Amatrol's 87-SWPF1V Smart Robot Logistics Palletizing Workcell teaches trainees how to operate, program, maintain, and troubleshoot a robotic palletizing workcell. Students will gain hands-on practice on how to power up and jog an industrial robot workcell using an HMI, operate the workcell both manually and automatically, enter and interpret commands, configure robot vision settings, track robot performance, and ensure safety devices are functioning correctly.

In this video, Regional Manager Jason Everett provides an overview of Amatrol’s Smart Controls Troubleshooting Workstation, including its operation and primary features.

Amatrol’s Smart Controls Troubleshooting Workstation teaches users the hands-on programmable logic controller (PLC) troubleshooting skills they need to excel in today’s jobs that feature various applications with Industry 4.0 technologies.

The Smart Controls Troubleshooting Workstation (Model 895) by Amatrol is an essential educational tool designed for educators. This hands-on learning system is tailored to equip users with advanced programmable logic controller (PLC) troubleshooting skills, preparing them for a wide range of modern job opportunities in the era of Industry 4.0 technologies.

With this workstation, users gain practical experience in operating, programming, and troubleshooting PLCs interfacing with diverse applications. These applications encompass electro-pneumatics, motor control, temperature control, variable frequency drives, smart sensors, process control, and I/O Link communications.

This comprehensive tabletop system immerses students in real-world scenarios, featuring three different types of robust Allen-Bradley PLCs (ControlLogix, CompactLogix Modular, and CompactLogix), distributed I/O via Ethernet/IP communications using industrial managed switches, smart sensors, smart motor drives, intelligent interface terminals, wireless Ethernet communications, and process control applications.

By engaging with industry-relevant applications and hands-on exercises, students develop a strong foundation for successful careers across various industries that leverage advanced Industry 4.0 smart control technologies. This versatile learning system empowers educators to prepare their students for the demands of today's technology-driven job landscape.

