Amatrol's Residential Heat Pump Troubleshooting Learning System (T7100) is a comprehensive educational tool designed to impart essential HVAC/R skills to aspiring technicians specializing in residential heating, ventilation, and air conditioning (HVAC) systems that incorporate heat pumps and traditional ducting. This hands-on training program equips students with practical experience using actual equipment, such as heat pump condensers, air handlers, Wi-Fi-enabled thermostats, fuse boxes, ducting, and manifold components.

Complementing the hands-on aspect is Amatrol's interactive multimedia eLearning curriculum, which covers a wide array of fundamental topics related to residential heat pumps. These topics include thermostat operation, pressure and temperature measurements, component testing, and system troubleshooting.

The T7100 learning system offers a unique opportunity for students to engage with real-world HVAC/R equipment, featuring transparent housings, pipes, and ducting with LED illumination for enhanced understanding. Moreover, it incorporates FaultPro, Amatrol's exclusive electronic fault insertion system, enabling learners to simulate over 25 mechanical and electrical faults. This facilitates realistic troubleshooting scenarios, fostering critical problem-solving skills in a safe and controlled environment.

The interactive multimedia curriculum augments the hands-on experience with engaging 3D graphics, videos, voiceovers, quizzes, and exercises, catering to diverse learning styles. It covers crucial aspects of residential heat pump systems, such as electronic thermostat operation, pressure and temperature measurements, component testing, and troubleshooting.

Ultimately, this program equips students with the knowledge and hands-on skills required to operate heat pumps effectively, measure thermal system pressures with gauge manifolds, determine system charging using subcooling methods, test thermostatic expansion valves, and troubleshoot cooling deficiencies. Additionally, a Student Reference Guide, derived from the curriculum, provides a valuable reference tool for learners as they progress in their HVAC/R careers.

Amatrol's Environmental Applications Learning System (T7083) is an educational module designed to complement the Air Conditioning / Heat Pump Operations Learning System (T7082) or the Air Conditioning / Heat Pump Troubleshooting Learning System (T7082A). It consists of a model house with insulation, siding, shingles, and a window. Learners use digital thermometers connected to temperature probes to understand how these elements influence a home's temperature. Components like ceiling fans, attic exhaust fans, attic vents, and window tint allow students to manipulate temperature and explore concepts like heat loads, insulation effectiveness, humidity, air movement, heat transfer, psychometrics, and heat pump sizing.

When integrated with an Air Conditioning / Heat Pump system via ducts, learners can measure and adjust the home's temperature, offering a unique HVAC and home construction learning experience.

The Environmental Applications system simulates environmental variables using heaters, humidifiers, and lights to teach temperature control skills and psychrometric chart plotting. It enables simultaneous monitoring of temperature levels at different house locations, including the floor, mid-room, ceiling, inner wall, and attic, with pre-mounted sensors connected to digital outputs for data accuracy.

This system also incorporates power switches for attic fans, ceiling fans, and attic heaters, allowing learners to practice airflow manipulation and assess attic conditioners' impact on thermal systems.

Amatrol's comprehensive curriculum covers thermal system performance, heat loads, insulation effectiveness, humidification, air handling systems, and heat pump sizing. It employs interactive multimedia, including text, audio, and 3D animations. Learners gain practical skills such as load estimation and heat pump system sizing.

The package includes a Thermal Systems 2 Student Reference Guide for further reference, consolidating technical content from the curriculum into a convenient booklet. This serves as a valuable resource for learners throughout their training.

General Motors faced a challenge with heavy steel "risers" on an overhead conveyor system, hampering efficiency. Rather than choosing aluminum, they innovatively opted for 3D-printed nylon polymer with carbon fiber reinforcement, reducing weight by 32% and cutting lead time by 75%. This shift from traditional metal to polymer in 3D printing aligns with a growing trend in the automotive industry.

Additive Manufacturing (AM) offers diverse advantages for autos. To maximize its potential, choosing the right AM technology is crucial. Our companion Solution Guide, "How to Choose the Right 3D Printing Technology for Automotive Manufacturing," delves into this topic. When it comes to materials, polymer 3D printing stands out, offering:

- Fewer resource constraints

- Accessibility and ease of use

- A wide range of materials at various price points

- Lightweight yet strong alternatives to metal

We understand that the abundance of polymer options can be daunting. That's why our Solution Guide is here to help. It highlights suitable Stratasys AM technologies and materials for different automotive production phases, including Product Development, Production Support, and Part Production. Got questions? Feel free to reach out!

