American manufacturing is growing faster than in decades, but a shortage of skilled laborers is stunting its full growth. The decline in trade school graduates over the past few decades has left a gaping hole in potential employees. Job openings remain unfulfilled as companies bend over backward to attract new talent to replace the current aging workforce.

These efforts, while noble, can quickly grow costly because of low labor retention and high turnover rates in the manufacturing industry. Adding in the fact that automation and robotics are replacing positions formerly held by humans, it is even more imperative that positions reserved for humans are filled by talented people.

How can manufacturing companies train new hires in cost-effective, engaging, and interesting ways that will encourage them to work longer in the industry? First, integrate VR training with traditional training—which is often conducted in classrooms or on the production line, taking senior employees away from their jobs. Virtual reality training provides manufacturers with the opportunity to simulate a production line environment before new laborers even hit the floor.

Virtual reality can train fresh hires or assess current employees on product assembly, hazard recognition, equipment handling, and more. Whichever way companies choose to utilize this technology, it holds the key to efficiency and future successes for manufacturers.

Every company knows how important it is to be compliant with OSHA protocols. Still, most are not aware of how to efficiently train their employees to follow these guidelines across various disciplines.

Traditional safety training can require costly outside instructors, time off the job, and pricey specialized equipment. Virtual reality, however, can help quickly familiarize novice and seasoned employees with updated safety protocols while saving time, money, and energy for both employer and employee.

Employees trained in these realistic, virtual environments will be familiarized with extreme heights, live wires, complex machinery, and more, helping them build muscle memory and retain pertinent information vital to on-the-job success. Using virtual reality as a training and assessment tool can give management a new perspective on improving their safety training.

System Overview and Compatibility

ABS-CF10 is currently available on the F123™ Series machines with 0.007 inch (0.178 mm), 0.010 inch (0.254 mm), and 0.013 inch (0.33 mm) layer heights. It requires a dedicated ABS-CF10 extrusion head, denoted with a dark green case, for all layer heights for the model material. It is compatible with QSR Support™ as a soluble support system and requires a standard F370™ extrusion head for all layer heights for the support material. This system uses the standard F123 Series build tray. ABS-CF10 and QSR are available in a standard F123 90-cubic-inch spool.

Stratasys ABS-CF10 combines standard ABS (acrylonitrile butadiene styrene) material with 10% chopped carbon fiber by weight.

The result is a low moisture-sensitive FDM® thermoplastic 50% stiffer and 15% stronger than standard ABS 3D printing material.

Typical applications include manufacturing tools, jigs, fixtures and end effectors that benefit from the combination of increased stiffness and reduced weight.

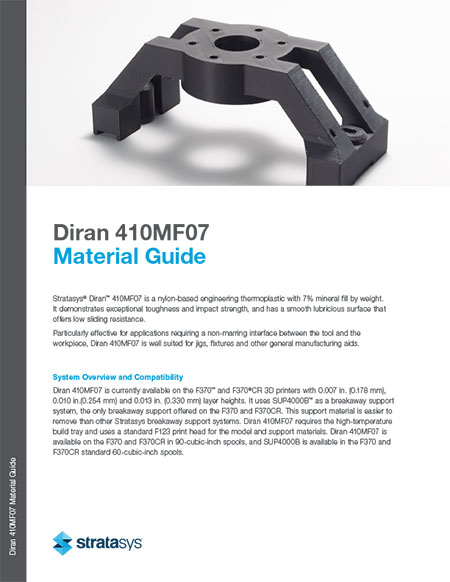

Diran™ 410MF07 is a nylon-based thermoplastic FDM® material, mineral-filled 7% by weight. It demonstrates very good toughness and impact strength combined with resistance to hydrocarbon-based chemicals. Its smooth, lubricious surface quality offers low sliding resistance.

Typical applications include jigs, fixtures and other forms of general manufacturing tooling, and is particularly effective for applications needing a non-marring interface between the tool and the workpiece.

Stratasys® Diran™ 410MF07 is a nylon-based engineering thermoplastic with 7% mineral fill by weight. It demonstrates exceptional toughness and impact strength and has a smooth lubricious surface with low sliding resistance.

Particularly effective for applications requiring a non-marring interface between the tool and the workpiece, Diran 410MF07 is well suited for jigs, fixtures, and other general manufacturing aids.

