Explore the world of electric relay control with Amatrol’s Electric Relay Control Learning System (990-EC1A)! This comprehensive training system is designed to teach learners how to interpret, design, and operate relay control circuits using ladder diagrams – essential skills for technicians working with electric motors and fluid power actuators across various sectors.

Equipped with a variety of relay control components and electro-pneumatic elements, this learning system includes an instructor’s guide, installation guide, and student reference guide to facilitate effective learning. The interactive multimedia curriculum offers instruction for hands-on exercises, such as designing continuous-cycle reciprocation circuits with safety interlocks and creating time-driven traffic light circuits.

For added flexibility, consider the portable version (990-EC1F), featuring FaultPro and a digital multimeter to enhance troubleshooting skills. The portable version's multimedia curriculum includes a virtual simulator replicating the hands-on equipment, providing an immersive and portable learning experience. Elevate your understanding of electric relay control – start your learning journey with Amatrol today!

Dive into the future of EMS training with Virtual Reality! VRNA EMS transforms the classroom with fully immersive virtual reality, providing educators with a powerful tool to teach emergency medical treatment. Equip your students with practical skills in a dynamic and engaging virtual environment.

Elevate your EMS curriculum and prepare your learners for real-world scenarios!

Prioritize forklift safety and efficiency with our Forklift Inspection VR Training Course!

What sets our Forklift Inspection VR Course apart?

- Detailed Inspection Training: Immerse yourself in VR scenarios to learn a systematic approach to forklift inspection.

- Safety and Compliance Focus: Understand the significance of regular inspections in alignment with OSHA standards.

- Malfunction Identification Skills: Effectively spot wear, tear, and potential malfunction indicators.

- Record-Keeping Proficiency: Master proper documentation practices for thorough forklift inspections.

- Preventive Maintenance: Gain insights into extending the lifespan and efficiency of forklift equipment.

Who will benefit from this course?

- Forklift Operators and Maintenance Personnel

- Supervisors in Warehouse and Industrial Settings

- Safety Managers and Compliance Officers

- Anyone Involved in Material Handling Equipment Maintenance

Boost forklift operational safety:

- Prevent Major Forklift Malfunctions and Accidents

- Ensure Compliance with Regulatory Standards

- Promote a Culture of Routine Maintenance and Safety

Enrich training, enhance safety, and promote efficiency in forklift operations!

Minds-i Education 2024 Catalog: Unleash the Future of Learning

Dive into the future of education with Minds-i Education's 2024 Product and Curriculum Catalog, designed to elevate classrooms and inspire the next generation of leaders, thinkers, and creators.

What's Inside:

- Immersive In-Classroom Kits: Explore hands-on learning experiences that bring lessons to life, fostering a deeper understanding of concepts and sparking curiosity.

- Electric Car Labs: Unleash the power of electricity and design with our electrifying labs, where students can build, experiment, and learn the fundamentals of electric car technology.

- Mobile Robotics: Immerse students in the world of robotics, providing them with the tools to design, build, and program their own robots, fostering critical thinking and problem-solving skills.

- Drones: Take to the skies with our drone curriculum, allowing students to understand the principles of flight, navigation, and even explore aerial photography.

- Self-Driving Rovers and Tractors: Step into the future with our cutting-edge curriculum on autonomous vehicles, giving students hands-on experience with the technology driving the next generation of transportation.

Why Minds-i Education?

- Innovation in Education: Minds-i is at the forefront of transforming education by providing educators with the tools to inspire and engage students.

- Hands-On Learning: Our products and curriculums are designed to make learning tangible, fostering a love for STEM and preparing students for the challenges of the future.

- Future-Ready Skills: Equip your students with the skills needed to thrive in a rapidly evolving world, from critical thinking to technical expertise.

Join Minds-i Education in shaping the future of learning. Download the 2024 Catalog now and unlock a world of possibilities!