Introducing the latest addition from Creaform: the HandySCAN 3D MAX Series tailored for large parts. These ergonomic, industrial 3D scanners are part of the handheld MAX Series, proudly designed and produced in Canada. The HandySCAN 3D MAX Series brings forth an expansive 3D scanning area, spanning approximately 1m x 1m, precisely engineered to capture accurate 3D measurements of intricate and sizable surfaces.

This portable 3D scanner comes equipped with various scanning modes, allowing users to select the fastest scanning option for efficiency or maximum resolution for precision. This versatility empowers professionals to take optimal measurements of large components and assemblies covering up to 15 meters in scope.

Moreover, the HandySCAN 3D MAX Series boasts an array of remarkable features:

- Flex Volume: This feature empowers users to perform high-quality scans at a close range while swiftly measuring large parts from a considerable standoff distance.

- Smart Surface Algorithm: Leveraging advanced image processing, this algorithm delivers improved performance and enhances readings, particularly on challenging and contrast-rich surfaces. By harnessing the capabilities of artificial intelligence, it provides unparalleled tracking and ensures a flawless scanning process.

- Real-Time Calibration: The MAX Series seamlessly incorporates the calibration step into the scanning workflow, performing it automatically and in real time for a hassle-free experience.

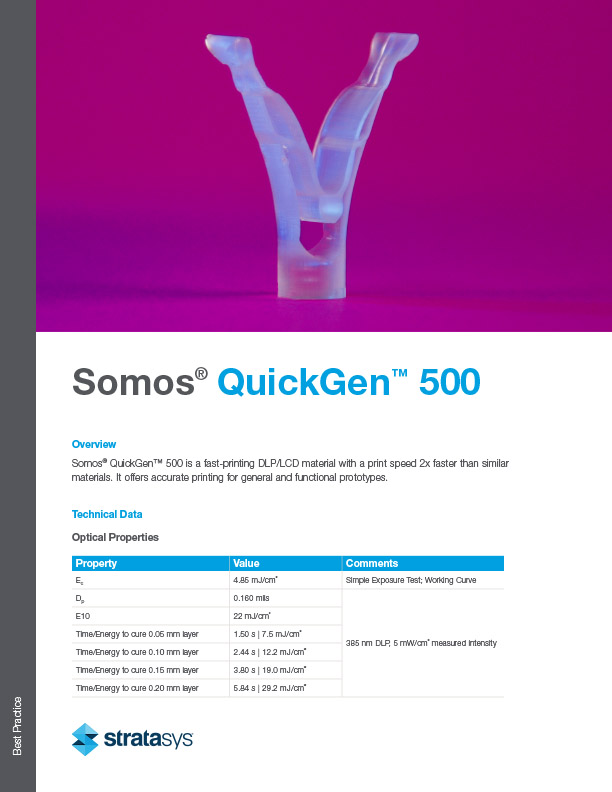

Somos® QuickGen™ 500 is a fast-printing DLP/LCD material with a print speed 2x faster than similar materials. It offers accurate printing for general and functional prototypes.

Somos® QuickGen 500 is a fast-printing, general-purpose resin for digital light processing 3D printing.

- Best option for prototyping using a flexible material

- Prints fast and accurately

Digital light processing (DLP) 3D printing technology generally boasts faster print speeds and lower capital investment. Combined with Somos® QuickGen 500, companies looking to manufacture locally can more quickly and easily adopt 3D printing.

Somos® QuickGen 500 is a fast-print-ing DLP material with a print speed 2x faster than similar materials. It offers accurate printing for general and functional prototypes.

Somos® QuickGen 500 has unique flexibility; it is more flexible than other resins, but stiffer than elastomers, offering both flexibility and spring back. The material has substantial elongation and a lower modulus with no significant strain rate dependence on elongation at break. This results in consistent performance independent of how quickly force or strain are applied. Many flexible materials show greater influence from the rate of applied force.

Key Benefits

- Fast printing

- Economical

- Balance of flexibility and stiffness

- Accurate

- Near colorless

Applications

- General and functional prototypes

- Semi-flexible applications

- Applications with detailed features

- Fluid flow analysis

High-temperature photopolymer with good strength for functional parts, from Evonik INFINAM®.

Our first photopolymer from Evonik is a strong, heat-resistant material that addresses applications where a combination of high-temperature resistance and good elongation at break are crucial. P3 Deflect 120 has low viscosity and high green strength, which make it suitable for parts with challenging geometries such as wiring housings, connectors, or mold tooling.

