Wind Energy Technology Foundational Skills

Wind energy is a significant source of power that is growing dramatically. The Department of Energy has set a goal for 20% of electrical energy used in the United States to be from wind power by 2030. Wind farms can be found throughout the world – from cold, arctic conditions to the tropics, from beaches to mountains to oceans. Understanding the basics of how wind energy is harnessed will prepare technicians, engineers, installers, designers, builders, and others that want to utilize wind technology in either large utility-scale turbine farms or small wind applications.

Amatrol’s Wind Concepts Learning System (950-WC1) introduces learners to a broad range of basic concepts in wind energy technology. Learners study how wind power systems work and what it takes to generate electrical power with wind. Wind Concepts training acts as a foundation for learners enrolled in wind-specific as well as general renewable energy programs.

Hands-On Gas Metal Arc Welder Skills

Welding plays a critical role throughout our economy. It is central to many industries including manufacturing, construction, and aerospace to name only a few. GMAW Welding is a blend of both art and science, joined together to create enduring bonds that allow us to create structures and machines on a scale impossible to achieve without it.

Amatrol’s Welding Technology Learning System (950-WT1) teaches how to safely create an array of high quality weld types. This welding training system consists of a workstation with a self-contained down-draft table and angle grinder, storage station, gas metal arc welder (GMAW), weld test fixture, tools and fixtures, safety gear, student curriculum and teacher’s assessment guide. This industrial welding training system is mobile with both the workstation and storage unit designed for classroom use. These industrial-grade components are an example of Amatrol’s commitment to providing top-flight equipment and gives learners the opportunity to practice and gain experience on actual mechanisms that they’ll work with on the job.

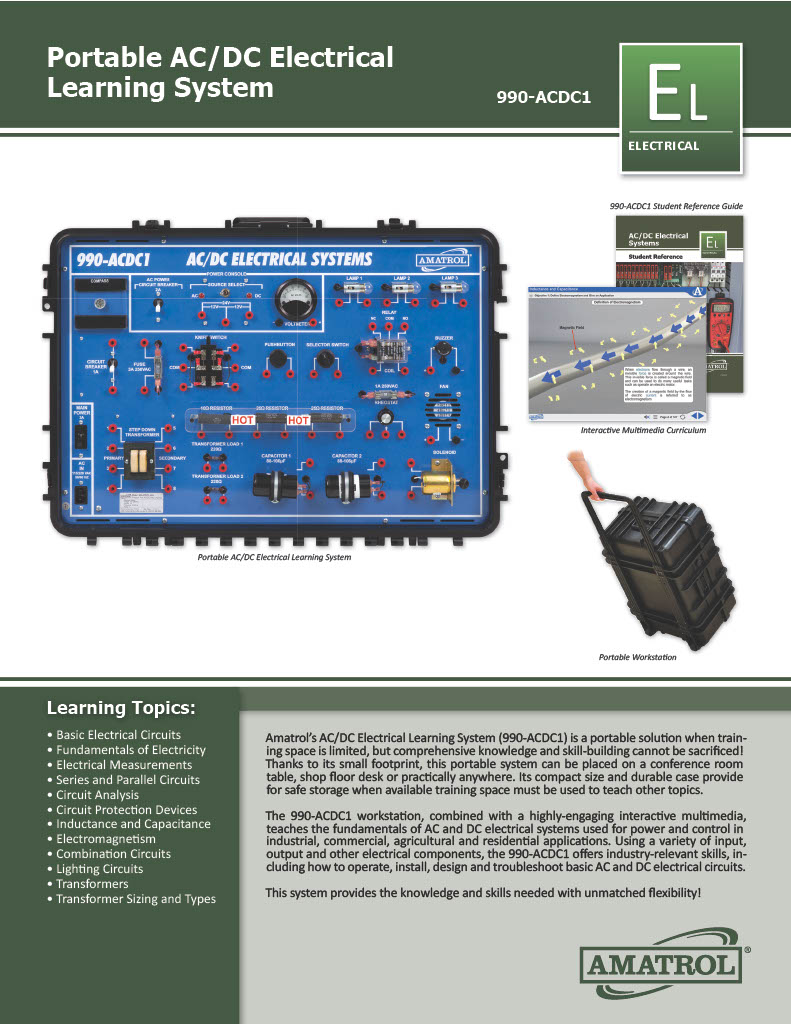

Amatrol’s Portable AC/DC Electrical Learning System (990-ACDC1) teaches the fundamentals of AC and DC electrical systems used for power and control in industrial, commercial, agricultural, and residential applications. The 990-ACDC1 offers industry-relevant skills including how to operate, install, design, and troubleshoot basic AC and DC electrical circuits for various applications.