Discover a captivating glimpse into Lucas-Nülle's philosophy and what sets them apart. Their holistic approach fosters a distinctive synergy between hardware and e-learning, culminating in "Real Experience Learning."

Premier Tech, an Authorized System Integrator for FANUC, has engineered and constructed a turn-key sanitary case packing system tailored for the food industry.

System Operation

Within the case packing zone, food items are transported via an infeed conveyor. Here, the FANUC LR-10iA/10 robot adeptly picks up to 30 products per minute. Equipped with an integrated camera for precise distance monitoring and a side shift conveyor reject feature to ensure consistent quality.

Key Advantages

- Swift, precise, and delicate product handling

- Interchangeable gripper facilitates rapid product changeovers

- Capability to manage various product types concurrently

- Constructed from stainless steel to meet rigorous safety requirements

- Intuitive Human-Machine Interface (HMI) for user-friendly operation

FANUC LR-10iA/10 Robot

The FANUC LR-10iA/10 robot, a compact six-axis model, is tailored for diverse picking and handling tasks, notably in warehouse and distribution settings. Its compact design makes it ideal for operations with limited floor space, while its lightweight construction (46 kg) enables versatile mounting options – be it on the floor, upside down, or at an angle. Furthermore, it seamlessly integrates with Automated Guided Vehicles (AGVs) and other mobile platforms to automate idle machines or repetitive tasks effectively.

About Premier Tech

Premier Tech, with a legacy since 1923, is a globally recognized team unified by a shared commitment to drive positive change in people's lives, businesses, and communities. With a workforce spanning 28 countries, our passion and innovative technologies converge to deliver solutions that sustainably nourish, safeguard, and enhance our planet.

As a proud distributor of FANUC's educational products, we're thrilled to showcase a cutting-edge jug load packaging system engineered by FANUC's Authorized System Integrator, Brenton.

System Overview

This innovative setup employs two FANUC M-710 robots to seamlessly handle bottles of various sizes, transferring them from an infeed conveyor into cases. Brenton's screw metering assembly ensures precise bottle orientation, while a servo drive comb assembly efficiently stages them for robot handling. The robots utilize a clamp-style end-of-arm-tool to pick and pack products with precision.

Key Advantages

- Enhanced throughput for increased efficiency

- Versatile handling of bottle sizes ranging from 16oz. to one gallon

- End-of-arm-tool easily accommodates different container sizes

Designed for medium payload applications ranging from 12 to 70 kg, FANUC's M-710 series boasts a slim wrist, rigid arm, and compact footprint. With a reach of up to 3.1 m, these robots offer exceptional performance across a wide array of tasks.

About Brenton

A global leader in end-of-line case packaging systems, Brenton specializes in designing and manufacturing integrated solutions for case packing and palletizing using robotics and automation.

Train with SimSpray®, the automotive industry-leading tool for VR painter training. SimSpray's automotive content pack each include unique parts, paints, and environments designed to meet industry needs.

What is LIFT? One of only a handful of Manufacturing USA Institutes across the country, LIFT is a nonprofit, public-private partnership between industry, academia, and government that supports the nation’s economy and enhances its national security by accelerating innovative advanced manufacturing technology and talent development.

In this video, STEM Talent Program Manager Bernie Simms, Learning Lab Manager Jihad Mims, and Learning Lab/Robotics Instructor Isaac Vanover discuss LIFT’s unique mission to research and develop innovative lightweight materials that advance the nation’s military defense and manufacturing capabilities.

According to Mims, “We also realized that there’s a very large skills gap. Over 2.5 million jobs within manufacturing were going unfilled, so to bridge that gap, we also wanted to make sure that education and workforce development was implemented in LIFT’s atmosphere. ”

That’s why you’ll find a wide variety of Amatrol training systems and eLearning curriculum in the LIFT Learning Lab. Amatrol also partnered with LIFT to develop the IGNITE: Mastering Manufacturing high school career and technical education program.

