Explore Vapor–Liquid Equilibrium with Pignat Systems

Thermodynamics Meets Real-World Application

Understanding vapor–liquid equilibrium (VLE) is essential for designing separation processes. Pignat’s ebulliometer training systems allow students to investigate boiling points, azeotropes, and thermodynamic properties directly in the lab.

These systems bridge theory and practice, giving learners critical insight into the phase behavior that drives distillation and other chemical processes.

Key Learning Outcomes

- Measure and analyze boiling points under different pressures

- Explore azeotrope formation and its impact on separation

- Apply vapor–liquid equilibrium data to distillation design

- Strengthen thermodynamic understanding with hands-on training

Teach Industrial Evaporation in the Lab

Evaporation Experiments for Chemical Engineering Education

Evaporation is widely used in chemical, food, and environmental industries to concentrate solutions and recover solvents. Pignat’s evaporation training units provide hands-on learning of heat transfer, phase change, and energy efficiency.

These systems allow students to evaluate operating conditions and optimize processes, preparing them for practical applications in industrial environments.

Key Learning Outcomes

- Understand evaporation principles and heat transfer

- Study concentration and solvent recovery techniques

- Explore the role of energy efficiency in evaporation systems

- Connect theoretical concepts with real-world industrial practice

Liquid–Liquid Separation for Education & Research

From Theory to Application: Extraction Education

Liquid–liquid extraction is a versatile separation technique, commonly applied in pharmaceuticals, environmental engineering, and chemical production. Pignat extraction units give students a hands-on platform to explore solvent recovery, phase equilibria, and distribution coefficients.

By operating real equipment, learners connect theoretical concepts to industrial practices, gaining valuable process engineering skills.

Key Learning Outcomes

- Understand phase equilibria in liquid–liquid systems

- Perform separation and purification through extraction

- Study solvent recovery and distribution coefficients

- Apply liquid–liquid extraction to real industrial challenges

Explore Solid–Liquid Separation Hands-On

Pignat Filtration Systems for Education & Research

Filtration is a core separation method across industries, from chemical production to environmental management. Pignat’s filtration training units let students experiment with solid–liquid separation, pressure effects, and filtration media.

These systems prepare learners for real-world challenges by linking academic knowledge with industrial filtration applications.

Key Learning Outcomes

- Study the mechanics of solid–liquid separation

- Understand the impact of pressure and media type

- Evaluate efficiency and product quality

- Apply filtration principles to chemical and environmental processes

Pignat Reaction Training Units for Education

Hands-On Training in Chemical Kinetics

Reaction engineering is the foundation of chemical process design. Pignat’s reaction training systems enable students to explore kinetics, reactor operation, and process optimization in a controlled lab setting.

These systems reinforce critical concepts in chemical engineering, preparing learners to design and scale up industrial processes effectively.

Key Learning Outcomes

- Understand chemical kinetics and reaction rates

- Explore different reactor designs and configurations

- Study process optimization and operating parameters

- Apply reaction engineering concepts to industrial challenges

Amatrol T7022 EV-Battery Technology Fundamentals Learning System

The Amatrol T7022 EV-Battery Technology Fundamentals Learning System provides a comprehensive introduction to electric vehicle battery systems, combining theory with hands-on practice. Learners gain real-world experience in safety, diagnostics, charging, and storage through interactive training modules designed for workforce readiness.

Hands-On Training with Real Components

This training workstation features authentic EV battery system components, including lithium-ion batteries, a smart charger/discharger, an individual cell charger, battery storage unit, electrical circuit devices, and a thermal camera. These tools ensure students practice with the same technologies used in industry settings.

Skills Covered

- Introduction to electric vehicle systems

- Basic circuit concepts: voltage, current, and resistance

- Circuit protection methods

- Lithium-ion battery characteristics and operation

- Battery charging, handling, and storage

- Battery packs and life cycles

- Battery production and testing

- EV electrical system operation

Key Learning Features

- 29 Hands-On Skills: From cell testing to smart charging and troubleshooting.

