At Tech-Labs, our approach goes far beyond the sale of equipment. For over 50 years, we have partnered with educators and trainers to ensure they receive the support they need long after installation. We believe in lifelong partnerships, which is why we provide full-circle services, from initial site prep to ongoing training for new instructors.

Our team, including Mark Venske, Director of Technical Services, and Ross Patton, Inside Sales Manager, is dedicated to customer success. Whether it’s through technical orientation, ongoing troubleshooting, or on-site retraining, we ensure that the tools we provide are fully utilized to impact lives and careers positively.

Our commitment is simple: if we’re only meeting your expectations, we’re not doing enough. We strive to exceed what you expect from any other company, offering unmatched support and guidance throughout your entire journey with us.

Explore how our solutions can enhance your programs by contacting us today. Together, we’ll make sure the next generation of learners is equipped to succeed.

Reach out to our team today to learn more about how we can support your training goals. Contact Us

Tech-Labs, in partnership with TacMed, offers a range of advanced simulators to equip medical professionals, first responders, and healthcare educators with realistic training tools. These simulators provide hands-on experiences in managing traumatic situations, helping students and trainees develop critical skills in a controlled environment.

The TacMed Clinical Response Upper-Resuscitate and Lower Simulators are designed to offer comprehensive training in airway management, neurological assessment, bleeding control, and more. With options for four upper torso and six lower torso configurations, educators can tailor training sessions to match specific clinical skill sets.

Whether it’s performing tracheostomies, decompressing a tension pneumothorax, or managing a gunshot wound, TacMed simulators give learners a life-like experience. These simulators also feature vital signs monitoring, realistic limb movements, and pulse detection to mimic real patient responses.

At Tech-Labs, we ensure that implementing these simulators into your program is seamless. We provide on-site training to faculty, ensuring that educators are fully prepared to use the equipment effectively.

Contact us today to learn how TacMed simulators can elevate your medical training program.

Learn more about TacMed's trauma simulators and schedule a demonstration with our team. Contact Us

At the University of Texas at Arlington Research Institute (UTARI), 3D printing plays a pivotal role in driving medical research forward. With the help of Tech-Labs and cutting-edge Stratasys printers like the Neo450s SLA and J35 PolyJet, UTARI’s researchers are able to quickly prototype and fabricate parts with unmatched precision.

Research Scientist Alex Jamison, part of the Biomedical Technologies division, highlights their work in creating soft robotic exoskeletons to aid patients with neurological conditions. Using advanced 3D modeling and simulation, their team designs wearable devices that help patients regain function in their hands and wrists. The flexibility and speed of 3D printing have significantly improved their ability to iterate on designs and produce exact replicas of their simulations.

Clayton Webb, Equipment Technician at UTARI, emphasizes how 3D printing has transformed their workflow. What once took days to create using traditional CNC methods now takes only hours with the Neo450s. With the ability to switch between different materials, the team can quickly adapt to new projects and challenges.

Through their partnership with Tech-Labs, UTARI continues to innovate, creating life-changing medical solutions. With ongoing support and expertise from Tech-Labs, the team is always prepared to meet the demands of their groundbreaking research.

Learn more about how Tech-Labs and Stratasys 3D printing solutions can accelerate your research. Contact Us

At Tech-Labs and X-Cal, we are more than just a distributor – we are your partner in transforming education and workforce development. For over 40 years, we’ve provided tailored technical solutions to schools, businesses, and governments, helping close the skills gap and prepare the workforce of the future. Our expertise spans a wide range of industries, from 3D printing and industrial automation to medical training and Industry 4.0 solutions.

Led by Warner Brown, CEO and President, Tech-Labs and X-Cal operates Solutions Centers in Katy, Texas, and Utah, with a new center opening soon in Denver. These centers allow us to showcase customized solutions to fit our clients' needs, providing a hands-on experience in a state-of-the-art facility. Even if you can’t visit us in person, we bring our solutions to you with our mobile equipment setups.

We partner with industry leaders like SACA, MSSC, Stratasys, and FANUC to offer nationally recognized credentials and competency-based training programs that ensure successful outcomes for both educators and industries. Whether you are looking to enhance a technical program at a school or need help with workforce development in your company, our subject matter experts will guide you every step of the way, from curriculum development to equipment adoption and training.