System Overview and Compatibility

Diran 410MF07 is currently available on the F370™ and F370®CR 3D printers with 0.007 in. (0.178 mm), 0.010 in.(0.254 mm) and 0.013 in. (0.330 mm) layer heights. It uses SUP4000B™ as a breakaway support system, the only breakaway support offered on the F370 and F370CR. This support material is easier to remove than other Stratasys breakaway support systems. Diran 410MF07 requires the high-temperature build tray and uses a standard F123 print head for the model and support materials. Diran 410MF07 is available on the F370 and F370CR in 90-cubic-inch spools, and SUP4000B is available in the F370 and F370CR standard 60-cubic-inch spools.

Overview of Stratasys FDM 3D Printers and Materials

FDM® (fused deposition modeling) 3D printers offer unparalleled versatility to turn your CAD files into durable parts. These parts are tough enough to be used as advanced conceptual models, functional prototypes, manufacturing tools, and production parts. Engineers can produce various products just by loading different files and materials. No traditional machining process can do that.

Handling & Finishing ABS-ESD7 Parts

Overview

ABS-ESD7 (static dissipative) material is among the many great materials available for the Fortus systems. This paper will walk you through the handling considerations for ABSESD7, including finishing, safety, and packaging guidelines.

Finishing

This material's most common finishing techniques are bonding and smoothing. For smoothing, sanding is the recommended method. As with all FDM materials, standard sanding processes can be followed. Unlike our standard ABS materials, note that this material cannot be smoothed using the finishing touch station. ABS-ESD7 can easily bond through typical methods, including solvents, epoxies, hot-air welding, ultrasonic welding, and superglue.

ABS-ESD7™ (acrylonitrile butadiene styrene-electrostatic dissipative) is an ABS thermoplastic with static dissipative properties suited for static discharge-sensitive applications. ABS-ESD7 prevents static electricity buildup, so it will not produce a discharge or attract other materials like powders, dust, and fine particles.

The material is ideal for jigs and fixtures used to fabricate and assemble electronic components and associated production line and conveyor parts. It is also useful for producing functional prototypes, enclosures, and packaging.

Pages

-

Item Number:950-TGC1Master wind turbine generator control with Amatrol’s 950-TGC1 training system. Hands-on troubleshooting, fault insertion, and realistic grid integration skills for future wind techs.

-

The Warehouse Working from Heights simulation is ideal for future employees or supervisors who work in or around warehouse operations.

-

Item Number:200-2203DAC Worldwide’s Wrap-Spring Clutch Sample (200-2203) depicts a modified industrial in-line, wrap-spring-type clutch for mechanical drive training in a classroom or laboratory.

-

Unitree Z1 is a super-lightweight robotic arm with great payload capacity designed for Unitree robot dogs. It can cooperate with AlienGo or B1 quadruped and other mobile robots to complete complex tasks and explore various scenarios.

-

Item Number:CO3221-6XOur newest Hybrid and Electric vehicle trainer now covers all topics related to the New ASE L3 test. Allow your students to build confidence by knowing they can safely work on a state-of-the-art real-world system that performs the procedures needed for both hybrid and electric vehicles.

-

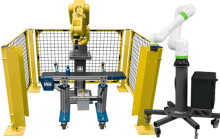

Item Number:AD2446-20The ClassMate® M cell is a complete robotic training solution designed to meet the need for advanced manufacturing training. Instructors can teach robotic concepts in the classroom and quickly move to the lab for welding practice.

-

DAC Worldwide’s selection of furniture offers a variety of solutions for creating flexible and functional training areas. Designed to work with DAC Worldwide's training systems, cutaways, models, and dissectibles, available furniture options allow you to create workstations, displays, or storage areas.

-

GrabCAD Print is a complete solution for Stratasys 3D printers. The intuitive, easy-to-use software simplifies preparing, scheduling, monitoring, and reporting print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management.

-

Item Number:400-PAC

DAC Worldwide’s Basic Electricity Training System Plus (400-PAC) examines basic AC and DC electrical principles. Learners will explore how electricity is used for power and control in various sectors, including industrial, commercial and residential applications. The training covers industry-relevant skills, such as installing, operating, and troubleshooting AC and DC electrical circuits in a variety of applications.

-

Safety fencing, conveyors, robot pedal stools, and CRX mobile carts