- Multiple Power Options: Includes individual batteries, packs, and 12VDC supply.

- Safety-Focused: Battery circuit breakers, storage, and low-current lithium-ion phosphate batteries.

- Interactive Curriculum: Multimedia eLearning with 3D graphics, quizzes, and simulations.

Industry-Relevant Training

With growing demand for EV technicians, the T7022 delivers the skills employers require. By learning to operate smart chargers, analyze battery packs, and apply safety protocols, students graduate with the technical confidence to enter EV and advanced transportation careers.

Tech-Labs proudly offers Amatrol’s EV-Battery Technology Fundamentals Learning System to schools, colleges, and workforce training centers.

Contact us today to integrate EV battery training into your technical program.

Build. Code. Create. Discover. Download the 2025 Catalog

Download the latest NeuroMaker catalog to explore hands-on STEM programs that blend biomedical engineering, coding, AI, and brain–computer interface (BCI) with project-based learning.

Inside, you’ll find the NeuroMaker Hand 2.0, the BioSensor Kit, the accessible NeuroMaker BCI headband, and the exciting NeuroRacing experience—plus 100+ hours of curriculum, student projects, and professional development options. (English and Spanish resources included.)

Explore:

- NeuroMaker Hand 2.0: A programmable prosthetic hand kit derived from real prosthetics work—teaches design, assembly, and coding.

- BioSensor Kit: Plug-and-play sensors (EMG, flex, and more) to capture muscle signals, motion, temperature, and color for advanced projects.

- NeuroMaker BCI: Classroom-ready EEG headband with activities introducing neuroscience, machine learning, and signal processing.

- NeuroRacing: A brainwave-driven slot-car challenge that builds focus, engagement, and makerspace excitement.

- Curriculum & Projects: 100+ hours of interdisciplinary content, student-oriented projects, and capstone challenges.

- Professional Development: e-learning Suite/Core, live support, docs & FAQs for smooth implementation.

Why educators choose NeuroMaker

- Real-world relevance: Industry-derived activities connect prosthetics, AI, and BCI to authentic problem-solving.

- Flexible implementation: Browser-friendly tools, bilingual materials, and scaffolded lesson plans.

- Student impact: High engagement, career exploration, and 21st-century skill development.

Teach Industry 4.0—Hands-On, Bench-Top, and Cloud-Ready

Bring Industry 4.0 to your classroom—on the bench. Amatrol’s Smart Factory Tabletop Mechatronics (87-TMS) blends smart sensors, I/O-Link, cloud-based SCADA, mobile apps, and MES with traditional mechatronics equipment to deliver practical, workforce-ready training. Students learn to configure networks, acquire data in the cloud, troubleshoot PLCs with electronically inserted faults, and analyze performance—skills aligned to today’s Smart Factory jobs.

The 87-TMS is part of Amatrol’s Industry 4.0 Fundamentals (I4F) multi-course program (Introduction to Mechatronics, Industrial Control Systems, Robot Operations & Programming, and Industrial Internet of Things), making it a flexible fit for high school, college, and workforce programs.

Key Learning Outcomes

- Industrial Networks & Ethernet IP addressing; managed switch diagnostics and performance tuning.

- Smart sensors via I/O-Link, including photoelectric and pressure/vacuum sensors.

- Barcode and RFID operation, programming, and Ethernet-to-serial integration.

- Cloud-based data acquisition and SCADA operations with mobile app visualization.

- Manufacturing Execution (MES): order entry, scheduling, status, statistics, and alarms.

- PLC operations and troubleshooting, including FaultPro electronically inserted faults on an Allen-Bradley L16 processor.

What’s Included

- Tabletop Mechatronics with conveyor, smart sensors, RFID, barcode reader, and I/O-Link master.

- Network hardware: 24-port unmanaged and 8-port managed Ethernet switches.

