Pignat’s Multi-Purpose Reactors are modular systems that support a wide range of chemical reactions and configurations. Available in both manual and SCADA-controlled automated versions, these reactors allow for in-depth experimentation with parameters such as temperature, pressure, mixing speed, and reaction kinetics—mirroring real-world chemical production environments.

Ideal for upper-level university courses, research applications, and operator training, these versatile systems support synthesis, batch and continuous operation, and multiphase reactions. Units like the UPR/5000 combine automation, safety interlocks, and real-time data acquisition for modern chemical engineering instruction.

Pignat’s OTP Pilots simulate full-scale industrial processes, giving students and professionals a realistic, high-fidelity environment to explore advanced chemical engineering operations. These systems replicate complex processes like controlled continuous distillation, CO₂ absorption and regeneration, and distillation control using industrial-grade components and instrumentation.

Designed for universities, pilot plants, and advanced workforce development centers, OTP Pilots emphasize safety, control systems, and operational efficiency. Learners gain experience with real process variables, troubleshooting, and scalable process optimization—preparing them for roles in chemical manufacturing, environmental engineering, and process design.

Absorption processes are critical in gas-liquid operations where a component from a gas phase is transferred into a liquid solvent. Commonly used in environmental control (e.g., CO₂ capture) and chemical production, these systems help study parameters such as gas solubility, contact efficiency, and column dynamics. Educational units like Pignat’s ABS/100 and ABS/2000 provide hands-on training in both manual and automated gas absorption processes, reinforcing understanding through transparent components and real-time instrumentation.

Adsorption is a surface-based separation technique in which molecules from a fluid phase adhere to a solid surface, often used for purification, drying, and environmental applications. With units like ADM/2000 and ADS/2000, learners can explore gas-solid and liquid-solid adsorption in lab and pilot scales. These systems support detailed study of breakthrough curves, isotherms, and regeneration cycles, making them ideal for chemical engineering and process technology programs.

Crystallization is a key method for purifying solid compounds from liquids and is widely used in pharmaceuticals, food processing, and chemical manufacturing. Pignat’s CRA/100 and CRA/200 systems enable the study of both batch and continuous crystallization. These units support investigation into cooling and evaporation methods, crystal size distribution, and process optimization—ideal for demonstrating real-world industrial separation techniques in an academic setting.

Distillation is a fundamental separation technique that exploits differences in boiling points to purify or fractionate chemical mixtures. Pignat’s product line ranges from lab-scale DVI/100 and DVI/300 mini units to advanced pilot-scale DVI/6000 systems. These solutions cover essential concepts like mass and energy balances, reflux ratios, thermosiphon reboilers, and differential pressure monitoring, preparing students and professionals for real-world industrial distillation operations.

An ebulliometer is used to determine the boiling point of liquids and study vapor-liquid equilibrium, a core topic in thermodynamics. Pignat’s EEA/1000 and EEA/2000 ebulliometers allow for both manual and automated experiments, supporting instruction in azeotrope formation, Raoult’s Law, and boiling point elevation. These compact units serve as vital tools in chemical engineering labs focusing on phase equilibrium and fluid properties.

Liquid-liquid extraction is a separation method used to isolate compounds based on solubility differences in two immiscible liquids. Pignat’s ELA/100 and ELA/3000 stirred extraction units, along with the ELM/2000 mixer-settler system, allow learners to explore batch and continuous extraction processes. These systems are ideal for studying partition coefficients, emulsion formation, and separation efficiency in pharmaceutical, food, and chemical industries.

Evaporation is essential for concentrating solutions by removing solvents, typically water, through thermal energy. Pignat offers both simple (EVV/100) and multiple-effect (EVV/1000, EVV/2000) evaporators to demonstrate core concepts like heat transfer, boiling point elevation, and energy savings through effect cascading. These units are ideal for exploring process efficiencies and the design considerations found in food processing and chemical production.

Filtration is a solid-liquid separation process that is foundational in industries such as pharmaceuticals, water treatment, and chemical manufacturing. Pignat’s FSP/3000, FIL/2000, and FIP/2000 units offer varied filtration methods and study parameters such as flow rate, cake resistance, and filter media selection. These systems enhance student comprehension of industrial-scale separation challenges while maintaining hands-on laboratory relevance.

Pages

-

Doosan's DEM series is a compact vertical machining center for 3-axis general machining with high rigidity structure. This model is designed with a 22” x 16” bed which is very suitable for basic cutting processing.

-

Doosan's LEO is a small footprint 2-axis lathe with big capabilities. The LEO 1600 offers a 6” chuck and the largest machining area in its class.

-

Enhance port training with CM Labs’ Double Empty Container Handler Add-On—an exclusive simulation module for twin-lift operations, including safe container stacking, ITV trailer interaction, and obstacle navigation.

-

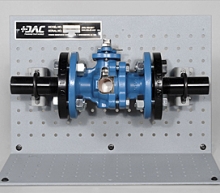

Item Number:253DDAC Worldwide's Downsized Ball Valve Cutaway (253D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in industrial ball valves' design, construction, and maintenance. Through carefully-planned sectioning and color-coding, the complete internal configuration of the valve is exposed and showcased. This tabletop sample supports training in a variety of process-related industries.

-

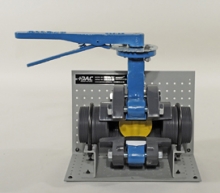

Item Number:254DDAC Worldwide's Downsized Butterfly Valve Cutaway (254D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in the design, construction, and maintenance of industrial concentric, wafer-type resilient seat butterfly valves. Through carefully-planned sectioning and color-coding, the complete internal configuration of the valve is exposed and showcased.

-

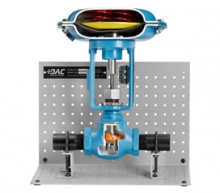

Item Number:255DDAC Worldwide's Downsized Control Valve Cutaway (255D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in the operation, construction, and maintenance of a pneumatically-operated, control valve. Through carefully planned sectioning and color-coding, the complete internal configuration of the valve is exposed and showcased. Seal features, actuator components, and hardware locations have been retained, allowing for “hands-on” training in maintenance.

-

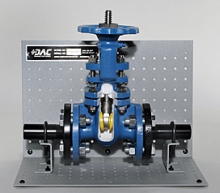

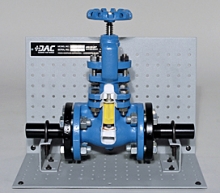

Item Number:251DDAC Worldwide's Downsized Gate Valve Cutaway (251D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in the design, construction, and maintenance of industrial gate valves. This tabletop sample supports training in a variety of process-related industries.

-

Item Number:252DDAC Worldwide's Downsized Globe Valve Cutaway (252D) is an economical yet realistic, sectioned valve sample that allows for convenient classroom training in the design, construction, and maintenance of industrial globe valves.

-

Item Number:275-160DDAC Worldwide’s Downsized Horizontal Multi-Stage Centrifugal Pump Dissectible (275-160D) is an industrial pump assembly that allows for in-depth training in the field or bench-top disassembly, inspection, troubleshooting, and assembly of multi-staged pumps.

-

Item Number:205-220DDAC Worldwide’s Downsized Right-Angle Spiral Bevel Gear Reducer Cutaway (205-220D) highlights a sectioned, small-scale industrial gear reducer for classroom and laboratory training related to mechanical drives.