In this video, Cam Wyatt and Triniti Gutierrez share how X-Cal's support transformed an idea into a reality. From providing the latest training equipment to offering technical expertise, X-Cal played a key role in helping EPIC bring hands-on education to life. This trailer allows students to explore real-world trade opportunities, filling critical employment gaps in the construction industry.

X-Cal we specializes in helping institutions like EPIC achieve their mission by equipping them with the tools and knowledge needed to succeed. Whether it's mobile learning labs or state-of-the-art training solutions, X-Cal is committed to empowering the next generation of skilled workers. Let us help your organization do the same.

Discover how College of the Mainland’s Industrial Careers Program, led by Program Manager Kermit Harris, is preparing students for success in refinery instrumentation and electrical careers. Using state-of-the-art training equipment and curriculum provided by Tech-Labs, students gain the knowledge and hands-on experience needed to confidently enter the workforce.

This program goes beyond education—it transforms lives. Hear the heartfelt story of how one student’s journey from uncertainty to a promising career showcases the power of technical training.

Key highlights include:

- Real-world training on advanced industrial trainers.

- Expert guidance that builds a solid foundation for refinery work.

- Stories of life-changing impact and career growth.

Join the movement. Learn how Tech-Labs can empower your training programs today!

Oklahoma State University-Oklahoma City (OSU-OKC) is setting a new benchmark for advanced manufacturing education through its innovative FAME program. With a vision to create industry-ready professionals, the program combines academic rigor, hands-on training, and real-world industry experience.

What is the FAME Program?

The Federation for Advanced Manufacturing Education (FAME) provides a world-class workforce development model that combines strong technical training, manufacturing core competencies, and intensive professional practices. Through intentional hands-on experience, FAME prepares students to excel in the modern manufacturing industry and meet the evolving demands of employers.

Originally created by Toyota, FAME transitioned to the Manufacturing Institute in 2019 for national scaling. As the workforce development and education partner of the National Association of Manufacturers, the Manufacturing Institute now manages FAME USA, which continues to grow with the support of over 450 manufacturers nationwide.

At OSU-OKC, the FAME program integrates this proven model, offering students a unique opportunity to work in industry while attending school. This approach ensures graduates are equipped with the skills, experience, and professional mindset to thrive in advanced manufacturing careers.

By leveraging industry partnerships and cutting-edge equipment provided by Tech-Labs, OSU-OKC’s FAME program is shaping the future of manufacturing education and talent development in Oklahoma and beyond..

Industry Partnerships for Success

The program requires students to work in industry while completing their coursework. This mutual commitment ensures students receive both theoretical and practical knowledge, creating a workforce that’s ready to contribute from day one.

Tech-Labs: Empowering Education

Tech-Labs has played a crucial role in OSU-OKC's success. By providing state-of-the-art equipment and ongoing support, Tech-Labs has helped establish an environment where students can learn using tools that mirror what they will encounter in industry. From setup and training to sustained service, Tech-Labs has been a vital partner in OSU-OKC’s journey to excellence.

Impactful Outcomes

The FAME program is already making a difference in the lives of students like Tyler Connor, who values the hands-on experience and the opportunity to make an impact in the field. The program is not just about teaching skills but also about instilling servant leadership and creating a legacy of innovation.

Contact us to learn more about our advanced training solutions!

Empowering the Next Generation of Semiconductor Professionals

Train the Next Generation of Semiconductor Manufacturing Professionals

The semiconductor industry is booming thanks to the CHIPS Act, driving unprecedented investments in manufacturing and innovation. With this growth comes the urgent need for a highly skilled workforce. Amatrol is here to help you design custom training programs that equip students with the hands-on skills required to succeed in this dynamic field.

Comprehensive Training for Advanced Manufacturing & Industry 4.0 Careers

IGNITE, Amatrol’s comprehensive skill development program, is tailored for high schools and colleges. Available in 1-, 2-, or 3-year formats, IGNITE stimulates interest in advanced manufacturing careers while teaching industry-aligned skills. These courses prepare students for Smart Automation Certification Alliance (SACA) credentials, including the industry's first semiconductor-specific certifications developed with the Florida Semiconductor Institute.

Cutting-Edge Curriculum and Technology

Amatrol’s eLearning programs are designed to engage learners of all styles with:

- Interactive Multimedia: Stunning 3D graphics, voiceovers, and videos.

- Quizzes & Exercises: Reinforce understanding and practical application.

