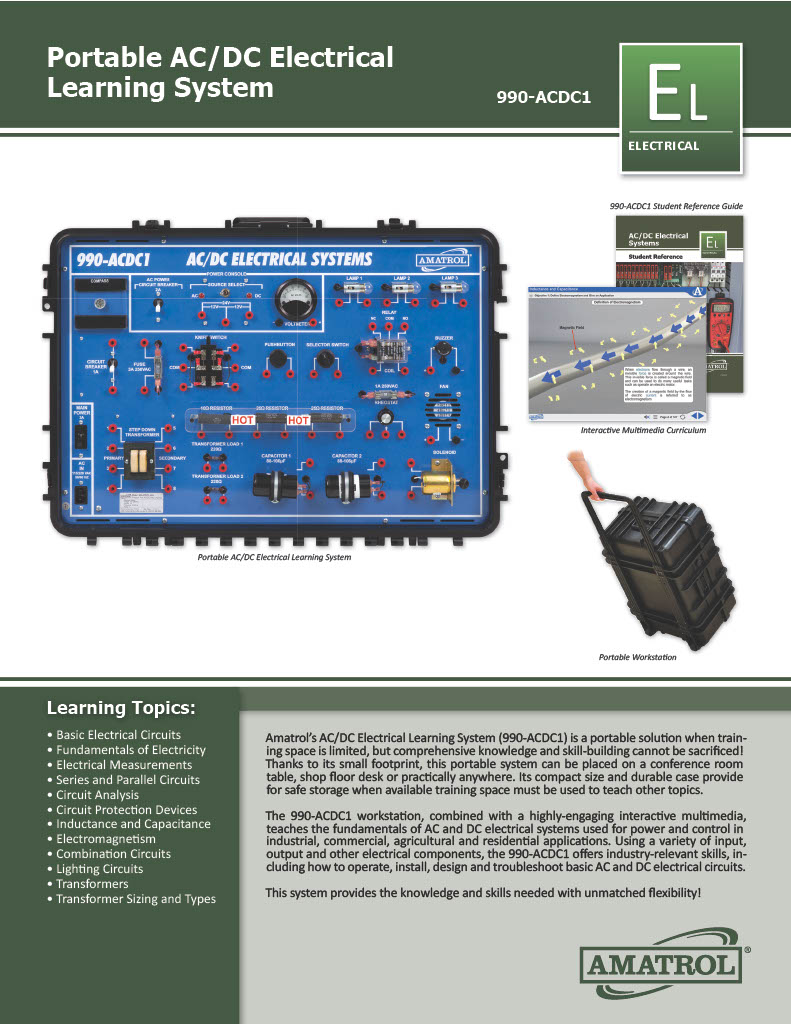

Amatrol’s Portable AC/DC Electrical Learning System (990-ACDC1) teaches the fundamentals of AC and DC electrical systems used for power and control in industrial, commercial, agricultural, and residential applications. The 990-ACDC1 offers industry-relevant skills including how to operate, install, design, and troubleshoot basic AC and DC electrical circuits for various applications.

This portable AC/DC electrical learning system brings customers flexibility and convenience when there’s a need to use a trainer in multiple locations or where space is too small for a full-size trainer. Set within a durable ABS plastic case, the 990-ACDC1 features wheels and a handle to create a completely mobile learning system. This highly efficient learning system also includes a lock for safety and a storage pouch in the inside cover for loose components, such as banana leads. The system’s front cover is easily removed, enabling the case to sit upright on a flat surface.

The 990-ACDC1 includes a variety of switches and other components so learners can build different circuits, which will help them to recognize industrial component styles and learn how to troubleshoot them effectively. Combined with Amatrol’s world-class curriculum, this innovative product can provide learners with a thorough understanding of electrical power.

Amatrol's Portable Electric Training System (990-ACDC1) is a great way to train electric concepts. Partnered with interactive multimedia, this learning system is a good cornerstone to any program.

Amatrol’s Portable Basic Hydraulics Training System (990-BH1) allows learners to gain skills by studying topics like basic hydraulic circuits, pressure control circuits, hydraulic schematics, and sequence valves. Also, given the compact nature of the Portable Basic Hydraulics system, for the first time you can teach hydraulics in a limited space. This learning system allows learners to study and practice how to read a pressure gauge, as well as liquid level and temperature in the reservoir, connecting hydraulic circuits, operating a bi-directional hydraulic motor, converting between absolute and gauge pressure, and connecting and adjusting the pressure setting of a pressure relief valve (PRV).