Our mission is to help close the skills gap by working with educators, companies, and government agencies to deliver solutions that are easy to implement and designed to succeed.

Get in touch with us to explore how we can help your organization with tailored solutions. Contact Us

The EDU MiNi MiLL: Precision CNC Training for Future Engineers

The EDU MiNi MiLL is designed specifically for educational environments, providing students with practical, hands-on experience in CNC machining and modern manufacturing. This compact yet powerful machine is built with precision engineering and an industrial-grade control system, ensuring students are trained on the same technology used in professional settings. With flexible integration into various curricula, the EDU MiNi MiLL is ideal for foundational training as well as more advanced projects, giving students the skills needed to thrive in today’s fast-evolving manufacturing industry.

In addition to its robust performance, the EDU MiNi MiLL prioritizes safety and user-friendliness, creating a secure learning environment for students of all skill levels. The intuitive interface, paired with precision servo motors, allows for highly accurate and efficient machining. Whether you're looking to expand your current technical training program or enhance research capabilities, the EDU MiNi MiLL offers the versatility and reliability you need to shape the engineers of tomorrow.

Contact us today to learn how the EDU MiNi MiLL can become a part of your educational program!

Fronius is a global leader in welding technology, renowned for its innovative solutions catering to various industries. With a focus on precision, efficiency, and quality, Fronius offers advanced welding systems that enhance productivity and ensure superior results for both manual and automated welding applications. Their products are designed to meet the rigorous demands of automotive, aerospace, and manufacturing industries, making Fronius a trusted partner for businesses looking to optimize their welding processes.

Fronius continuously pushes the boundaries of technology by integrating smart features, including digital connectivity and process monitoring, ensuring that its welding systems remain at the forefront of Industry 4.0 advancements. With a strong commitment to sustainability, Fronius also provides energy-efficient solutions that reduce operational costs and minimize environmental impact, aligning with the needs of modern industry professionals.

The Stratasys Additive Manufacturing Certification Program equips students with the skills and credentials needed to excel in modern industries that rely on 3D printing technology. Developed in collaboration with NOCTI (National Occupational Competency Testing Institute), this program offers a structured curriculum that provides hands-on experience with Stratasys 3D printers and prepares students for the NOCTI certification exam. By implementing this program, educators ensure that students graduate with valuable, industry-recognized certifications that demonstrate their proficiency in additive manufacturing.

This certification not only benefits students by boosting their employability, but also elevates the reputation of educational institutions by providing accredited, cutting-edge technical training. Schools that adopt this certification gain access to funding opportunities, potential partnerships with industry leaders, and the chance to build a center of excellence for additive manufacturing. The program is designed to align academic instruction with real-world applications, fostering student readiness for the fast-evolving manufacturing and technical sectors.

For educators, this program provides a clear path to establishing their facility as a certified Stratasys additive manufacturing site, offering a seamless transition from instruction to certification. Students gain hands-on experience with 3D printing technologies used across industries, enhancing their problem-solving skills and preparing them for critical roles in the workforce.

The second webinar in the series, titled “The Road to Certification: How to Establish a SACA Academy,” offers essential guidance for educators, administrators, and industry partners interested in launching a SACA-certified academy. By establishing a SACA Academy, educational institutions can equip students with certifications that address the skills gap in smart manufacturing and automation—fields that are increasingly vital to today’s economy.

In this session, our panelists share:

- The roadmap for setting up an academy, from initial planning to implementation

- The educational and economic benefits of offering SACA certifications

- Best practices for gaining buy-in from stakeholders

- Resources and curriculum options to support an effective program

This webinar also features a Q&A segment where participants received direct insights from Tech-Labs and SACA representatives, who address common questions and provide valuable recommendations for overcoming obstacles in program setup.

For institutions aiming to stay at the forefront of industrial training, this session is an invaluable resource for ensuring that students gain critical skills and industry-recognized credentials. This is a key opportunity to empower the workforce of the future with hands-on, certified expertise in smart automation.

