TacMed’s Upper Body Simulators provide advanced, high-fidelity training for emergency trauma care focused on the head, neck, chest, and arms. Designed to mimic realistic injuries such as airway obstructions, gunshot wounds, and severe bleeding, these simulators allow medical professionals and first responders to practice life-saving procedures in controlled environments. With features like airway management and wound packing, TacMed's Upper Body Simulators ensure that trainees gain hands-on experience, building the skills necessary for quick and effective intervention in critical situations.

These simulators are ideal for both classroom training and field exercises, enabling users to perform realistic medical care under simulated high-pressure conditions. By focusing on the upper body, trainees can master crucial emergency techniques, improving their confidence and proficiency in managing a wide range of trauma scenarios.

TacMed’s Lower Body Simulators are engineered to replicate life-threatening injuries in the abdomen, pelvis, legs, and feet, giving medical professionals and first responders the opportunity to practice essential trauma care procedures. Featuring advanced technology for tourniquet application, hemorrhage control, and injury management, these simulators allow for hands-on training in both classroom and field environments. The realism provided by TacMed’s Lower Body Simulators prepares trainees to confidently manage critical injuries in real-world emergency situations.

By focusing on lower body trauma, these simulators help build essential skills in high-pressure environments, allowing users to practice critical interventions. From severe bleeding to complex fractures, TacMed’s Lower Body Simulators deliver comprehensive training experiences that improve preparedness and response times during emergencies.

Hands-On Training for Power & Utilities Professionals

Equip your workforce with the essential skills required to thrive in the power and utilities industry through a combination of hands-on, virtual, and e-learning training solutions. Our programs provide learners with practical experience in critical areas like electrical distribution, transformer connections, and safety protocols. With real-world, immersive training, participants will build the confidence needed to handle complex electrical systems, while mastering the core competencies that keep operations safe and efficient.

Whether learners prepare to install, maintain, or troubleshoot modern power systems, our comprehensive training ensures they are ready to meet industry demands. By developing technical expertise in a controlled and engaging environment, we help bridge the growing skills gap and prepare your team for the challenges of tomorrow’s energy infrastructure. Empower your workforce today and ensure long-term success in this essential industry.

Contact us today to discover how our training solutions can help develop your team's technical skills.

Unlock the Future of Welding with Robotic Solutions

Robotic welding is transforming the manufacturing industry by increasing productivity, improving weld quality, and reducing labor costs. Our comprehensive brochure dives into the latest advancements in robotic welding technology, providing insights into how automation can streamline your welding processes. From system integration to programming and operation, discover how robotic welding can enhance your workforce’s capabilities and meet growing production demands.

Download our brochure to learn more about how robotic welding solutions can help you stay competitive, boost efficiency, and ensure high-quality, repeatable welds across various applications. Equip your team with the skills needed to excel in automated welding today.

Join us at Tech-Labs’ Solutions Center Open House on October 24-25, 2024, to explore the latest advancements in technical training solutions! This exclusive event offers live demonstrations, hands-on experiences, and expert-led presentations from leading names in manufacturing and education. Whether you're an educator, industry professional, or student, you'll gain valuable insights into cutting-edge technologies like robotics, 3D printing, medical simulation, and more. Don't miss the chance to earn certifications and connect with experts shaping the future of technical education.

Download the event flyer to get detailed information about sessions, demos, and how to attend in person or virtually!

Join Tech-Labs’ SACA Webinar Series and learn how to establish a SACA Academy for industry-recognized certifications. Explore best practices, tools, and resources to prepare students for advanced manufacturing careers. Don’t miss out on this opportunity to enhance your technical training program!

Mastering the control of hazardous electrical energy is crucial to preventing workplace accidents. DAC Worldwide’s Electrical Lock-Out/Tag-Out Training System (Model: 810-000) provides hands-on, practical training designed to ensure that workers are fully equipped to identify, isolate, and safely deenergize electrical equipment. This portable training system replicates real-world industrial scenarios, giving workers the confidence to perform lock-out/tag-out (LOTO) procedures with ease. All training exercises operate at a reduced voltage of 24VDC, ensuring maximum safety during instruction while still providing a highly effective learning experience.

With this comprehensive system, users will have access to industry-standard lock-out/tag-out components, a complete lock-out/tag-out tool kit, and a detailed Use Guide that leads them through practical exercises. The training system is ideal for industrial safety programs, technical colleges, and vocational training centers aiming to enhance their electrical safety training. Download the Electrical Lock-Out/Tag-Out Training System PDF now to learn more about how this system can improve your organization’s safety protocols.

Download the PDF to explore the full features and specifications of the Electrical Lock-Out/Tag-Out Training System and see how it can benefit your safety training program today!

This video provides a detailed overview of DAC Worldwide’s Electrical Lock-Out/Tag-Out Training System, highlighting its key features and operational capabilities.

Safety is the cornerstone of any industrial environment, and mastering the control of hazardous energy, particularly electricity, is essential to prevent injury or death. Lock-out/tag-out (LOTO) procedures are critical for ensuring that machinery and electrical currents are properly deenergized, creating a safe workspace for employees. By following LOTO practices, workers can significantly reduce the risk of accidents caused by unexpected energy releases.

DAC Worldwide’s Electrical Lock-Out/Tag-Out Training System offers an affordable, portable solution designed for hands-on learning in industrial safety training. This tabletop trainer provides practical experience in identifying and securing dangerous electrical energy sources, operating at a reduced voltage to ensure user safety.

