogen event. The Bloodborne Pathogen VR simulation is ideal for future employees or supervisors who will work in hazardous environments where a potential bloodborne pathogen event may occur.

-

VR Hard Hat's First Aid: CPR & AED course aims to equip participants with the knowledge and hands-on skills required to effectively administer CPR and operate an AED during cardiac emergencies.

-

The Lucas-Nuelle training system allows first responders to practice the correct procedure for recovering hybrid and electric vehicles over and over again - until it becomes muscle memory, ensuring maximum efficiency even when working under time pressure.

-

Item Number:295-203DAC Worldwide's Fixed Head Bulk Storage Tank Model (295-203) is a highly detailed scale model of a conical-roof, fixed-head storage tank.

-

Item Number:226-000DAC Worldwide’s Flange Bolt Torquing (226-000) is a training package that includes a complete assortment of fixtures, tools, accessories, and technical data for training in proper bolt torquing using an eight-bolt pattern.