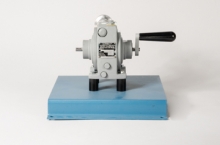

DAC Worldwide’s Transformer Wiring Training System (408-000) is a realistic training device that replicates the conditions and circumstances that an electrical worker encounters when making common power transformer connections in the field and industry. This self-contained, tabletop training system provides a safe, inexpensive, yet realistic alternative to paper-based learning without the danger of full-voltage field experience.

DAC Worldwide

World Leader in Technical Training Solutions

DAC Worldwide has been helping maintenance departments, training professionals, vocational educators, and workforce development specialists with realistic, hands-on training systems for over 35 years.

Whatever your industrial training needs, they have a wide range of products to help. For teaching fundamentals and troubleshooting, their cutaways provide a better understanding of how components actually work. The dissectibles teach essential hands-on skills for disassembly and assembly. The models allow you to explain how the various components of a system work together to create an entire process.

-

Item Number:408-000

-

Item Number:295-723DAC Worldwide's Treater Dump Valve Cutaway (295-723) is a sectioned industrial specialty oilfield valve for training in the operation, construction, and maintenance of on-off type dump valves.

-

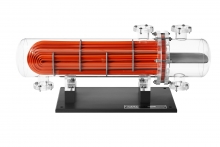

Item Number:285DAC Worldwide’s U-Tube Heat Exchanger Training Model (285) depicts a highly-detailed scale model of a common u-tube heat exchanger in a technically-accurate, professionally-crafted design. Based on a common make and model of a heat exchanger that reflects design standards established by the Tubular Exchanger Manufacturers Association (TEMA) and the ASME.

-

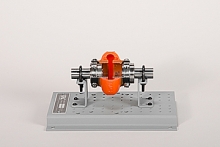

Item Number:200-2083DAC Worldwide’s Urethane Tire Coupling Cutaway (200-2083) highlights a professionally-crafted, sectioned industrial shaft coupling. The full-size, fully-detailed example gives learners a first-hand view into a component that is found in various applications worldwide and supports both instructor-led training and student self-discovery.

-

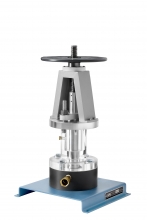

Item Number:250-000DAC Worldwide’s Valve Packing Training System (250-000) is a detailed replica of a six-inch gate valve, equipped with a backseat, which facilitates the proper removal and installation of packing.

-

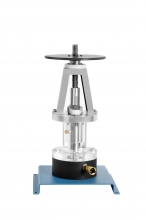

Item Number:250-PACIndustrial maintenance technicians must be familiar with a wide variety of valves used throughout many different types of industries. A common task technicians encounter on the job is replacing valve packing to prevent valves from leaking.

-

Item Number:272-718DAC Worldwide's Dissectible Variable Area Flow Meter (272-718) (rotameter) allows for close visual inspection of a common PVC and acrylic liquid flow meter to better understand its function, design characteristics, operation, and possible maintenance.

-

Item Number:205-290DAC Worldwide's Variable Speed Gear Reducer Cutaway is a sectioned variable speed industrial gear reducer. Speed variations allow for continuous variable-ratio speed adjustment of mechanical systems are still regularly encountered in industrial applications due to their durability, dependability, and consistency of operation.

-

Item Number:275-128DDAC Worldwide’s Vertical Centrifugal Pump Dissectible (275-128D) is an actual industrial centrifugal pump assembly that allows for realistic training in the field or bench-top disassembly, inspection, and reassembly of a vertical centrifugal pump.

-

Item Number:207-000DAC Worldwide’s Vertical Coupling/Shaft Alignment Training System (207-000) is a heavy-duty, precision learning system that allows for convenient, realistic training in shaft alignment. When paired with a variety of hands-on exercises, the system creates a complete performance-based course in the maintenance of shaft alignment.