Key Benefits

- High HDT, 121°C (250°F) with good elongation at break

- Very stiff and high green strength

- Easy to print + single component material

- Color: Black

Developed on and certified for the Origin® One 3D printers

DURA56 is a tough, high-impact photopolymer with excellent surface quality. For functional end-use parts and prototypes.

Created by Stratasys and LOCTITE to address end-use and prototyping applications with high material consumption. Ideal for housings, parts with mating features, or class A surfaces.

Benefits:

- High-impact strength

- Tough

- Excellent surface finish

- Low part cost

- Low Viscosity

Ideal for:

- Enclosures and Housings

- Jigs & Fixtures

- Functional testing

High Rebound Photoelastic Black

P3 Stretch IND475TM is a single-component UV resin that, when cured, transforms into a soft and flexible elastomeric material. This material offers a well-balanced combination of hardness, strength, and elongation, making it versatile for various applications.

Additionally, IND475 is a low-viscosity liquid that can be easily 3D printed at room temperature.

Benefits:

- True elastomeric behavior

- Fast Printing with low shrinkage behavior

- High resilience / High energy return

Ideal for:

- Air and dust gaskets

- Flexible seals and housings

- Cushioning pads

Enabling Advanced 3D Printing Solutions

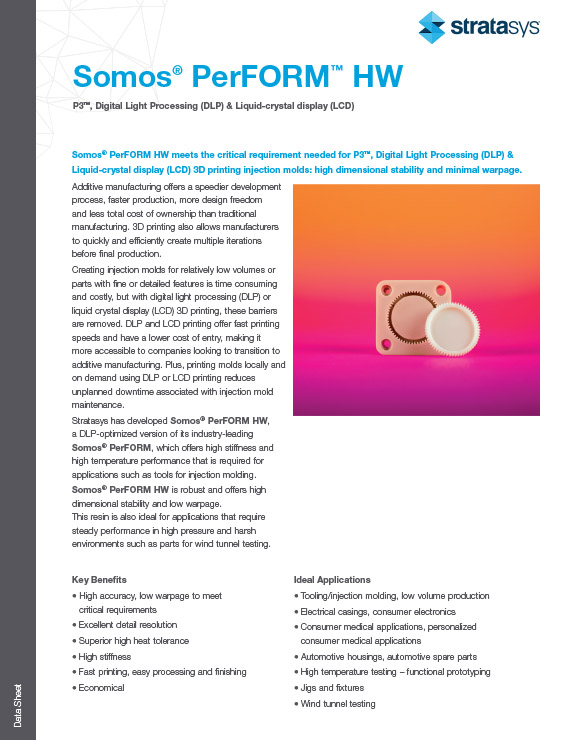

Somos® PerFORM HW is tailored for P3TM, Digital Light Processing (DLP), and Liquid-crystal display (LCD) 3D printing technologies, catering to the specific needs of injection mold development. This cutting-edge material offers exceptional dimensional stability and minimizes warpage, crucial for precision and quality.

3D printing with Somos® PerFORM HW provides a host of advantages over traditional manufacturing methods. It accelerates development processes, speeds up production, unlocks design creativity, and lowers the total cost of ownership. Manufacturers can swiftly iterate designs before final production, reducing time and cost.

Creating injection molds, especially for low-volume or intricately detailed parts, has historically been time-consuming and expensive. However, DLP and LCD 3D printing eliminate these barriers. These technologies offer rapid printing speeds, with a lower entry cost, making additive manufacturing accessible to transitioning companies. Additionally, on-demand local production with DLP or LCD printing reduces unplanned downtime associated with mold maintenance.

Stratasys presents Somos® PerFORM HW, an optimized version of the renowned Somos® PerFORM, finely tuned for DLP technology. This resin excels in stiffness and high-temperature performance, making it ideal for applications like injection molding tools. It boasts robustness, dimensional stability, and minimal warpage, ensuring consistent performance in high-pressure and demanding environments, such as wind tunnel testing.

Key Benefits

- High accuracy with minimal warpage, meeting critical requirements

- Outstanding detail resolution

- Exceptional high-temperature tolerance

- Superior stiffness

- Fast printing, ease of processing, and efficient finishing

- Cost-effective solution

Ideal Applications

- Tooling and injection molding, suited for low-volume production

- Electrical casings and consumer electronics

- Customized consumer medical applications

- Automotive housings and spare parts

- High-temperature testing and functional prototyping

- Jigs and fixtures

- Wind tunnel testing

Somos® PerFORM HW is your gateway to innovation, offering advanced 3D printing solutions with exceptional performance and reliability.