The mobile Basic Hydraulics training includes gauges, manifolds, cylinders, valves (relief/sequence, pressure reducing, check, directional control, etc.), flow meter, and hydraulic motor. The components of this portable trainer are all industrial quality, not only to ensure durability, but also to help learners become better prepared for what they will encounter on the job. All Amatrol products are made from top-notch materials and carefully crafted to create tough, attractive, well designed learning systems that facilitate learning and will serve teachers and learners for years. Amatrol uses components that learners will find on-the-job in order to give the best opportunity to build confidence and industrial competencies.

Amatrol’s Portable AC Variable Frequency Drives Troubleshooting Learning System (990-DRV1F) teaches the fundamentals of configuring and operating an AC variable frequency drive. The AC motor drive troubleshooting system includes industry-standard components, such as an Allen-Bradley PowerFlex 4 variable frequency AC drive and a 3-phase AC motor, in a convenient, portable case that can be used virtually anywhere.

The system also features FaultPro, Amatrol’s exclusive electronic fault insertion software. FaultPro allows users to learn motor drive troubleshooting skills, such as drive input, motor input, and drive relay troubleshooting. FaultPro allows users to troubleshoot realistic situations they will encounter on the job in industries like packaging, textiles, and paper where rapid motor acceleration and deceleration are required.

Amatrol’s Portable Electric Relay Control Troubleshooting Training System (990-EC1F) covers concepts widely used in industrial, commercial, and residential applications to regulate electric motors and fluid power actuators, as well methods used for troubleshooting problems in relay control components and systems. This portable learning system offers learners flexibility and convenience when there’s a need to use a trainer in multiple locations or where space is too small for a full-size trainer.

The 990-EC1F includes a relay control panel with pre-mounted electrical control, pneumatic, and electric power components. Learners can use these components to connect electrical terminals to heavy-duty banana jacks to test various automation control circuits. This system also includes a digital multi-meter that will be used for troubleshooting concepts and skills. Combined with Amatrol’s world-class interactive multimedia curriculum, this innovated product can provide learners with a thorough understanding of electric relay control.

Amatrol’s Portable Power and Control Electronics Learning System (990-ELE1) teaches learners how to operate, adjust, and troubleshoot electronic components, circuits, and systems used in machine applications. This powerful training system allows users to explore the fundamental concepts of industrial power and control electronics, such as measuring temperature, speed, and analog signals, in a convenient, compact unit that can be easily transported for use in multiple locations.

The 990-ELE1 features a wide variety of industry-standard electrical components and circuits that can be set up in a wide variety of real-world machine applications. These components will help learners gain hands-on experience with linear power supplies, solid state relays, discrete and thermal sensing devices, solid state switching, and more! The 990-ELE1 also utilizes FaultPro, the industry’s premier computer-based fault insertion system that enables learners to develop key industry troubleshooting skills. FaultPro features 30 different faults to present learners with realistic troubleshooting experiences.

Amatrol’s Portable Electric Motor Control Troubleshooting Learning System (990-MC1FSL) features standard industry components like a 3-phase AC squirrel cage motor and uses 3-phase AC for power and 24 VDC for control all packed within a space-saving, portable product. These real-world motor control components will prepare learners for work opportunities in industries where electric relay control is used in applications like conveyor control and driving large utility pumps. Teach students how to read and interpret ladder diagrams. The 990-MC1FSL also uses FaultPro, Amatrol’s unique electronic fault insertion, to teach motor control troubleshooting skills, such as control relay, reversing contactor, limit switch, and pushbutton troubleshooting.

The 990-MC1FSL uses industrial components to cover the operation, installation, and applications for electric relay control of AC motors all within this portable, durable learning system that can be set up nearly anywhere. This system also builds knowledge and skills across topics like manual motor control, control ladder logic, motor starters, and automatic input devices. Nowhere else can you find this breadth of training in a portable platform!

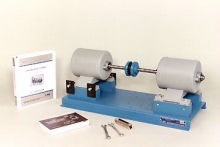

Amatrol’s Portable Mechanical Drives 1 Learning System (990-ME1M) covers the fundamentals of mechanical transmission systems and applications, such as how to: operate, install, analyze performance, and design basic mechanical transmission systems using chains, vbelts, spur gears, bearings, and couplings. These mechanical system fundamentals can be applied to a variety of applications within the automotive, agricultural, and power industries.