<Want to bring SACA certifications to your school? Contact Tech-Labs to start planning your SACA Academy today and explore how our team can assist in establishing a robust certification program that meets industry demands.

Throughout this video, students and teachers share the meaningful impact the program has had on their lives:

- Mr. Johnson discusses Tech-Labs' support with training and equipment, which has inspired students to pursue certifications and careers in technology.

- Camden, a 15-year-old student, explains how the program has fueled his enthusiasm for robotics and technical skills, opening doors for his future career.

- Benjamin, a 10th grader, shares how his passion for technology is inspired by his father, and how he sees robotics as a way to honor his dad’s legacy.

- Valerie, also 15, speaks about her aspirations in manufacturing and robotics, inspired by her father’s work in the field.

This program provides students with technical expertise often reserved for college, giving them a significant head start in STEM fields. As Mr. Johnson notes, “I don’t teach to the current child; I teach to the future adult.” With Tech-Labs’ support, the program fosters students’ skills and confidence, setting them on a path toward success in technology and automation industries.

Discover how Mountainland Technical College (MTECH) in Utah is revolutionizing its Automation Technology program with state-of-the-art equipment and a comprehensive curriculum. Join program coordinator Jeff Erickson and instructor Kiele Lee as they share their experiences and the profound impact of using cutting-edge technology in their classrooms.

In this video, you'll learn about:

- The program uses a wide range of equipment, from pneumatics and hydraulics to advanced PLC logic controls and FANUC Robotics and mechatronics.

- The seamless integration of curriculum and hands-on training, made possible by X-CAL and Tech-Labs, ensures students acquire the essential skills needed for industry success.

- The SACA certification program validates student competencies through rigorous testing and prepares them for real-world challenges.

- Inspiring student success stories, including those who have transitioned from different backgrounds and significantly improved their career prospects.

Ready to elevate your school's technical training programs? Contact us today to learn how our training solutions can help your program achieve the same success!

Transform your curriculum and empower your students to thrive in their careers!

Pages

-

Item Number:F900The F900 gives you the ability to create large parts or multiple smaller parts in the broadest array of FDM materials. With the largest build chamber available among FDM printers, the F900 enables additive manufacturing at scale while delivering consistent, accurate results.

-

Item Number:450mc and 380mcThe Fortus 450mc can run standard, engineering, and high-performance FDM thermoplastics in a 16 x 14 x 16 in. build envelope. It features improved ease of use, including a touchscreen user interface, and builds complex parts faster than its predecessor, the 400mc.

-

Meet high production demands with the Stratasys H350 powder bed fusion 3D printer. Leveraging Selective Absorption Fusion, SAF technology, into the H-Series production platform, the Stratasys H350 is designed to deliver functional, production-grade parts with unrivaled consistency.

-

Item Number:J4100Whatever the complexity, the J4100 can handle any design. An ultra-large build tray, multi-material capabilities, fast throughput, and a wide range of material properties mean unlimited design possibilities and improved productivity.

-

Item Number:J850 Pro / J850 Prime / J826 PrimeFrom ideation to creation, the J8 Series delivers a fully-functioning, multi-material, Pantone™ validated prototype 200% faster than traditional methods.

-

The J850™ TechStyle™ 3D printer is powered by 3DFashion™ technology and provides full-color, multi-material capabilities for designs that can be printed directly to fabric, garments, footwear, and luxury accessories, delivering results that are not possible with traditional methods.

-

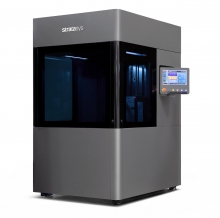

Item Number:Neo450e / Neo450sThe Stratasys Neo450e is an affordable industrial-grade 3D printer producing small to medium parts with consistent accuracy and repeatability. The Neo450s offers performance and versatility along with all the benefits of Neo450e.

-

Item Number:NEO800The open-system Stratasys Neo800 3D Printer uses Stereolithography (SL) technology to delivers high-quality parts with superior surface quality, accuracy, and detail at unprecedented speeds.

-

Objet30 Prime offers four additional materials expanding to rubber-like materials for soft-touch features, flexible components, and even bio-compatible for medical device prototyping and end-use parts such as surgical guides.