Amatrol’s Portable PLC Troubleshooting Learning System - AB CompactLogix (990-PABCL1F) provides comprehensive PLC operation and troubleshooting knowledge in a portable format for when training space is constrained, but skill-building cannot be sacrificed! Learners will study topics like programmable controller operation, PLC Ethernet communication, basic PLC project elements, PLC motor control, event sequencing, and more!

Combining training in areas such as programming, motor control, and pneumatics, the 990-PABCL1F offers learners the chance to operate the powerful Allen-Bradley L16ER CompactLogix 5370 PLC, PanelView 800 HMI terminal, and networks throughout the curriculum to build PLC training skills. The PLC training system’s interactive multimedia curriculum offers an unmatched breadth and depth of knowledge and skill-building. Only Amatrol can provide this level of training using a compact, portable workstation.

Amatrol’s Portable Process Control (990-PC1) covers two of the most common types of process control systems, flow and liquid level, by providing eLearning curriculum and hands-on training for subjects like process control equipment safety, loop controllers, level measurement and control, control loop performance, and more!

In this video, Amatrol answers a familiar question from those unfamiliar with industry: "What is process control?" This video gives a basic definition of process control, how and where it's utilized in industrial application, and how we can help with your process control training needs.

The Portable Process Control Troubleshooting Learning System – Level & Flow (990-PC1F) from Amatrol provides a portable troubleshooting training system for flow and liquid level, two of the most common types of process control systems. The system features eLearning curriculum and hands-on training for subjects like process control equipment safety, loop controllers, level measurement and control, control loop performance, and more.

Amatrol's 990-PC1F portable trainer provides vital training experience for students and professionals that will perform operation, safety, and troubleshooting on process control systems used in real-world industrial areas, including power generation, petrochemicals, food processing and manufacturing. To teach real-world skills, the trianing system features industry-standard valves, switches, and gauges all within a portable basic process control learning system that can be placed on a conference room table, shop floor desk, or practically anywhere when training space is limited.

Process control systems, also known as process instrumentation systems, are used in power generation, petrochemicals, manufacturing, and other industries to provide precise control of liquids and gases. Amatrol’s Level and Flow Process Control Troubleshooting Learning System (T5552F) teaches calibration, installation, operation, and troubleshooting of flow and liquid level process control systems and components. The system uses industry-standard components mounted and plumbed in a closed-loop circuit to provide learners with the opportunity to practice manual and automatic control of a process instrumentation system by controlling the water flow rate between two tanks or the liquid level in one tank.

Amatrol’s Level and Flow Process Control Troubleshooting training system uses FaultPro, the industry’s only electronic troubleshooting system, to offer hands-on troubleshooting skills like in-circuit component testing methods and universal digital controller troubleshooting. The system also includes the industry’s best hands-on process control troubleshooting training, covering thirty-six (36) electrical faults, six (6) mechanical faults, PID controller programming errors, flow transmitter programming errors, and I/P converter calibration errors.

Amatrol’s Level and Flow Process Control Troubleshooting Learning System (T5552F) covers calibration, installation, operation, and troubleshooting for flow and liquid level process control systems and components. The process control training system uses industry-standard components mounted and plumbed in a closed-loop circuit to provide learners with the opportunity to practice manual and automatic control of a process instrumentation system by controlling the water flow rate between two tanks or the liquid level in one tank.

Amatrol’s Process Control Troubleshooting Training System uses FaultPro, the industry’s only electronic troubleshooting system, to offer hands-on troubleshooting skills like in-circuit component testing methods and universal digital controller troubleshooting. This process control training system includes the industry’s best hands-on process control troubleshooting training, covering thirty-six (36) electrical faults, six (6) mechanical faults, PID controller programming errors, flow transmitter programming errors, and I/P converter calibration errors.

Process control systems, also known as process instrumentation systems, are used in power generation, petrochemicals, manufacturing, and other industries to provide precise control of liquids and gases.

All products listed were developed in partnership with the FANUC America Education Group and are sold exclusively through the FANUC Education Reseller Network. They carry the industry training curriculum of key manufacturers like FANUC America, Rockwell Automation, and Miller Welding.

Caracol was established to overcome the limits of 3D printing and traditional manufacturing.

Caracol offers extreme additive manufacturing solutions, with no scale limits, for advanced industrial applications.

