Somos® BioClear has passed cytotoxicity, irritation, sensitization, and USP VI. A toxicological profiling of the components has been performed. A Device Master File to support this material is accessible through the FDA. Ask a sales representative for more information.

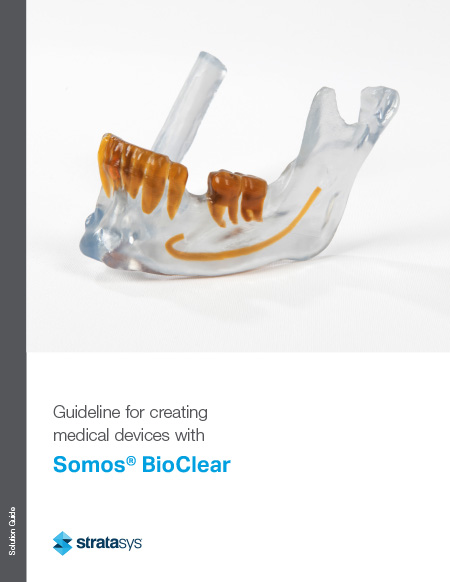

Steps in the production process of 3D printed parts can influence the final part safety. This document gives guidance on areas to pay attention to when using Somos® BioClear.

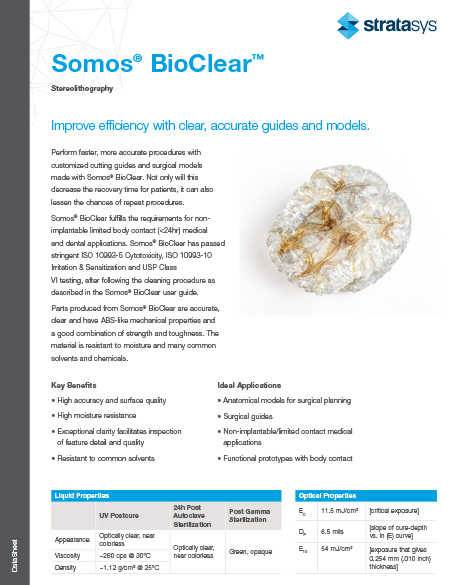

Improve efficiency with clear, accurate guides and models.

Perform faster, more accurate procedures with customized cutting guides and surgical models made with Somos® BioClear. Not only will this decrease the recovery time for patients, it can also lessen the chances of repeat procedures.

Somos® BioClear fulfills the requirements for non-implantable limited body contact (<24hr) medical and dental applications. Somos® BioClear has passed stringent ISO 10993-5 Cytotoxicity, ISO 10993-10 Irritation & Sensitization, and USP Class VI testing, after following the cleaning procedure as described in the Somos® BioClear user guide.

Parts produced from Somos® BioClear are accurate, clear and have ABS-like mechanical properties and a good combination of strength and toughness. The material is resistant to moisture and many common solvents and chemicals.

Fast and easy production of quality hollow composite tooling parts, that are easy to remove after the autoclave process.

While basic composite shapes with constant cross sections are easily manufactured using traditional composite manufacturing techniques, complex parts with hollow interiors present a unique challenge. Additive manufacturing has fundamentally changed the process. High-temperature, cost-effective tools can now be produced in days, compared to the weeks or even months required for traditional tooling, and provides a cost-effective solution even for small series production.

Somos® DMX SL-100, a durable and tough stereolithography (SL) resin, is an efficient and cost-effective solution that produces very accurate parts with a superb surface finish and high feature detail, promoting greater design freedom for composite applications.

Somos® DMX SL-100 withstands the high temperatures utilized in the autoclave process for composites manufacturing maintaining its flexural strength, elongation and tear resistance. These unique properties allow, at a certain temperature, for mandrels to be removed from complex and convoluted geometries through a “dry removal” process which is unique for a solid mandrel. Other soluble wash out cores need submerging in caustic which can affect the composite part. No other material in the industry is as easily and best removed after the autoclave process, facilitating the more efficient production of complex, hollow composite parts.

This method of using additive manufacturing to produce sacrificial tooling is straightforward and enables multiple iterations to be implemented quicker by the user.

In partnership with Covestro Additive Manufacturing (formerly DSM) and its Somos® resins, the Neo 3D printers can run the most technically advanced stereolithography materials.

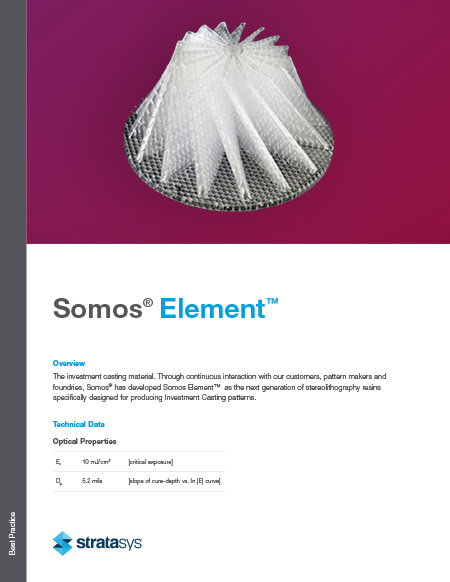

A stereolithography material engineered to create flawless investment castings patterns.

Through continuous interaction with our customers, pattern makers and foundries, our team developed Somos® Element for producing investment casting patterns.

Somos® Element is an antimony-free stereolithography material specifically designed to improve the repeatability and quality of 3D printed casting patterns. Patterns created with Somos® Element leave trace amounts of lightweight, easily-removable ash residue after burnout and have better green strength, so there’s no worry of breakage during handling, while being dimensionally stable during storage. Any residue left behind is easily removed, leaving a perfectly clean void in the ceramic mold. This translates into lower mold prep times and lower rates of rework, saving customers time and money.