- Cloud-hosted SCADA and visual communications software (with mobile app).

- Allen-Bradley L16 controller, I/O-Link interface for system status, and FaultPro for PLC troubleshooting.

- World-class interactive multimedia eLearning with 3D animations and assessments.

Optional FANUC Robot Integration

Expand your Smart Factory Tabletop Mechatronics with a choice of industrial or collaborative robots from FANUC. Both options provide hands-on, industry-relevant automation training when combined with Amatrol’s 87-TMS stations.

FANUC 200iD Industrial Robot

Add a FANUC LR Mate 200iD six-axis industrial robot for traditional fenced-cell integration and advanced

robot programming exposure. Ideal for learners progressing into high-throughput or manufacturing-line applications.

Prerequisite: Students should have prior FANUC programming experience.

FANUC CRX-5iA Collaborative Robot (COBOT)

Available exclusively to secondary and post-secondary educational institutions, the CRX-5iA Robot with Tabletop Mechatronics Workstation enables fenceless, collaborative training that’s classroom-friendly and fast to deploy.

Training Highlights

- Fenceless robot operation with built-in force sensing for safe collaboration.

- Tablet-based programming for intuitive student interaction.

- Hands-on applications in pick-and-place, part transfer, and inspection.

- Optional iRVision for part identification and quality analysis.

Curriculum Topics Snapshot

- Industrial Networks: Ethernet/IP addresses, managed switch setup & diagnostics, performance.

- Identification & Tracking: Barcode operation/programming, RFID programming and operation.

- Smart Sensing: Photoelectric and pressure/vacuum sensors via I/O-Link.

- Cloud & SCADA: Configuring cloud-based SCADA and maintenance management.

- MES: Order entry, scheduling, status dashboards, production statistics, alarms.

- PLC & Troubleshooting: Controller operation, I/O testing, event sequencing, processor troubleshooting.

Who It’s For

Programs building pathways in advanced manufacturing, mechatronics, IIoT, and smart maintenance—including high school career academies, community colleges, universities, and incumbent-worker upskilling.

Expand with I4F Learning Systems

Pair 87-TMS with complementary learning systems such as Portable AC/DC Electrical (990-ACDC1), Electrical Control (990-EC1), Pneumatics (990-PN1), Hydraulics (990-BH1), Electronic Sensors (990-SN1), Robotics 1 & 2 (96-ROB1 & 96-ROB2), CNC Machines (96-CNC1), Skill Boss Manufacturing (95-MSB1), and Measurement Tools (990-MES1) to build a complete Industry 4.0 pathway.