Our hands-on trainers provide unparalleled opportunities for students to practice skills critical to semiconductor manufacturing.

Key Training Modules

Amatrol offers training solutions for a wide range of topics in advanced manufacturing and semiconductor technology, including:

Smart Manufacturing

- Tabletop Smart Factory

- Smart Process Sensors

- Virtual Trainer for Smart Machine Sensors

Electrical & Electronics

- AC Motor Drives

- PLC Troubleshooting

Lean Manufacturing

- 5S Methodology

- Kaizen & Value Stream Mapping

- Total Productive Maintenance

- Basic Pneumatics

- Pneumatics Troubleshooting

Pneumatics

Safety Practices

- Lockout/Tagout

- Hazardous Communication

- Confined Spaces

Measurement Tools

- Precision Gauging

- Multiview & Assembly Drawings

- Inspection Techniques

Why Choose Amatrol?

- ISO 9001:2015 Certified Quality: Trusted for delivering exceptional training solutions.

- Hands-On Learning: Comprehensive trainers that simulate real-world scenarios.

- Industry-Aligned Credentials: Courses aligned with certifications from SACA and other recognized organizations.

Empowering the Semiconductor Workforce of Tomorrow

The Semiconductor Boom: A Golden Opportunity for Training Programs

The CHIPS Act has ignited massive growth in semiconductor manufacturing, creating an urgent demand for a highly skilled workforce.

- 80+ new projects across the U.S.

- $447 billion in private investments in 25 states

- Over 56,000 high-quality jobs available

States like Texas, Oklahoma, New Mexico, Utah, Colorado, Wyoming, Montana, and Idaho are experiencing unprecedented demand for skilled workers in this rapidly expanding sector. Now is the time to prepare students and workers to meet the needs of this high-tech industry.

Why Amatrol?

Amatrol’s comprehensive training solutions align with industry-recognized credentials from the Smart Automation Certification Alliance (SACA), developed in partnership with the Florida Semiconductor Institute. These credentials certify essential hands-on skills needed for the semiconductor manufacturing workforce.

Features of Amatrol Training Programs:

- Interactive eLearning Curriculum: Engaging 3D graphics, videos, voiceovers, and quizzes appeal to all learning styles.

- Cutting-Edge Topics:

- Smart Manufacturing

- Basic Pneumatics

- PLC Troubleshooting

- Smart Process Sensors

- Pneumatics Troubleshooting

- Virtual Trainers

- AC Motor Drives

- Blueprint Reading

- Safety Practices & Regulations

Tailored Solutions for Industry and Universities

Amatrol helps universities and industrial training programs design custom training programs to prepare the next generation of semiconductor workers. Equip your students with:

- Smart Factory Systems

- Electrical and Electronics Training

- Precision Gauging Techniques

- Lean Manufacturing Practices

Addressing Workforce Needs in Key States

Semiconductor manufacturers in Texas, Oklahoma, New Mexico, Utah, Colorado, Wyoming, Montana, and Idaho are facing a growing skills gap. By integrating Amatrol’s advanced training systems, your program can:

- Provide industry-standard credentials.

- Develop hands-on competencies for high-tech careers.

- Address the regional demand for skilled technicians in this booming field.

The TDL Academy at Western Guilford High School provides students with a transformative journey from classroom learning to high-demand careers in transportation, distribution, and logistics. Established in the 2019–2020 school year, this innovative program equips students with the skills, knowledge, and experience to excel in a rapidly growing industry.

Hands-On, Simulator-Based Training

- Students engage in real-world projects and problem-solving scenarios.

- Simlog simulators provide immersive training experiences, including forklift and reach truck operations.

- From beginner to advanced levels, students master equipment controls and full operation, preparing them to step into real-world roles confidently.

Building Career Pathways Through Partnerships

TDL Academy’s partnerships with leading companies like Fastenal and FedEx offer students real-world internship opportunities. These collaborations bridge classroom learning with workplace readiness, ensuring students leave the program career-ready. Many graduates transition into full-time roles, thriving in logistics careers while pursuing further education.

Simlog Simulators: The Key to Success

- Simlog forklift and reach truck simulators provide industry-standard training tools.

- Students gain hands-on experience in operating both stand-up and sit-down equipment.

- Simlog simulators support a range of users, from beginners to experienced technicians seeking supplemental training.

Success Stories

- Graduates have excelled in positions at logistics giants like Fastenal and FedEx Freight.

- Interns gain a competitive edge with Simlog-based simulator training, making them highly valued in the workforce.

