Amatrol’s Portable PLC Troubleshooting Learning System - Siemens S71200 (990-PS712F) teaches programmable logic controller (PLC) programming, operation, and applications used throughout industry. The system also utilizes FaultPro, the industry’s premier computer-based fault insertion system. FaultPro enables learners to develop key PLC troubleshooting skills, such as PLC input and output testing, software testing, and application troubleshooting.

The portable Siemens PLC troubleshooting training system features real-world components, such as the powerful Siemens S7-1200 PLC and a Siemens Human Machine Interface (HMI) panel. Combined with Amatrol’s in-depth curriculum, learners will gain both theoretical and hands-on knowledge by studying industry-relevant applications and troubleshooting skills that will build a strong foundation for a rewarding career in a variety of industries.

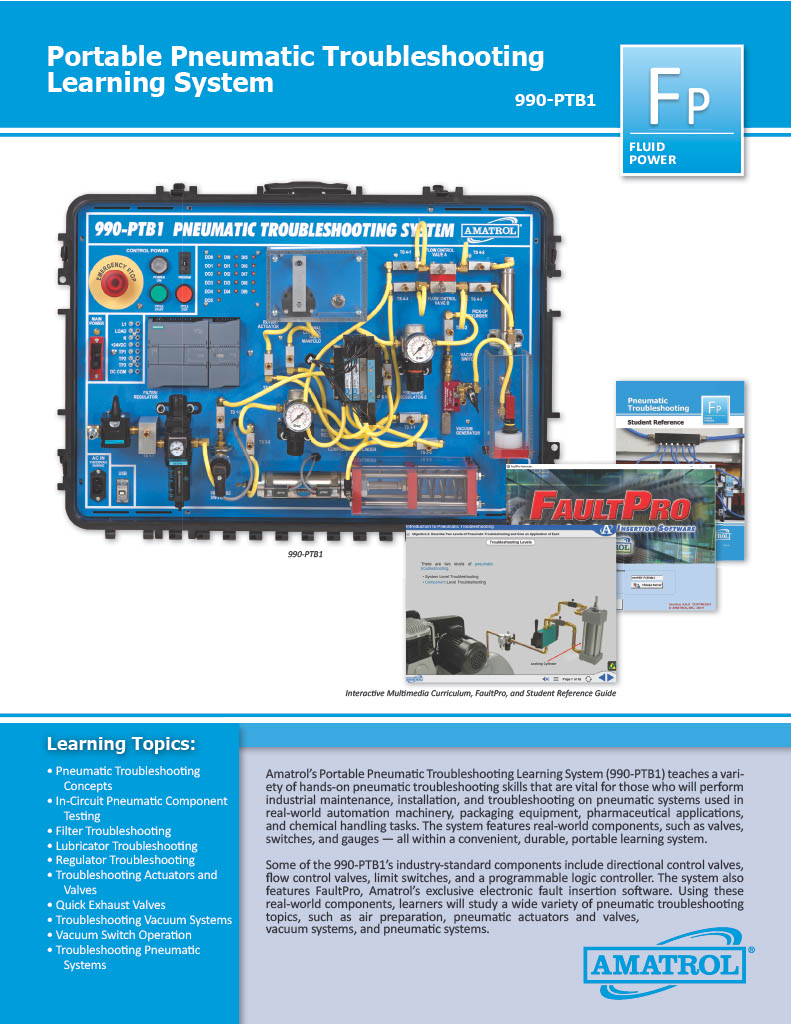

Amatrol’s Portable Pneumatics Troubleshooting Learning System (990-PTB1) teaches a variety of hands-on pneumatic troubleshooting skills that are vital for those who will perform industrial maintenance, installation, and troubleshooting on pneumatic systems used in real-world automation machinery, packaging equipment, pharmaceutical applications, and chemical handling tasks. The system features real-world components, such as valves, switches, and gauges — all within a convenient, durable, portable learning system.

Some of the portable pneumatic troubleshooting training system’s industry-standard components include directional control valves, flow control valves, limit switches, and a programmable logic controller. The system also features FaultPro, Amatrol’s exclusive electronic fault insertion software. Using these real-world components, learners will study a wide variety of pneumatic troubleshooting topics, such as air preparation, pneumatic actuators and valves, vacuum systems, and pneumatic systems.

