One hundred parts produced within 24 hours on a single Origin One, at a fraction of the cost of traditional manufacturing.

Origin® One features several integrated cameras for computer vision and capturing temperature data in the IR range; additional sensors measure other environmental conditions during the print process.

Senior mechanical design engineer Matt Miyamoto designed camera mounts for CNC machining out of black ABS plastic. A compound angle meant that the part could only be machined by a 5-axis CNC (or on a 3-axis CNC with multiple setups), which made the parts expensive to machine at low or high volumes. Matt turned to Origin’s solution to achieve the quality and throughput required.

Slashing costs, improving performance: Medical device development and manufacturing with the Stratasys Origin One

Case Study: Enventys Partners, a full-service, turnkey product launch agency, delivered end-use biocompatible devices, while avoiding the long lead time, high costs and design constraints of injection molding or CNC machining by printing with the Stratasys Origin One.

Producing Lightweight, Durable Robot Parts on Stratasys Origin One

Ghost Robotics™ produces four-legged autonomous unmanned robots with all-terrain stability that can operate in almost any environment. These quadruped robots are size-scalable, ultra-agile, high-endurance, and easy to program. Simple mechanical systems increase the robots’ durability, agility, and endurance. The robots’ modular design supports the efficient field swapping of any sub-assembly.

Challenge

Ghost Robotics needed to produce lightweight, durable parts, with a cosmetic surface finish, for its Spirit™ Series robot.

- The team needed to stay agile, shipping units to customers while maintaining the ability to iterate designs based on customers’ feedback.

- Injection molded parts and CNC machined parts were cost-prohibitive, had long lead times, and could not be easily iterated on.

- The company considered other 3D printing methods as a solution, but the parts weren’t isotropic the mechanical properties weren’t strong enough; and the surface quality was too rough for the parts to be given to customers.

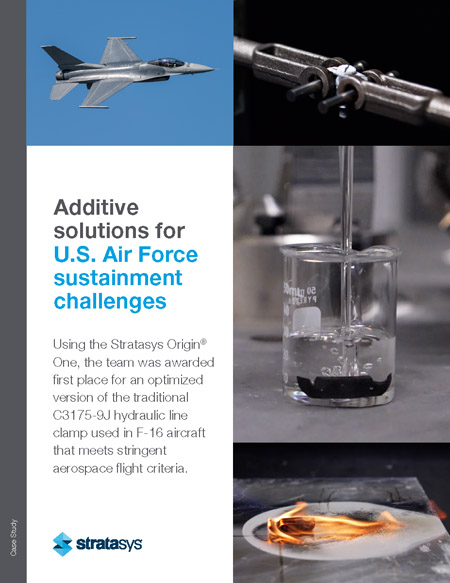

Ongoing sustainment for aging aircraft components

The U.S. Air Force increasingly faces sustainment challenges, including cost, speed, and supply chain agility, when using traditional manufacturing methods to maintain aging aircraft components. The department often seeks innovative engineering solutions to keep aircraft aloft and to modernize the fleet. In 2020, they hosted an open competition to quickly find new and creative 3D printing solutions for the C3175 family of hydraulic line clamps. Thousands of these clamps are used in the Air Force’s F-16 aircraft, in areas like landing gear cavities, and they frequently fail after extended exposure to vibration, environmental chemicals, and heat cycling. Historically, these clamps have been injection molded or CNC machined from a phenolic material that off-gases toxic formaldehyde.

The Origin One printer is designed to be a safe and reliable rapid prototyping printer. Access to areas of the printer is potentially dangerous. Download the Stratasys Origin One Instruction for Safe Use.