Amatrol’s Portable PLC Troubleshooting Learning System - Siemens S71200 (990-PS712F) teaches programmable logic controller (PLC) programming, operation, and applications used throughout industry. The system also utilizes FaultPro, the industry’s premier computer-based fault insertion system. FaultPro enables learners to develop key PLC troubleshooting skills, such as PLC input and output testing, software testing, and application troubleshooting.

The portable Siemens PLC troubleshooting training system features real-world components, such as the powerful Siemens S7-1200 PLC and a Siemens Human Machine Interface (HMI) panel. Combined with Amatrol’s in-depth curriculum, learners will gain both theoretical and hands-on knowledge by studying industry-relevant applications and troubleshooting skills that will build a strong foundation for a rewarding career in a variety of industries.

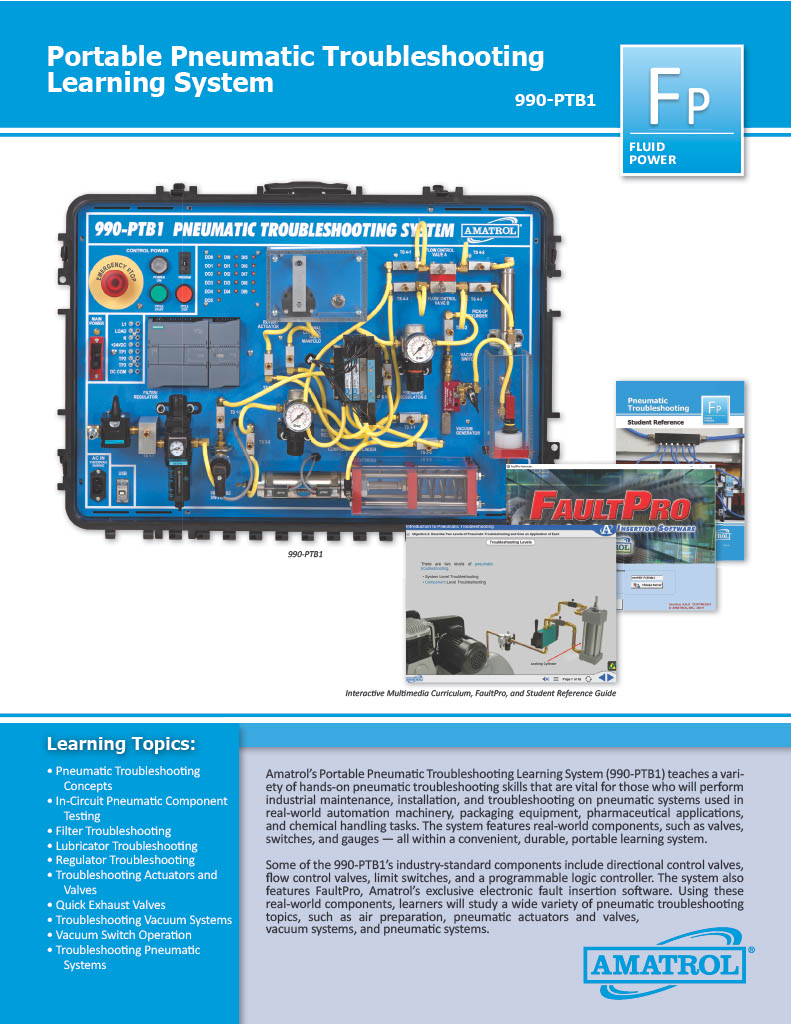

Amatrol’s Portable Pneumatics Troubleshooting Learning System (990-PTB1) teaches a variety of hands-on pneumatic troubleshooting skills that are vital for those who will perform industrial maintenance, installation, and troubleshooting on pneumatic systems used in real-world automation machinery, packaging equipment, pharmaceutical applications, and chemical handling tasks. The system features real-world components, such as valves, switches, and gauges — all within a convenient, durable, portable learning system.

Some of the portable pneumatic troubleshooting training system’s industry-standard components include directional control valves, flow control valves, limit switches, and a programmable logic controller. The system also features FaultPro, Amatrol’s exclusive electronic fault insertion software. Using these real-world components, learners will study a wide variety of pneumatic troubleshooting topics, such as air preparation, pneumatic actuators and valves, vacuum systems, and pneumatic systems.