- Companies report reduced training times and increased productivity thanks to the hands-on experience students receive.

Empowering Students for High-Demand Careers

With the capacity to train 60 students annually, the TDL Academy delivers a win-win solution for students, schools, and businesses. Graduates are job-ready and equipped to thrive in a field where skilled professionals are in high demand.

Take the Next Step

Ready to elevate your logistics training program? Discover how Simlog simulators can transform your classroom into a hands-on, career-ready learning environment. Whether you're starting a new program or enhancing an existing one, Simlog’s cutting-edge forklift and reach truck simulators provide the tools to prepare students for high-demand jobs in transportation, distribution, and logistics.

Contact us today to learn how to integrate Simlog simulators into your curriculum and create a pipeline of skilled, job-ready graduates!

Discover the industry-leading Smart Process Plant Training System (Model 603-SP)—a hands-on solution for mastering the complexities of process control systems. Designed for real-world training, this system allows learners to measure and control critical process variables, including level, pressure, temperature, flow, and pH. Featuring industry-standard components and advanced technologies, the 603-SP prepares trainees for careers in power generation, petrochemicals, biotechnology, food processing, and beyond.

Download the brochure to explore how the 603-SP integrates cutting-edge tools like smart sensors, distributed control systems (DCS), and Rockwell Automation’s PlantPAx software to provide a robust, immersive learning experience. Learn about hands-on exercises and experiments that simulate real-world applications, such as bioreactor operations, clean-in-place (CIP) systems, and wastewater treatment. Equip your team with the skills they need to excel—download now!

Discover the Power of Stratasys 3D Printers for Education

Empower your students to innovate and create with Stratasys 3D printers, the trusted choice for educators worldwide. Whether enhancing STEM curricula, equipping Makerspaces, or supporting design and engineering programs, Stratasys delivers reliable, industry-leading additive manufacturing technology tailored to educational environments.

Learn how schools, colleges, and universities can integrate these solutions to inspire hands-on learning and future-ready skills in students. With robust technical support and curriculum resources, Stratasys simplifies the adoption of 3D printing into your classroom or lab.

Why Stratasys Stands Out for Education

With a focus on innovation, sustainability, and accessibility, Stratasys offers a range of 3D printers designed for diverse educational applications. Explore how your institution can leverage Stratasys technology to foster creativity, collaboration, and real-world problem-solving. Dive into the brochure to uncover exciting features, case studies, and exclusive promotions available for educators like you.

Download the brochure now and take the first step toward transforming your educational programs with Stratasys!

Hands-On CNC Plasma Cutting Experience for Students in 30 Minutes or Less

Lincoln Electric® CNC plasma cutting tables are the ideal addition to educational programs, providing students with real-world skills in precision metal cutting. Designed as fully integrated systems, these machines offer seamless operation, allowing instructors and students to focus on learning rather than troubleshooting equipment.

Why Choose Lincoln Electric® for Your Classroom or Training Lab?

- Turnkey Solutions for Educators: Fully assembled and ready to use—start teaching metal cutting skills the same day the table arrives.

- Integrated Design: Every component is engineered to work together, ensuring reliable performance and easy operation for students.

- Durable and Low Maintenance: Torchmate tables are built to handle the rigors of daily classroom use with minimal upkeep, so your focus remains on teaching.

- Industry-Standard Training: Equip students with hands-on experience using technology trusted by professionals in manufacturing and fabrication.

Whether you’re running a high school CTE program, a technical college course, or a workforce development initiative, Lincoln Electric® CNC plasma tables empower students with practical, job-ready skills in CNC programming and metal fabrication.

Empowering Workforce Development with Lincoln Electric® Torchmate

Waukesha County Technical College (WCTC) is a leader in workforce development, offering over 150 programs, including associate degrees, technical diplomas, apprenticeships, and short-term certificates. With Waukesha and Pewaukee, Wisconsin campuses, WCTC delivers hands-on training designed for immediate application in the workplace. As a proud partner of Lincoln Electric®, WCTC equips its students with cutting-edge tools and skills to meet industry demands.

Upgrading to the Torchmate 5100 for Better Learning Outcomes

In the Fall semester of 2022, WCTC upgraded its CNC plasma-cutting capabilities by investing in a Torchmate 5100 equipped with a FineLine® 170HD. This advanced system replaced their previous 2’x4’ Torchmate Growth Series tables. It enabled students to work on larger sheets and produce higher-quality cuts, even on thicker materials like half-inch aluminum and steel.