A fully automated cartoner for pouches, featuring robotic collation and loading, was engineered by FANUC’s Authorized System Integrator.

System Operation

Pouches emerge from the customer's pouch form-fill-seal (FFS) machine in a single-file fashion. The M-1iA robot strategically arranges alternate pouches, forming dual lanes at the cartoner infeed. Subsequently, two M-2iA robots precisely stage the pouches within collation fixtures, while an SR-6iA erects auto-bottom cartons and positions them on the carton conveyor. An M-10iD/12 robot expertly picks the staged pouches and deposits them into the erected cartons. The carton's top is then folded and tucked, and a collaborative CRX-10iA robot efficiently removes closed cartons, transferring them onto racks.

Key Advantages

- Capable of handling 100 pouches per minute

- Enhanced packaging speed

- Reduced footprint

ESS Technologies, Inc., a Pacteon Company, is a leading expert in comprehensive packaging line solutions, catering to industries such as pharmaceuticals, nutraceuticals, cosmetics, and consumer packaged goods. With a foundation dating back to 1993, ESS possesses extensive proficiency in designing, manufacturing, and integrating automatic cartoners, case packers, robotic palletizers, and TaskMate Robotic Systems®.

Pages

-

Every individual should be trained with hands-on skills for basic workplace safety. With our Enterprise Safety package, you get seven modules that allow learners to put safety training into practice in a safe, virtual environment. The training modules include Confined Space, LOTO, Fall Protection, AED, CPR, Fire Suppression, and Virus Vision.

-

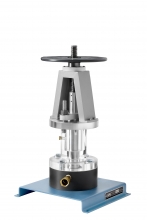

Item Number:250-000DAC Worldwide’s Valve Packing Training System (250-000) is a detailed replica of a six-inch gate valve, equipped with a backseat, which facilitates the proper removal and installation of packing.

-

Item Number:250-PACIndustrial maintenance technicians must be familiar with a wide variety of valves used throughout many different types of industries. A common task technicians encounter on the job is replacing valve packing to prevent valves from leaking.

-

Item Number:272-718DAC Worldwide's Dissectible Variable Area Flow Meter (272-718) (rotameter) allows for close visual inspection of a common PVC and acrylic liquid flow meter to better understand its function, design characteristics, operation, and possible maintenance.

-

Item Number:205-290DAC Worldwide's Variable Speed Gear Reducer Cutaway is a sectioned variable speed industrial gear reducer. Speed variations allow for continuous variable-ratio speed adjustment of mechanical systems are still regularly encountered in industrial applications due to their durability, dependability, and consistency of operation.

-

Item Number:275-128DDAC Worldwide’s Vertical Centrifugal Pump Dissectible (275-128D) is an actual industrial centrifugal pump assembly that allows for realistic training in the field or bench-top disassembly, inspection, and reassembly of a vertical centrifugal pump.

-

Item Number:207-000DAC Worldwide’s Vertical Coupling/Shaft Alignment Training System (207-000) is a heavy-duty, precision learning system that allows for convenient, realistic training in shaft alignment. When paired with a variety of hands-on exercises, the system creates a complete performance-based course in the maintenance of shaft alignment.

-

Item Number:207-PACDAC Worldwide’s Vertical Coupling/Shaft Alignment Training System Plus (207-PAC) is a heavy-duty, precision learning package that allows for convenient, realistic training in shaft alignment. When paired with a variety of hands-on exercises, the training system creates a complete performance-based course in the maintenance of shaft alignment.

-

Item Number:295-115DAC Worldwide's Vertical Cross-Flow Separator Model (209) is a highly-detailed scale model of a common vertical cross-flow separator used throughout the oil and gas industry, as well as other processing, production, and refining applications.

-

Item Number:295-101DAC Worldwide’s Vertical Separator Trainer (295-101) is a reduced-scale, three-phase vertical separator that mimics its real-world counterpart by using alternate production stream components, refined oil, air, and water.