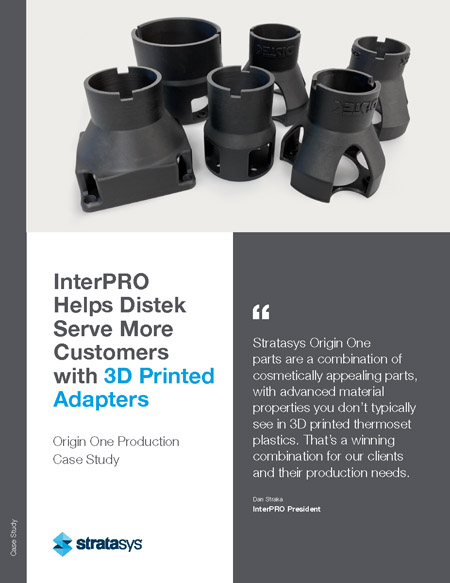

InterPRO Helps Distek Serve More Customers with 3D Printed Adapters

InterPRO Additive Manufacturing Group, a service bureau, started as a 3D printing prototyping company and is seeing growth in production applications due to advancements in 3D print technology and materials. InterPRO’s client Distek, a leading manufacturer of laboratory testing instruments for the pharmaceutical and biotechnology industries, asked InterPRO to help them manufacture a motor adapter that would allow prospective customers to use Distek’s technology with customers’ existing motors. InterPRO used Stratasys’ Origin® One’s next-generation 3D printing hardware and software to print parts compatible with Distek’s bioreactor and their client’s devices. The parts had injection molded-like strength, consistency, and durability. The surface finish had an impressive, consumer-grade look and feel.

Distek’s challenge was to produce a motor adapter compatible with their proprietary bioreactor and their clients’ motors. However, the adapter design wasn’t easily manufacturable by CNC machining, injection molding, or even cast urethane. In addition, the company needed a fast turnaround to meet immediate customer needs for various adapter sizes in low volumes. High up-front tooling costs, long lead times, and low-volume demand ruled out traditional methods. As a result, InterPRO turned to 3D printing as a possible solution.

LOCTITE 3D 3172 is a durable photopolymer resin that enables functional parts production where high stiffness with a good surface finish and high impact resistance are required. Parts manufactured with this resin can be machined, tapped or polished.

LOCTITE 3D 3172 is compatible with various DLP machines.

Benefits:

- Tough & durable

- Superior impact strength

- Nice surface finish, machine-able

Ideal for:

- Manufacturing aids / Jigs & Fixtures

- Housings

- Insoles

HDT60 High Toughness Photoplastic

Matte Black, White, Clear

LOCTITE 3D 3843 is a semi-flexible resin with moderate temperature resistance HDT60, high impact strength, and versatility for various applications.

LOCTITE 3D 3843 is a high-strength engineering plastic with good impact resistance and surface finish. It is ideal for many different tooling applications on the production floor.

LOCTITE 3D 3843 displays high green strength and HDT enabling it to print accurately and function at room temperature. It is compatible with a broad range of DLP machines.

Benefits:

Ideal for:

HDT280 FST Photopolymer

Black

LOCTITE 3D 3955 is a halogen-free, high-performance, high-modulus material with excellent flexural and tensile physical properties.

LOCTITE 3D 3955 passes UL94 V-0 flammability requirements, and FST (AITM2-0002, AITM2-0007, AITM3-0005) and its high HDT allows it to withstand harsh environments with negligible deformation.

Parts printed with LOCTITE 3D 3955 showcase an excellent surface finish making it ideal for connector and interior parts for aerospace and rail.

Benefits:

- Fire Safety Material

- Halogen Free

- Excellent flexural and tensile physical properties

Ideal for:

- HVAC Components for Aircraft

- Clips and Plugs for Control Systems/Cabinets

- Connectors, Electronic Housings

HDT80 High Modulus Photo plastic

Black

LOCTITE 3D IND403 is a high-temperature resistance material that allows the production of parts with high surface quality and outstanding dimensional accuracy. It is ideal for tooling production for processes such as silicone casting, low-pressure molding, and open-mold PU molding. The material can withstand mechanical stresses while maintaining dimensional stability for multiple cycles for fast product development and rapid process iteration.

Benefits:

- High heat deflection temperature, HDT 80oC

- Tough with good dimensional stability

- Good surface finish

Ideal for:

- Tooling and molds

- Interior applications in automotive