Amatrol’s Portable Smart Machine Sensor Learning System (990-SD10) is an innovative, compact training solution designed to equip learners with cutting-edge Industry 4.0 skills. Featuring real-world components and advanced eLearning, this portable system allows users to practice configuring and testing smart sensors, exploring IIoT environments, and mastering cloud computing applications—all in a durable, mobile training kit.

The Portable Smart Machine Sensor Learning System covers topics like an introduction to IIoT, cloud computing, photoelectric sensor configuration, smart sensor configuration and monitoring, smart condition monitoring sensors, and smart RFID readers. Within these topics, learners will study about data analytics, IO-Link Master function and operation, configuring a variety of smart sensors, as well as practice skills like monitoring and testing the output of a smart power supply, configuring and testing smart sensors using an IO-Link Bluetooth application, and operating an RFID system.

Comprehensive Learning Topics

Gain hands-on experience with concepts and tools critical to Industry 4.0:

- Industrial Internet of Things (IIoT)

- Cloud Computing

- Photoelectric Sensor Configuration

- Smart Condition Monitoring Sensors

- IO-Link Master Function

- Smart RFID Readers and Components

This training system allows learners to build essential skills for careers in Smart Factory environments, including:

- Operating RFID systems

- Configuring and testing smart sensors (e.g., ultrasonic, photoelectric, vibration, and linear position sensors)

- Monitoring outputs using IO-Link software and Bluetooth applications

With real-world components like smart power supplies, IO-Link Masters, and multi-function smart sensors, students are prepared to tackle challenges in the growing field of industrial automation and IIoT.

Portability & Durability

Designed for mobility, this trainer comes housed in a durable ABS plastic case with wheels and a handle for easy transportation. Setup is quick and intuitive—just remove the cover, and the trainer is ready to use.

World-Class eLearning

Amatrol’s interactive multimedia curriculum includes voiceovers, videos, 3D animations, and quizzes to make learning engaging and effective. Topics like predictive maintenance, Lean Manufacturing, and smart sensor operation are brought to life with stunning visuals and real-world applications.

Student Reference Guide

The included Smart Sensors Student Reference Guide condenses the system’s technical content into a bound book, creating an invaluable takeaway for learners to reference long after completing their training.

Start Building Industry 4.0 Expertise Today!

Download the brochure to discover how the Portable Smart Machine Sensor Learning System can transform your training program. Explore its cutting-edge features, innovative curriculum, and unparalleled ease of use.

Amatrol’s Portable Smart Process Sensor Learning System (990-SD20) teaches the operation and function of a variety of smart process sensors, including smart analog pressure sensors, smart electromagnetic flow sensors, smart ultrasonic level sensors, and smart point level sensors. Students will also gain an understanding of the Industrial Internet of Things (IIoT) and cloud computing.

This portable system provides hands-on experience with real-world components, including an IO-Link Master, smart sensor PC software, and applications for analog flow, analog level, and hi/lo level sensing. Students will study industry-relevant applications and learn hands-on skills that will build a strong foundation for a successful career in a variety of industries that use advanced process control technologies.