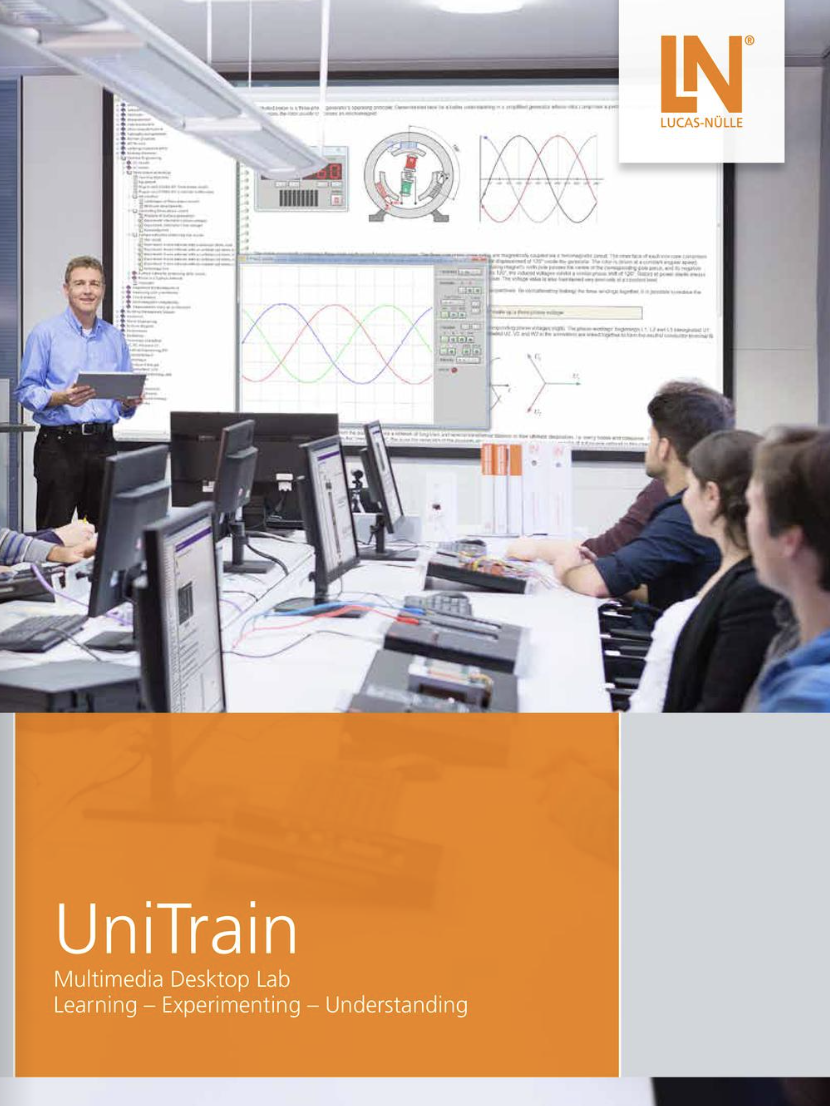

Lucas-Nuelle's Unitrain is a comprehensive and versatile training system designed to empower learners in various technical fields. This innovative educational solution encompasses various disciplines, including electronics, automation, telecommunications, and more.

Unitrain stands out for its hands-on approach, allowing students to gain practical experience and in-depth knowledge through real-world simulations and experiments. It features a user-friendly interface that facilitates interactive learning, enabling students to grasp complex concepts and theories easily.

One of the key advantages of Unitrain is its adaptability to different learning environments, from traditional classrooms to remote and online settings. This flexibility ensures that learners can access high-quality educational content wherever they are.

With Lucas-Nuelle's Unitrain, students can explore various topics, from basic electronics principles to advanced automation and control systems. This comprehensive training system equips learners with the skills and expertise needed to excel in today's competitive technical landscape, making it an invaluable resource for educators and students.

Amatrol eLearning: Revolutionizing Skills Development

Amatrol eLearning is a pioneering platform that has transformed the landscape of technical and vocational education. With a rich history dating back to 1981, Amatrol has continually evolved its training solutions to meet the ever-changing needs of industries worldwide. The advent of eLearning has allowed Amatrol to take its commitment to excellence in education to a new level.

Amatrol eLearning is designed to provide learners with hands-on, interactive training experiences in critical areas such as industrial automation, manufacturing, and STEM (Science, Technology, Engineering, and Mathematics). Here's a closer look at what sets Amatrol eLearning apart:

1. Comprehensive Curriculum: Amatrol offers a vast library of courses that cover a wide spectrum of topics, from basic technical skills to advanced industrial automation. The curriculum is meticulously developed to align with industry standards and best practices.

2. Engaging Content: The platform leverages multimedia, including interactive simulations, videos, animations, and quizzes, to create an engaging learning experience. Learners can practice real-world tasks in a virtual environment, enhancing their understanding and retention of key concepts.

3. Flexibility: Amatrol eLearning is accessible anytime, anywhere, making it ideal for both individuals and organizations. Learners can study at their own pace, which is particularly valuable for those juggling work, family, and education.

4. Scalability: It's suitable for a diverse audience, from high school students and entry-level technicians to seasoned professionals seeking to upskill or reskill. Companies can also implement Amatrol eLearning to train their workforce efficiently.

5. Measurable Results: The platform allows for progress tracking and assessment, enabling learners and educators to monitor performance and make data-driven decisions for improvement.

6. Industry Partnerships: Amatrol collaborates with industry leaders to ensure that its content remains up-to-date and relevant to the demands of the job market.

Amatrol eLearning represents a paradigm shift in technical education. It equips learners with practical skills and knowledge, preparing them to excel in today's fast-paced, technology-driven industries. Whether you're an educator training tomorrow's workforce or an organization striving for a skilled workforce, Amatrol eLearning is a powerful tool for success.

Amatrol's Basic Refrigeration training system, the T7045, revolutionizes HVAC/R education with its hands-on approach to learning the intricacies of working refrigeration systems. This compact tabletop unit is a cornerstone of HVAC/R training, imparting essential skills applicable in diverse industrial, residential, and commercial settings, ensuring learners are well-prepared for the ever-expanding HVAC/R industry.

To maximize the benefits of the T7045, a sturdy table is recommended, such as Amatrol's 82-610 Mobile Technology Workstation, capable of supporting the system's weight. As part of Amatrol's comprehensive HVAC training offering, this basic refrigeration training system is a valuable addition.