Key Benefits

- Trace amounts of ash that are lightweight and easily removed

- Suitable for high-end alloy castings

- Rapid draining

- Produces accurate, repeatable parts regardless of size

A resin offering durability and fast processing times.

Somos® EvoLVe 128 is a durable stereolithography material that procudes accurate, high-detailed parts and has been designed for easy finishing. It has a look and feel almost indistinguishable from finished traditional thermoplastics, making it excellent for building parts and prototypes for functional testing applications – resulting in time, money, and material savings during product development. Somos® EvoLVe is an excellent material for industries such as aerospace, automotive, medical, consumer products, and electronics.

Key Benefits

- Easy to clean & finish

- High strength & durability

- Accurate & dimensionally stable

- High detail

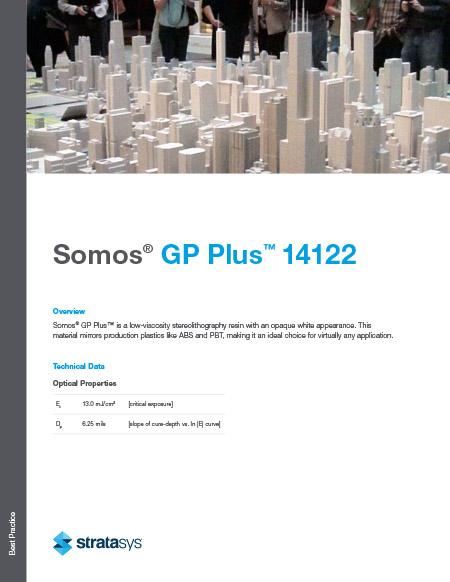

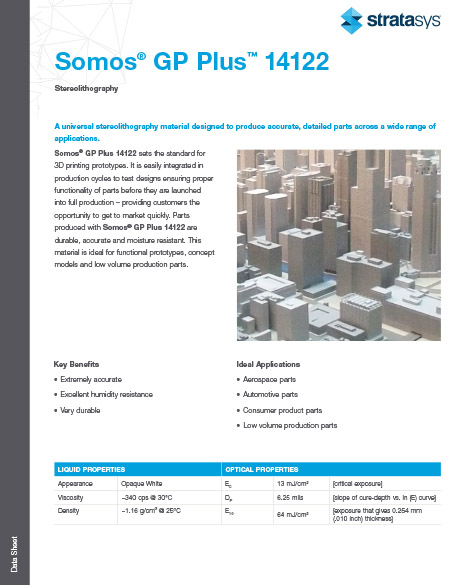

A universal stereolithography material designed to produce accurate, detailed parts across various applications.

Somos® GP Plus 14122 sets the standard for 3D printing prototypes. It is easily integrated in production cycles to test designs ensuring proper functionality of parts before they are launched into full production – providing customers the opportunity to get to market quickly. Parts produced with Somos® GP Plus 14122 are durable, accurate and moisture-resistant. This material is ideal for functional prototypes, concept models, and low-volume production parts.

Key Benefits

- Extremely accurate

- Excellent humidity resistance

- Very durable

Pages

-

Item Number:773-195DAC Worldwide’s Bladder Accumulator Cutaway is a professionally-crafted hydraulic accumulator cutaway that supports training in the application, design details, and operating principles of hydraulic accumulators commonly found with hydraulic systems.

-

Item Number:295-716DAC Worldwide’s Blowout Preventer (BOP) Cutaway (295-716) depicts the sectioned blowout preventer for training in the operation, construction, and maintenance of this common oilfield safety device.

-

BÖHLER offers powders with the right properties for every application and printing technology. In it's global development and testing center we produce test objects with 3D printing in order to acquire experience and explore new application areas for additive manufacturing of components.

-

Item Number:240-PACDAC Worldwide’s Boiler Tube Maintenance Training System Plus (240-PAC) is a heavy-duty unit perfect for either classroom or lab training. Users will gain critical hands-on skills in the removal and installation of fire tubes in fire-tube boilers.

-

Item Number:240-000DAC Worldwide’s Boiler Tube Trainer (240-000) is a heavy-duty fixture for convenient classroom or laboratory training in the removal and installation of tubes in industrial fire tube boilers. Based on the geometry and materials of a common Scotch marine boiler, this device allows for repeated practice in the maintenance of tubes without jeopardizing actual equipment, or consuming unnecessary floor space.

-

Item Number:220-000DAC Worldwide’s Brake Clutch Trainer (220-000) is a complete, motorized training package of brake and clutch-related hardware and control components.

-

Item Number:220-PACPDAC Worldwide’s Brake Clutch Training System (220-PACP) is a complete, motorized training package of brake and clutch-related hardware and control components.

-

Item Number:DZRSimlog's Bulldozer simulation software can also be configured, in order to simulate the behavior of a wide variety of bulldozers. For example, you can use separate pedals for Decelerator and Brake, or just a single pedal that combines both functions, to reproduce the different pedal arrangements found in real bulldozers.

-

Item Number:254DAC Worldwide’s Butterfly Valve Cutaway, 4” - 6” (254) is a sample industrial butterfly valve that has been carefully sectioned and color-coded to train learners in the operation, construction, and maintenance of butterfly valves. The cutaway exposes and showcases the complete internal configuration of an industrial butterfly valve. Moreover, seal features and hardware locations have been retained to allow realistic, hands-on valve maintenance training.

-

Item Number:701-02 / 720-02 / 711-01LJ Create's CAN Systems Desktop Trainers give students an introduction to CAN systems and provide them with the working knowledge to diagnose and solve CAN bus problems.