- Enhanced Precision: Achieves superior cut quality on a wide range of materials.

- Increased Capacity: Handles extended work hours, with students using the table for 20+ hours each week.

- Diverse Applications: Students create parts for welding classes, fire pits, metal décor, smoker grills, and more.

Real-World Training Leads to Career Success

WCTC’s Automated Cutting Processes program, part of the Automated Systems Technology curriculum, integrates CNC plasma cutting with robotics and programmable logic controllers (PLCs). Students gain hands-on experience operating advanced systems like the Torchmate 5100, learning automation principles critical in modern industries.

Success Stories

Graduates of the Automated Systems program have secured roles at industry leaders like Messer, a global provider of industrial and medical gases:

- Three alumni now serve as application engineers.

- One graduate works as a product manager.

- Another alum is a software engineer.

These career placements highlight how WCTC’s partnership with Lincoln Electric® empowers students to achieve high-level roles in their fields.

Lincoln Electric®: Partnering with Educators

Lincoln Electric® is committed to supporting education by providing instructors with state-of-the-art equipment and comprehensive training. WCTC’s arsenal of Lincoln Electric products includes:

- Torchmate 5100 with FineLine® 170HD

- Tomahawk® manual plasma cutters

- Robot welding machines

- Power Wave®, Flextec®, and Precision TIG® welders

After the Torchmate 5100 purchase, Lincoln Electric sent expert trainers to WCTC, ensuring educators were equipped to maximize the machine’s capabilities.

“Lincoln Electric is a trusted name with a long history. They have individually focused teams that perfect each product. They’ve done great for WCTC, and I would absolutely recommend the Torchmate 5100.” – Brad LeTourneau, WCTC Metal Fabrication and Welding Instructor

Investing in the Future Workforce

By partnering with schools like WCTC, Lincoln Electric® ensures the next generation of welders, engineers, and fabricators is well-prepared for industry challenges. With innovative solutions like the Torchmate 5100, students gain the skills and confidence to succeed in their careers.

Ready to bring Lincoln Electric® solutions to your school? Contact us today to learn more about how our training systems can empower your students.

Pages

-

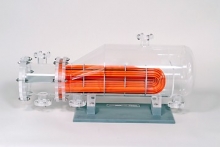

Item Number:288DAC Worldwide’s Kettle Type Reboiler Heat Exchanger Training Model (288) depicts a highly-detailed scale model of a kettle-type reboiler in a technically-accurate, professionally-crafted design that supports training in the operation and maintenance of industrial heat exchangers.

-

Item Number:209DAC Worldwide's Kingsbury Thrust Bearing Model (209) is a plastic facsimile of a Kingsbury fluid film thrust bearing that allows for classroom instruction in the design, maintenance, and application of fluid film bearings used in industry.

-

Teaching the basics of ladder health and safety can help prevent potential injuries and inform others on how to identify if a ladder is a potential risk. The Ladder Safety simulation is ideal for future employees or supervisors who will work in or around work environments that utilize ladders.

-

Item Number:295-696DAC Worldwide’s LACT Component Cutaway and Demonstration Package (295-696) is a full-size, realistic mock-up of a generic LACT unit that has been purposefully modified for classroom training through the inclusion of multiple system component cutaways.

-

Item Number:T5552FAmatrol’s Level and Flow Process Control Troubleshooting Learning System (T5552F) covers calibration, installation, operation, and troubleshooting for flow and liquid level process control systems.

-

Item Number:295-705DAC's Lever-Operated Dump Valve Cutaway (295-705) is a valve sample for training in the operation, construction, and maintenance of an industrial lever-operated oil dump valve.

-

Item Number:LMH-300Experience the future of CNC machining with the LMH-300 5X—a precision 5-axis milling machine designed for advanced part production, educational training, and robotic automation. Perfect for schools and industry.

-

Item Number:LMT-300Prepare students for the future of advanced manufacturing with the LMT-300 “Mystique” 5-Axis Mill-Turn. Compact, powerful, and classroom-ready, this machine brings real-world CNC training to your lab.

-

Item Number:LMV-400 CNCCompact, powerful, and automation-ready — Levil Technology's LMV-400 CNC milling machine combines precision machining with FANUC robotic integration for education and industry.

-

Item Number:LTC-30The LTC-30 is a robust system designed for the industrial production of small parts. You will not find another lathe at this size that will give you the same rigidity and precision while cutting a wide variety of materials.