This portable AC/DC electrical learning system brings customers flexibility and convenience when there’s a need to use a trainer in multiple locations or where space is too small for a full-size trainer. Set within a durable ABS plastic case, the 990-ACDC1 features wheels and a handle to create a completely mobile learning system. This highly efficient learning system also includes a lock for safety and a storage pouch in the inside cover for loose components, such as banana leads. The system’s front cover is easily removed, enabling the case to sit upright on a flat surface.

The 990-ACDC1 includes a variety of switches and other components so learners can build different circuits, which will help them to recognize industrial component styles and learn how to troubleshoot them effectively. Combined with Amatrol’s world-class curriculum, this innovative product can provide learners with a thorough understanding of electrical power.

Amatrol's Portable Electric Training System (990-ACDC1) is a great way to train electric concepts. Partnered with interactive multimedia, this learning system is a good cornerstone to any program.

Amatrol’s Portable Basic Hydraulics Training System (990-BH1) allows learners to gain skills by studying topics like basic hydraulic circuits, pressure control circuits, hydraulic schematics, and sequence valves. Also, given the compact nature of the Portable Basic Hydraulics system, for the first time you can teach hydraulics in a limited space. This learning system allows learners to study and practice how to read a pressure gauge, as well as liquid level and temperature in the reservoir, connecting hydraulic circuits, operating a bi-directional hydraulic motor, converting between absolute and gauge pressure, and connecting and adjusting the pressure setting of a pressure relief valve (PRV).

The mobile Basic Hydraulics training includes gauges, manifolds, cylinders, valves (relief/sequence, pressure reducing, check, directional control, etc.), flow meter, and hydraulic motor. The components of this portable trainer are all industrial quality, not only to ensure durability, but also to help learners become better prepared for what they will encounter on the job. All Amatrol products are made from top-notch materials and carefully crafted to create tough, attractive, well designed learning systems that facilitate learning and will serve teachers and learners for years. Amatrol uses components that learners will find on-the-job in order to give the best opportunity to build confidence and industrial competencies.

Amatrol’s Portable AC Variable Frequency Drives Troubleshooting Learning System (990-DRV1F) teaches the fundamentals of configuring and operating an AC variable frequency drive. The AC motor drive troubleshooting system includes industry-standard components, such as an Allen-Bradley PowerFlex 4 variable frequency AC drive and a 3-phase AC motor, in a convenient, portable case that can be used virtually anywhere.

The system also features FaultPro, Amatrol’s exclusive electronic fault insertion software. FaultPro allows users to learn motor drive troubleshooting skills, such as drive input, motor input, and drive relay troubleshooting. FaultPro allows users to troubleshoot realistic situations they will encounter on the job in industries like packaging, textiles, and paper where rapid motor acceleration and deceleration are required.

Amatrol’s Portable Electric Relay Control Troubleshooting Training System (990-EC1F) covers concepts widely used in industrial, commercial, and residential applications to regulate electric motors and fluid power actuators, as well methods used for troubleshooting problems in relay control components and systems. This portable learning system offers learners flexibility and convenience when there’s a need to use a trainer in multiple locations or where space is too small for a full-size trainer.

The 990-EC1F includes a relay control panel with pre-mounted electrical control, pneumatic, and electric power components. Learners can use these components to connect electrical terminals to heavy-duty banana jacks to test various automation control circuits. This system also includes a digital multi-meter that will be used for troubleshooting concepts and skills. Combined with Amatrol’s world-class interactive multimedia curriculum, this innovated product can provide learners with a thorough understanding of electric relay control.

Amatrol’s Portable Power and Control Electronics Learning System (990-ELE1) teaches learners how to operate, adjust, and troubleshoot electronic components, circuits, and systems used in machine applications. This powerful training system allows users to explore the fundamental concepts of industrial power and control electronics, such as measuring temperature, speed, and analog signals, in a convenient, compact unit that can be easily transported for use in multiple locations.