The T7045 curriculum encompasses many critical topics, including refrigeration systems, temperature and pressure management, enthalpy, the combined gas law, and more. Learners gain practical experience with industry-standard components, such as hermetic compressors, temperature and pressure gauges, evaporators, and condensers. This hands-on training equips them with the skills to operate, monitor, and adjust refrigeration systems commonly encountered in the field.

Key components featured in the T7045 mirror those found in real-world HVAC/R systems, including R134a Refrigerant, evaporator and condenser coils, variable speed fan controls, a hermetic compressor, pressure and temperature gauges, and a dual high-pressure cutout switch. These elements facilitate hands-on skill-building exercises like setting pressures on a dual-pressure control device, using gauge manifolds, and mastering basic mechanical refrigeration techniques.

The T7045 comes with a comprehensive refrigeration and cooling curriculum that delves into filters/dryers, moisture indicators, dual-pressure devices, refrigerants, and more. Concepts like using sight glass/moisture indicators, testing automatic expansion valves, and understanding mass flow rates are thoroughly covered. Additionally, this course is available in an online eBook format, offering learners convenient access to course content.

For reference and continued learning, a Student Reference Guide is included with the system, offering a condensed, cost-effective reference tool that proves invaluable after training completion.

In summary, Amatrol's T7045 Basic Refrigeration training system empowers HVAC/R enthusiasts and professionals with hands-on skills that align with industry demands. Its real-world components, in-depth curriculum, and comprehensive resources make it an indispensable asset for anyone looking to excel in the HVAC/R field.

Amatrol's Air Conditioning / Heat Pump Troubleshooting Learning System (T7082A) is an essential HVAC training tool that imparts hands-on troubleshooting skills for heat pumps, air conditioning, and refrigeration systems. It integrates FaultPro, an electronic troubleshooting system unique to the industry, enabling learners to identify faults like blockages, leaks, and refrigerant issues. This training is invaluable for HVAC technicians.

The T7082A comprises a comprehensive set of components, including a mobile workstation, compressor, pressure control system, refrigeration circuit, instrumentation set, temperature control system, and more. These elements provide practical experience in operating, adjusting, and troubleshooting real-world air conditioning and heat pump systems.

Learners delve into crucial topics like compressors, condensers, metering devices, evaporators, and temperature and pressure control devices. Amatrol's FaultPro system enables learners to insert and troubleshoot faults as part of their training, with instructors having the ability to set faults for testing and tracking progress. With twenty-four faults covering areas such as electrical, refrigerant flow, and component adjustment, learners gain expertise in troubleshooting issues like blockages, blower problems, insufficient heating, and system cut-outs.

The T7082A features a wide array of industrial components, including flow meters, expansion valves, pressure/temperature gauges, and reversing valves. Learners engage in hands-on skill-building tasks, such as measuring subcooling in a mechanical refrigeration system, setting pressures on dual-pressure control devices, using gauge manifolds to measure thermal system pressure, testing thermostatic expansion valves, and assessing compressors.

In summary, the Amatrol T7082A equips HVAC learners with practical troubleshooting skills, using real-world components and advanced technology like FaultPro. It's a comprehensive, hands-on training system that prepares technicians for the complexities of HVAC systems in industrial, commercial, and residential settings.

Amatrol's T7082A is a hands-on HVAC training system, incorporating FaultPro for troubleshooting practice. It covers real-world air conditioning and heat pump systems, offering comprehensive learning in components and fault identification. Ideal for HVAC technician training.