The 990-ME1M includes: a tabletop mounting work surface; a drive motor; a variety of components for belt, chain and gear drives; a digital tachometer; a mechanical load device; and an alignment package. This power transmission training system uses industrial quality components to help assure that learners are better prepared for what they will encounter on the job and to withstand frequent use. These components will be used to cover major mechanical drives topics like shaft speed measurement, key fasteners, power transmission systems, belt drive concepts, chain tensioning, and gear backlash. The 990-ME1M features the ability to set up various drive systems, showing learners the effects of proper alignment and how to obtain best efficiency.

Amatrol’s Portable Fundamental Measurement Tools Learning System (990-MES1) introduces the fundamental principles of measurement including basic measurement, precision measurement, direct gauging, indirect gauging, and dimensional measurements using both the U.S. customary system as well as S.I. metric system. Understanding how to perform accurate measurements is relevant to technical careers such as quality control inspector, machinist, manufacturing engineer, operations manager, and production technician. The measurement training system’s compact size and durable case also provide for safe storage when available training space must be used to teach other topics.

The 990-MES1 allows learners to apply fundamental measurement principles using industry-standard tools like dial calipers, micrometers, and dial indicators to achieve accurate measurements that are essential to any technical career. Learners will acquire skills such as how to measure length, accurate measurement of inside and outside dimensions, measuring both in U.S. Customary and S.I. Metric units, and collecting measurement data. The 990-MES1 contains precisely-machined and numbered parts that challenge the learner to make accurate measurements. The measurement tools and parts were carefully selected to not only teach the learner how to use the tools properly, but to also teach them the proper application for their use.

Amatrol’s Portable PLC Troubleshooting Learning System - AB CompactLogix L16 (990-PAB53AF) teaches programmable logic controller (PLC) programming, operation, and applications used throughout industry. The system also utilizes FaultPro, the industry’s premier computer-based fault insertion system. FaultPro enables learners to develop key PLC troubleshooting skills, such as PLC input and output testing, software testing, and application troubleshooting.

This portable system provides hands-on experience with real-world components, including the powerful Allen-Bradley L16 CompactLogix 5300 PLC, a PanelView Plus terminal, an Ethernet Switch, an I/O Simulator, five application circuits, and a master control relay circuit. Learners will study industry-relevant applications and troubleshooting skills that will build a strong foundation for a successful career in a variety of industries.

Pages

-

Let your students build employable skills by working on state-of-the-art real-world systems that teach the procedures required to work safely on today’s vehicles.

-

Item Number:MCK-MRLB-001Explore new frontiers in STEM education with the MINDS-i STEM Integrated Robotics: an Autonomous Self-Driving Mars Rover. This rover, equipped with cutting-edge GPS and IMU technology, elevates STEM learning by immersing students in programming, electromechanical systems, and autonomous navigation.

-

To engage and reach learners with a variety of learning styles, Amatrol’s Aviation Maintenance Training program features a robust combination of learning methods to provide an outstanding learning experience that includes both comprehensive theoretical knowledge and practical, hands-on skills valuable throughout industry.

-

Item Number:211ADAC’s Axial Compressor Model (211A) depicts a highly detailed scale model depicting features of industrial axial air compressors commonly used in oil and gas production.

-

Release B1, protection grade IP68, focus on industrial landing, industrial super-large payload, dust-proof and waterproof.

-

Item Number:BHLSimlog’s Backhoe Loader Personal Simulator puts trainees at the controls of a backhoe loader (BHL) at work in a typical construction site. Special configuration parameters enable instructors to modify the 3D modeling, allowing them to select one of five possible color combinations and set the number of lift arm cylinders to either one or two.

-

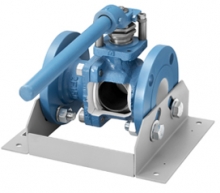

Item Number:253DAC Worldwide’s Ball Valve Cutaway (253) takes classroom training in the operation, construction, and maintenance of an industrial ball valve and enhances it by providing a visual, hands-on learning aid. The fully-detailed examples of industrial downsized valves give learners a first-hand view inside a component that is found in various maintenance applications worldwide.

-

Item Number:295-711DAC Worldwide’s Barrel Choke Valve Cutaway (295-711) is an industrial valve sample for training in the operation, construction, and maintenance of a fixed (bean-type) choke valve.

-

Item Number:208D-000Tech-Labs technical training solutions.

-

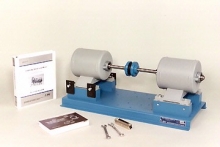

Item Number:208D-PACDAC Worldwide’s Basic Coupling/Shaft Alignment Training System Plus (208D-PAC) is a heavy-duty, precision learning package that allows for convenient, realistic training in shaft alignment.