The 990-ELE1 features a wide variety of industry-standard electrical components and circuits that can be set up in a wide variety of real-world machine applications. These components will help learners gain hands-on experience with linear power supplies, solid state relays, discrete and thermal sensing devices, solid state switching, and more! The 990-ELE1 also utilizes FaultPro, the industry’s premier computer-based fault insertion system that enables learners to develop key industry troubleshooting skills. FaultPro features 30 different faults to present learners with realistic troubleshooting experiences.

Amatrol’s Portable Electric Motor Control Troubleshooting Learning System (990-MC1FSL) features standard industry components like a 3-phase AC squirrel cage motor and uses 3-phase AC for power and 24 VDC for control all packed within a space-saving, portable product. These real-world motor control components will prepare learners for work opportunities in industries where electric relay control is used in applications like conveyor control and driving large utility pumps. Teach students how to read and interpret ladder diagrams. The 990-MC1FSL also uses FaultPro, Amatrol’s unique electronic fault insertion, to teach motor control troubleshooting skills, such as control relay, reversing contactor, limit switch, and pushbutton troubleshooting.

The 990-MC1FSL uses industrial components to cover the operation, installation, and applications for electric relay control of AC motors all within this portable, durable learning system that can be set up nearly anywhere. This system also builds knowledge and skills across topics like manual motor control, control ladder logic, motor starters, and automatic input devices. Nowhere else can you find this breadth of training in a portable platform!

Amatrol’s Portable Mechanical Drives 1 Learning System (990-ME1M) covers the fundamentals of mechanical transmission systems and applications, such as how to: operate, install, analyze performance, and design basic mechanical transmission systems using chains, vbelts, spur gears, bearings, and couplings. These mechanical system fundamentals can be applied to a variety of applications within the automotive, agricultural, and power industries.

The 990-ME1M includes: a tabletop mounting work surface; a drive motor; a variety of components for belt, chain and gear drives; a digital tachometer; a mechanical load device; and an alignment package. This power transmission training system uses industrial quality components to help assure that learners are better prepared for what they will encounter on the job and to withstand frequent use. These components will be used to cover major mechanical drives topics like shaft speed measurement, key fasteners, power transmission systems, belt drive concepts, chain tensioning, and gear backlash. The 990-ME1M features the ability to set up various drive systems, showing learners the effects of proper alignment and how to obtain best efficiency.

Pages

-

Item Number:T7022Train the next generation of EV workforce with the Amatrol T7200 EV Battery Technology Training System. Hands-on skills in safety, diagnostics, disassembly, and troubleshooting prepare learners for electric vehicle careers.

-

Item Number:271KThe Extended Dissectible Valve Assortment features actual industrial valves that industrial maintenance technicians will commonly encounter on the job.

-

Item Number:464EDAC Worldwide’s Extended PLC Trainer (464E) is a multi-use training platform allowing for instruction related to the programming and use of industrial PLCs.

-

Item Number:203EIndustrial maintenance technicians must learn to operate, maintain, troubleshoot, and repair a wide variety of mechanical systems used to manufacture products. One of the key diagnostic tools technicians will use during preventive maintenance as well as to maintain optimum efficiency is vibration analysis.

-

Item Number:295-795EDAC Worldwide’s Extended Wellhead Assembly Cutaway (295-795E) depicts the complete assembly of components used in creating a wellhead.

-

Item Number:275-135DAC Worldwide’s External Gear Pump Dissectible (275-135) is a realistic industrial pump for use in classroom and laboratory training relating to process pumps.

-

Item Number:778-110DAC Worldwide’s Hydraulic Gear Pump Cutaway, External-Type (778-110) is an industrial hydraulic gear pump that has been sectioned to reveal the inner workings of this component. This exposure allows learners to understand the design, operation, construction, and maintenance of this common process pump used throughout the industry.

-

Item Number:F190CR and F370CRIt starts with high-strength composite materials, but the Stratasys composite-ready F Series offers much more. More materials, more reliability – more capability than other similar printers.

-

The Fall Protection awareness simulation is ideal for future employees and supervisors who will work in or around construction environments. The primary goal of this course is to teach workers safe procedures when working at heights on a construction site.

-

Item Number:202-000DAC Worldwide’s Fan Balancing Trainer (202-000) is a precision assembly allowing for convenient demonstration and training in fan balancing and other vibration analysis-related topics. Based on the design of a typical squirrel cage fan, this heavy-duty aluminum device allows for assembly in a variety of configurations, creating a broad range of balancing scenarios.