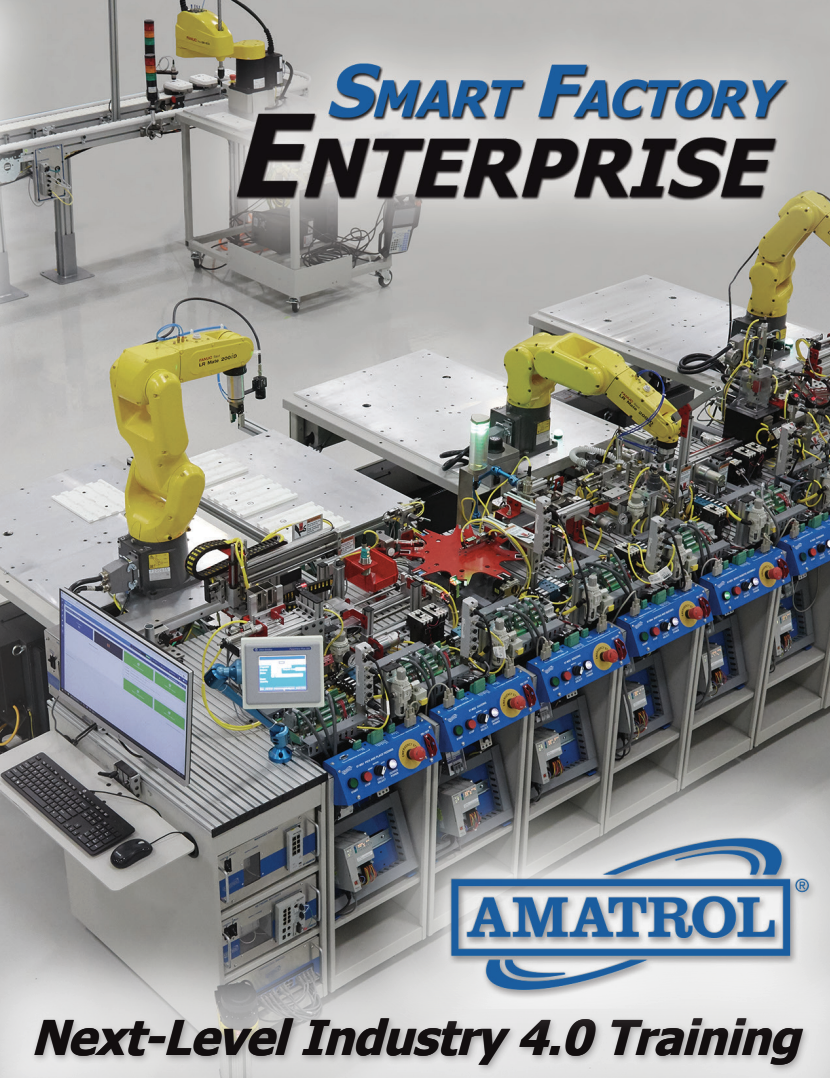

Enterprise-Level Industry 4.0 Training for the Connected Workforce

Take Industry 4.0 training to the enterprise level. Amatrol’s Smart Factory Enterprise System integrates industrial robots, conveyors, autonomous mobile robots (AMRs), machining centers, and smart sensors into a fully connected manufacturing environment. Students gain hands-on experience with secure networks, cloud-based data analytics, MES software, and IIoT communications — the technologies powering modern smart factories.

Learners explore big data analytics, predictive maintenance, and system-wide monitoring using real industrial hardware and software. The result: workforce-ready skills in networking, automation, cybersecurity, and data-driven production management.

Key Learning Outcomes

- Secure network communications, Ethernet/IP setup, and wireless integration.

- Big Data acquisition, visualization, and cloud-based MES analytics.

- Smart maintenance and production management using real-time dashboards.

- Enterprise-level system diagnostics, OEE calculations, and production tracking.

- Mobile app monitoring for system status, alarms, and maintenance alerts.

Integrated Systems & Technologies

- Smart Sensors & Product ID: RFID, barcode, analog position, and photoelectric sensors.

- Visual Communications & SCADA: Cloud-based monitoring, mobile notifications, and collaboration tools.

- Smart Conveyor System: Material handling, machine loading, and product transfer with pallet tracking.

- Smart Robot Workstations: FANUC industrial robots with laser scanners, vision guidance, and discrete I/O controls.

- Autonomous Mobile Robot (AMR): Internal transportation between manufacturing & assembly systems.

- Machining Center: CNC mill and simulator integrated via Ethernet & network security switches.

Data Analytics & Communications

Students learn to manage real-time manufacturing and maintenance data across connected systems. Industry-relevant software provides secure access to production trends, quality data, OEE, and system health, enabling proactive, data-driven decision-making.

Integration & Flexibility

Each workstation is modular and interoperable, allowing programs to start small and scale up to a full enterprise environment. Systems can be combined or used independently for focused training in sensors, robotics, machining, or networked automation.

Expand Your Smart Factory Program

Combine the Enterprise System with Amatrol’s Smart Factory Tabletop Mechatronics (87-TMS) or Smart Factory Enterprise Upgrade options for a comprehensive Industry 4.0 pathway from classroom fundamentals to enterprise-scale automation.