The system includes real-world components such as clamp-on circuit breaker lock-outs, a knife-type disconnect switch, an IEC rotary safety switch, a 3-in-1 plug lock-out, and more. Along with test points, indicator lights, and a comprehensive toolbox of locking and tagging devices, the system also features a detailed Use Guide to reinforce critical lock-out/tag-out procedures.

Understanding Carbon Capture: A Key to Reducing CO₂ Emissions

Carbon capture is a critical technology in the global effort to mitigate the impact of climate change. It involves capturing carbon dioxide (CO₂) emissions from industrial processes before they enter the atmosphere, reducing the greenhouse gases that contribute to global warming. These captured emissions are either stored or repurposed, preventing their release into the environment.

Industries such as power generation, manufacturing, and chemical processing are the largest producers of CO₂. By incorporating carbon capture technologies, these industries can significantly reduce their environmental footprint and help build a more sustainable future. The demand for skilled professionals who can implement these solutions is growing, and this is where advanced training systems come into play.

PIGNAT: Leaders in Carbon Capture Training and Research

PIGNAT is at the forefront of providing comprehensive educational and research solutions for carbon capture technologies. With over 50 years of expertise in chemical and process engineering, PIGNAT designs modular systems for training and research that address real-world challenges in CO₂ capture and reduction.

This range of teaching and research units are ideal for institutions, industrial research labs, and companies looking to upskill their teams or conduct advanced research in carbon capture technologies. These systems provide hands-on learning, allowing students, engineers, and researchers to simulate industrial processes, test various techniques, and refine CO₂ capture methods for greater efficiency.

At Tech-Labs, we pride ourselves on offering more than just cutting-edge training equipment—we provide full support from installation to troubleshooting, ensuring our customers have everything they need to succeed. In this video, Daniel Nolan, our Field Service Manager with over nine years of experience, walks through how his team assists educators and organizations in setting up and maintaining their training systems.

Daniel discusses the Amatrol training systems, known for their modular design and use of industry-standard components, preparing students for real-world industrial environments. Our support team not only helps with installation but also ensures that customers are comfortable using the equipment. From addressing safety concerns in training on three-phase power systems to guiding educators through detailed, step-by-step curriculum, Tech-Labs is committed to making technical training both accessible and effective.

Daniel also highlights the advanced mechatronics system—a capstone training solution that integrates AC/DC relay control, PLCs, fluid power, and robotics, giving students a full automation experience. These systems, paired with our collaborative robotics solutions, create a safe and interactive learning environment.

Why Choose Tech-Labs?

- Installation Services: Seamless setup and configuration of your new training systems.

- Support: Quick resolutions for any missing or damaged components and ongoing support to keep your system running smoothly.

- Curriculum Integration: Step-by-step curriculum to help educators and students maximize the potential of their equipment.

- Industry-Standard Equipment: Amatrol systems feature components commonly found in industrial environments, giving students hands-on experience with real-world tools.

At Tech-Labs, we're here to help you create the best learning environment for your students. With a team of dedicated professionals ready to assist, we ensure that every step of your technical training process is smooth and successful.

Contact Us today to learn more about how Tech-Labs can elevate your training programs.

Pages

-

Item Number:950-TGC1Master wind turbine generator control with Amatrol’s 950-TGC1 training system. Hands-on troubleshooting, fault insertion, and realistic grid integration skills for future wind techs.

-

The Warehouse Working from Heights simulation is ideal for future employees or supervisors who work in or around warehouse operations.

-

Item Number:200-2203DAC Worldwide’s Wrap-Spring Clutch Sample (200-2203) depicts a modified industrial in-line, wrap-spring-type clutch for mechanical drive training in a classroom or laboratory.

-

Unitree Z1 is a super-lightweight robotic arm with great payload capacity designed for Unitree robot dogs. It can cooperate with AlienGo or B1 quadruped and other mobile robots to complete complex tasks and explore various scenarios.

-

Item Number:CO3221-6XOur newest Hybrid and Electric vehicle trainer now covers all topics related to the New ASE L3 test. Allow your students to build confidence by knowing they can safely work on a state-of-the-art real-world system that performs the procedures needed for both hybrid and electric vehicles.

-

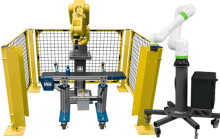

Item Number:AD2446-20The ClassMate® M cell is a complete robotic training solution designed to meet the need for advanced manufacturing training. Instructors can teach robotic concepts in the classroom and quickly move to the lab for welding practice.

-

DAC Worldwide’s selection of furniture offers a variety of solutions for creating flexible and functional training areas. Designed to work with DAC Worldwide's training systems, cutaways, models, and dissectibles, available furniture options allow you to create workstations, displays, or storage areas.

-

GrabCAD Print is a complete solution for Stratasys 3D printers. The intuitive, easy-to-use software simplifies preparing, scheduling, monitoring, and reporting print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management.

-

Item Number:400-PAC

DAC Worldwide’s Basic Electricity Training System Plus (400-PAC) examines basic AC and DC electrical principles. Learners will explore how electricity is used for power and control in various sectors, including industrial, commercial and residential applications. The training covers industry-relevant skills, such as installing, operating, and troubleshooting AC and DC electrical circuits in a variety of applications.

-

Safety fencing, conveyors, robot pedal stools, and CRX mobile carts