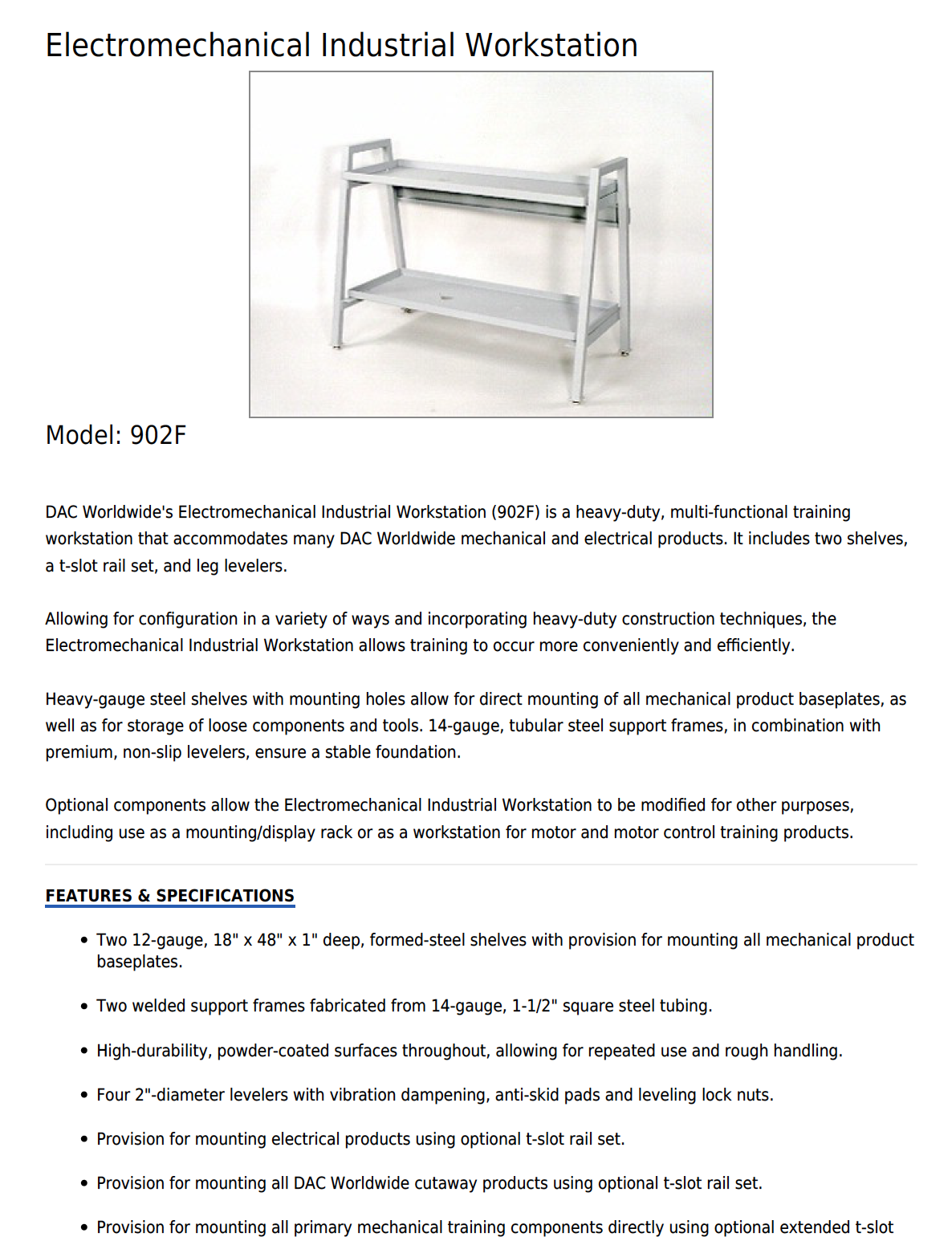

DAC Worldwide's Electromechanical Industrial Workstation (902F) is a robust, versatile training platform designed to accommodate a range of mechanical and electrical products. Featuring two shelves, a t-slot rail set, and leg levelers, it offers flexible configurations for efficient training. Heavy-gauge steel shelves with mounting holes enable direct attachment of mechanical product baseplates and storage for tools and components. Its 14-gauge tubular steel support frames, combined with non-slip levelers, ensure stability. This workstation can be customized with optional components for various purposes, such as a mounting/display rack or a workstation for motor and motor control training products. It's a durable, adaptable solution for hands-on industrial training.

DAC Worldwide's Hermetic Compressor Cutaway (373-110) is an invaluable training tool, meticulously dissecting a fractional-horsepower refrigeration compressor. With both the steel shell and compressor cutaway, learners gain complete visibility into its operating components. Painted cutaway surfaces enhance component geometry, revealing internal designs.

This cutaway serves as a comprehensive resource for HVAC training, offering insights into compressor design, maintenance, troubleshooting, and preventive measures. Learners explore real-world applications, making it suitable for both educational and industrial settings.

Mounted on a modular display panel, it's adaptable for various display fixtures and storage structures. The removable, individually-mounted cutaway areas provide convenient classroom use and support visual learning.

Durability is ensured with high-endurance urethane coating and color-coded component parts, making it resistant to frequent handling and enhancing the learning experience. This teaching aid enhances both instructor-led training and independent student exploration in air conditioning and refrigeration programs.