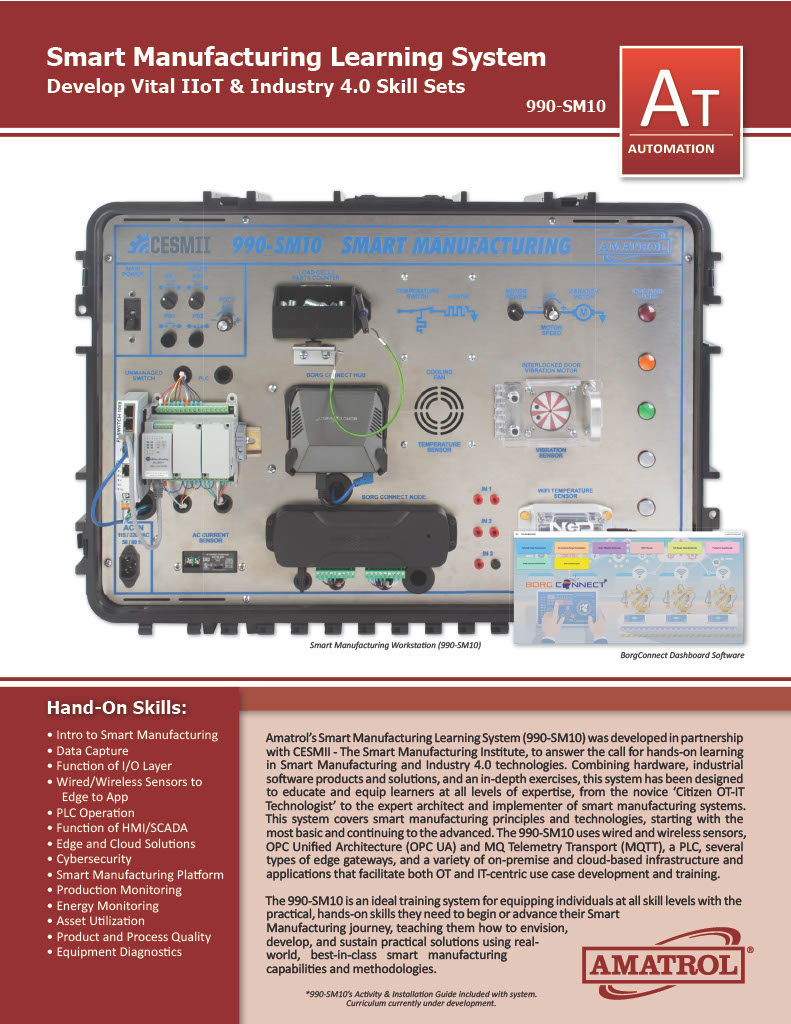

Amatrol’s Smart Manufacturing Learning System (990-SM10) was developed in partnership with CESMII - The Smart Manufacturing Institute, to answer the call for hands-on learning in Smart Manufacturing and Industry 4.0 technologies. Combining hardware, industrial software products and solutions, and in-depth exercises, this system has been designed to educate and equip learners at all levels of expertise, from the novice ‘Citizen OT-IT Technologist’ to the expert architect and implementer of smart manufacturing systems.

Proximity, Magnetic, & Photoelectric Sensors

Amatrol’s Portable Electronic Sensor Training System (990-SN1) teaches the operation of electronic, non-contact sensors and their applications in industry, such as sensing movement, detecting metal from non-metal, and determining speed. Packaged in a convenient, portable ABS plastic case, this system is perfect for use in small spaces or multiple locations.

The portable electronic sensors training system includes a variety of electronic sensors, including capacitive proximity, inductive proximity, magnetic reed, hall-effect, and photoelectric sensors. These sensors can be used with a large array of provided test materials to learn how each sensor completes industrial tasks in real-world environments. Combined with Amatrol’s world-class multimedia curriculum, this innovative product provides learners with a thorough understanding of electronic sensor applications.

Tabletop Mechatronics Option

Add Amatrol’s Stepper Motor Programming Package (45058) to the Smart Factory Tabletop Mechatronics System to teach valuable motor programming skills.

Amatrol’s Smart Factory Tabletop Mechatronics System provides a fantastic introduction to Industry 4.0 training for high schools. When training space or budget limitations don’t allow for installation of a full Mechatronics line, the Smart Factory Tabletop Mechatronics System packs a wide variety of essential training topics and hands-on skills into an affordable, compact training system.

Amatrol’s Combined Refrigeration Installation Learning System (T7200) offers a comprehensive hands-on workstation and interactive multimedia curriculum to teach installation of electrical and mechanical refrigeration/air conditioning components in residential or light commercial applications. This system in an ideal training tool for future HVACR technicians.

The Combined Refrigeration Installation Learning System includes evaporator and condenser coils, a hermetically-sealed compressor, a filter/drier, and many more real-world industrial components that allows learners to practice skills with components that they’ll find on-the-job. The included multimedia curriculum covers topics like: copper tubing, refrigerant line routing and bending, flaring and swaging copper tubing, brazing and soldering refrigerant lines, and copper tubing insulation.

Amatrol’s Residential Mini-Split Heat Pump Learning System (T7130) teaches the critical hands-on skills HVACR technicians need to succeed when working with residential ductless (“mini-split”) HVAC systems. Learners will work with real equipment, such as: a heat pump condenser, evaporator unit, thermostat, panel-mounted gauges, and condensate pump.

In addition to developing hands-on skills with real equipment, learners will use Amatrol’s interactive multimedia eLearning curriculum to cover a wide variety of fundamental residential mini-split system topics, including: remote controller adjustments, heating and cooling modes, LED indicators, communication between units, and system troubleshooting.

Hands-On Training for Tomorrow's Workforce

Marcraft has been providing technical training solutions for more than 40 years. Today, they focus on Cybersecurity & IT, GreenTechnology, Connectivity and Smart Technology Systems training programs. They engineer and design the training hardware training software and courseware materials necessary for success in your school classroom or career and technical education facility.