In summary, DAC Worldwide's Hermetic Compressor Cutaway is a versatile, hands-on tool that facilitates in-depth understanding of compressor systems, making it an invaluable asset for HVAC training and education.

Amatrol's Advanced Manufacturing program presents an innovative approach that seamlessly integrates practical, hands-on skills with a robust curriculum to deliver an exceptional learning journey. This comprehensive training program comprises various proficiency levels, commencing with fundamental concepts and progressively advancing to more complex technological applications. With a presence in over 3,500 installations worldwide and a continuous expansion, Amatrol reaffirms its unwavering dedication to addressing the technical skill shortages in our workforce.

- Highly Demanded Industry Skills: Hands-On and Job Ready

- Individualized Self-Paced or Group Learning Flexibility

- Extensive Curriculum Spanning Basics through Advanced

- Authentic Industrial Troubleshooting

- Durable, Industrial Equipment Designed for Effective Teaching

- Superiour Multimedia Interactivity Connects with Learners

- eAssessment to Accelerate Learning, Improve Effectiveness

- Learning Anywhere, Anytime — 24/7

- Outstanding Support

Pages

-

The AD Access combines economic ownership with performance to match the small laser user. A three-stage filter condition indicator is included as a standard feature, together with three stage filtration: DeepPleat pre-filter, HEPA and chemical section.

-

The Advantage Base 1 Oracle has been designed so that a number of manufacturer’s laser engravers can sit on top of the extractor, effectively doubling it up as a workstation.

All the Base units in the range have the option of an onboard compressor for a compact installation. BOFA’s ‘Easi-Seal’ filter location makes filter change easy, quick and safe.

The revolutionary Auto-Voltage Sensing Turbine automatically self-adjusts to run on any voltage worldwide, whilst the Reverse Flow filter technology enhances filter performance and ensures longer filter life.

-

The Laser Companion 'Ride On' range has been designed so that a number of manufacturer's laser engravers can sit on top of the extractor, effectively doubling it up as a workstation.

The Advantage Base 2 Oracle has been designed so that a number of laser engravers can sit on top of the extractor, effectively doubling it up as a workstation.

All the Base units in the range have the option of an onboard compressor for a compact installation. BOFA’s Easi-Glide filter location mechanism makes filter changes easy, quick and safe.

-

The Advantage Base 3 has been designed specifically for the Universal VersaLaser engraver. The dimensions of the unit allow the VersaLaser to fit perfectly onto the extractor, effectively doubling it up as a workstation. The unit is also offered with an onboard air compressor to provide the laser with its air assist requirements and comes complete with extraction hose kit and compressor link up on compressor models.

-

The Advantage Base Z has been designed specifically for the new Epilog Zing laser engraver. The dimensions of the unit allow the Zing to fit perfectly onto the extractor.

-

The AD GoldSEAL RS is a dust extraction system designed for the jewelry industry that recovers and collects precious metals.

The metal particles are collected in an easy to remove tray and the HEPA filter can be incinerated to reveal the precious metal collected in the filtration process.

Automatic Flow Control allows the user to preset correct air flow rates, for lower noise levels and allow further protection of the HEPA filter.

-

The AD Universal fume extraction and filtration system has been designed to provide cost-effective solutions for light to medium duty applications. These compact systems are ideal for small-scale industrial environments and light laser coding applications.

-

High school students are destined to become knowledge workers, regardless of whatever specific career choice they make. Engineering and technology offer some of the most rewarding career opportunities possible! Amatrol’s high school programs are designed to engage students who demand a high degree of interactivity and challenge to keep them interested and learning. All of our high school programs articulate to colleges for up to 18 credit hours.

-

Item Number:890-PEC-BThe model 890-PEC-B Programmable Controller Troubleshooting Learning System teaches programming and troubleshooting of programmable controllers and their use in industrial, commercial, and residential applications. The 890-PEC-B System teaches PLC troubleshooting like no other product by providing a hands-on learning station that models real world PLC-controlled machines with up to 40 faults that can be inserted into the system.

-

Amatrol’s fluid power training systems are the best in the industry. Our learning programs are developed in partnership with industry and education to ensure that the skills are on target to support modern industry needs.